DWD

page 2 DWD K04/0910

1. Contents

1. Contents........................................................................................................2

2. Note ..............................................................................................................3

3. Instrument Inspection....................................................................................3

4. Regulation Use..............................................................................................3

5. Operating Principle........................................................................................4

6. Mechanical Connection.................................................................................4

6.1 Mounting position.................................................................................4

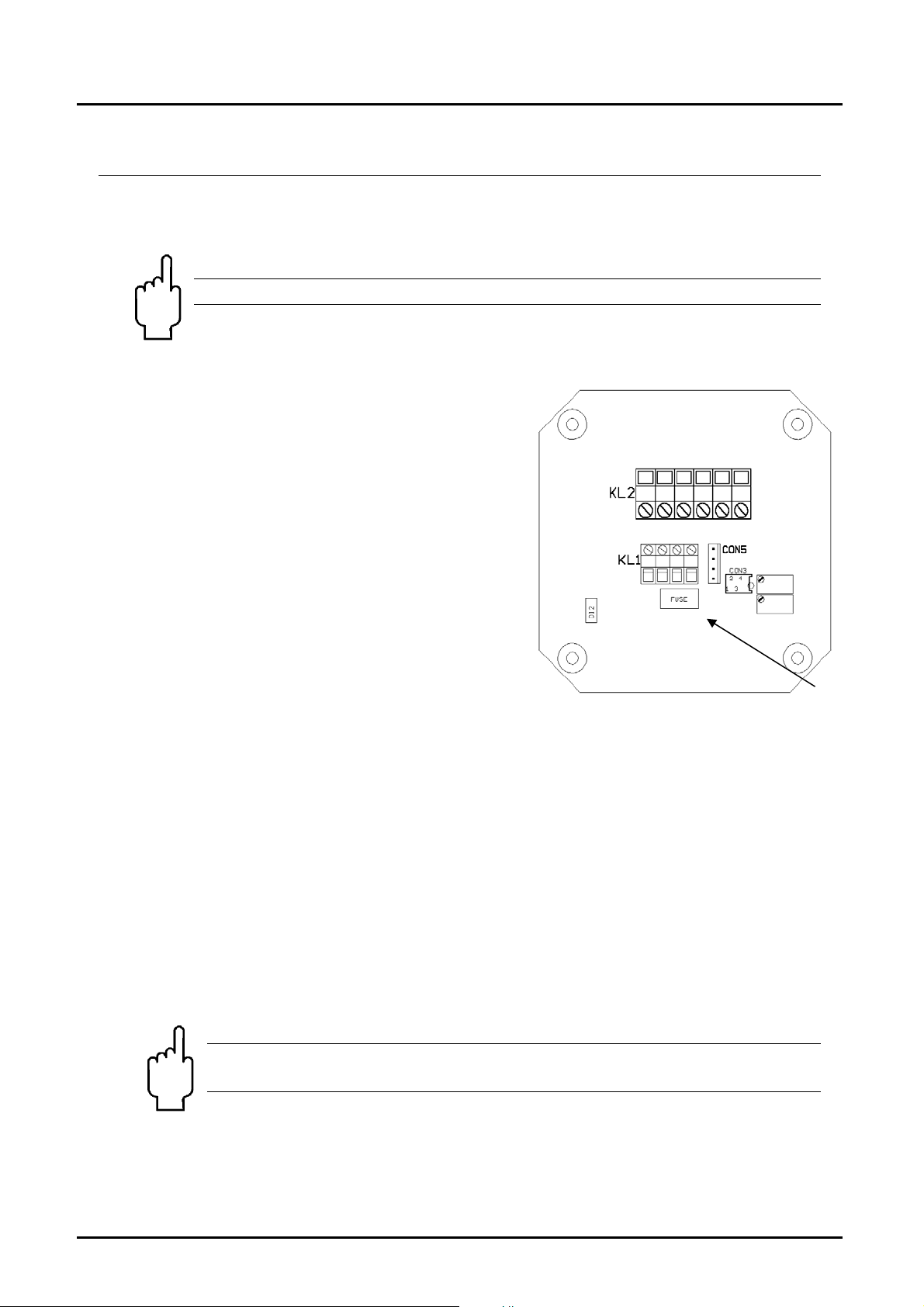

6.2 Mounting position on electronic view ...................................................4

6.3 Flow direction.......................................................................................5

6.4 Mounting position.................................................................................5

6.5 Mounting in pipe ..................................................................................5

7. Electrical Connection ....................................................................................7

7.1 General ................................................................................................7

7.2 Power supply .......................................................................................7

7.3 Analogue output...................................................................................8

7.4 Voltage output (0-10 V)........................................................................8

7.5 Frequency output.................................................................................8

7.6 Connecting the relais ...........................................................................8

7.7 Interface...............................................................................................8

8. Commissioning..............................................................................................9

8.1 Programming the device ......................................................................9

8.2 Function BATT CHECK .......................................................................9

8.3 Adjusting the switching contacts ..........................................................9

8.4 Adjusting of the output .......................................................................10

8.5 Adjusting of standard indication mode ...............................................11

8.6 Adjusting of response time.................................................................11

8.7 The totaliser .......................................................................................11

8.8 Restriction of access by code number ...............................................12

8.9 Programming the interface.................................................................12

8.10 Mounting the ferrite............................................................................12

8.11 Protection on data loss ......................................................................13

9. Technical Information..................................................................................14

10. Order Codes ...............................................................................................15

11. Maintenance ...............................................................................................16

12. Dimensions .................................................................................................16

13. Declaration of Conformance .......................................................................20

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

Internet: www.kobold.com