8

3 Inductive conductivity measurement

3.1 Range of Applications

General

The inductive measurement process allows a mostly maintenance-free acqui-

sition of the specific conductivity even in difficult medium conditions. In con-

trast to the conductive measurement process, problems like electrode

replacement and polarization do not occur.

Brief description

The device is used for the measurement/control of the conductivity/concentra-

tions of liquid media. Using it is particularly recommended in media in which

significant deposits from carried dirt, oil grease or of lime and gypsum are

expected. The integrated temperature measurement makes exact and fast

temperature compensation possible, which is particularly important for the

measurement of the conductivity. Additional functions such as the combined

switching of the measurement range and temperature coefficient make possi-

ble the optimum use in case of CIP-processes.

Two integrated switching outputs can be freely programmed for limit value

monitoring or conductivity/concentration and/or temperature. In addition,

alarm and control tasks (desalination) can be assigned.

Operation is either via a membrane keyboard and a plain text graphical display

(user language can be changed) or via a comfortable PC-Setup program. By

simply turning the housing cover, reading the display is possible both in case

of installation in vertical or horizontal pipes. By means of the Setup program,

the device configuration data can also be saved and printed for plant docu-

mentation purposes. To prevent manipulation, the device can also be supplied

without a keyboard/display. In this case, the Setup program is required for pro-

gramming.

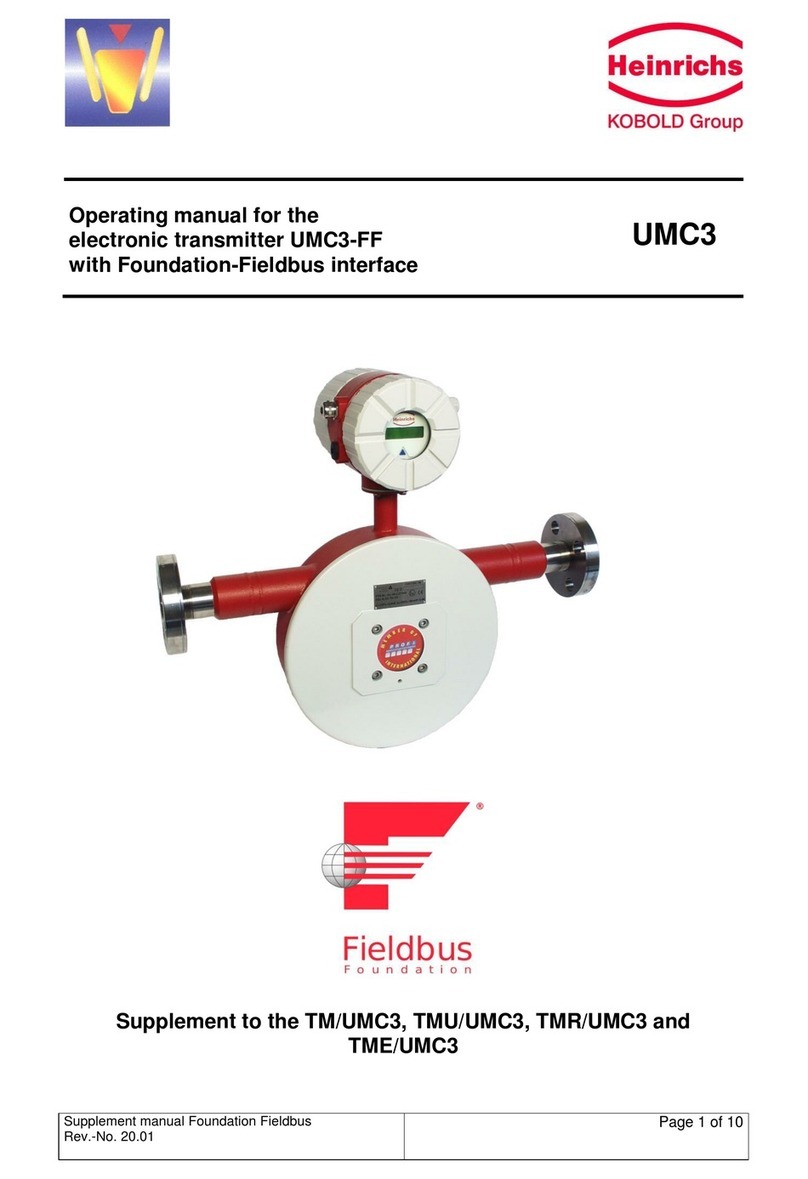

The transmitter can be supplied as a combine device (transmitter and measur-

ing cell in one device) or as a shouldered version (transmitter and measuring

cell connected by cables). The separate version is particularly suitable for

plants with intense vibrations and/or intense temperature radiation at the mea-

surement location or for installation at not easily accessible places.

Typical usage fields

• CIP-cleaning (CIP = Clean In Place/Process)

• Concentration monitoring or chemical dosing

• Foodstuffs beverages and pharmaceutical industries

•Productmonitoring(phase separation, Product/Product mixture/

Water) in the beverage industry, breweries, dairies

• Control (e.g. phase separation of cleaners/rinsing water of

cleaning processes e.g. bottle cleaning plants and in case of container

cleaning)