NMC

Page 2 DT0305

1. Content

1. Content ....................................................................................................................... 2

2. Note ............................................................................................................................ 3

3. Instrument inspection .................................................................................................. 3

4. Description .................................................................................................................. 3

5. Application .................................................................................................................. 4

6. Current simulation ....................................................................................................... 4

7. Installation .................................................................................................................. 5

8. Electrical connection ................................................................................................... 6

9. Programming .............................................................................................................. 7

9.1 Calibrating probe .................................................................................................. 7

9.2 Output Adjustment ................................................................................................ 8

9.3 Output simulate .................................................................................................... 9

9.4 Language ........................................................................................................... 10

10. Technical Data ....................................................................................................... 11

10.1 Process temperature range ............................................................................ 12

10.2 Process pressure range .................................................................................. 12

11. Safety Instructions (ATEX) .................................................................................... 13

11.1 Validity ................................................................................................................ 13

11.2 General considerations ...................................................................................... 13

11.3 Protection against ESD (electrostatic discharges) ............................................. 13

11.4 Chemical resistance ........................................................................................... 13

12. Installation in classified zone (ATEX) ..................................................................... 14

13. Label Description (ATEX) ...................................................................................... 14

14. Declaration of conformity ATEX ............................................................................. 15

15. UE Declaration of Conformity ................................................................................ 16

16. UK Declaration of Conformity ................................................................................ 17

17. ATEX Certified ....................................................................................................... 18

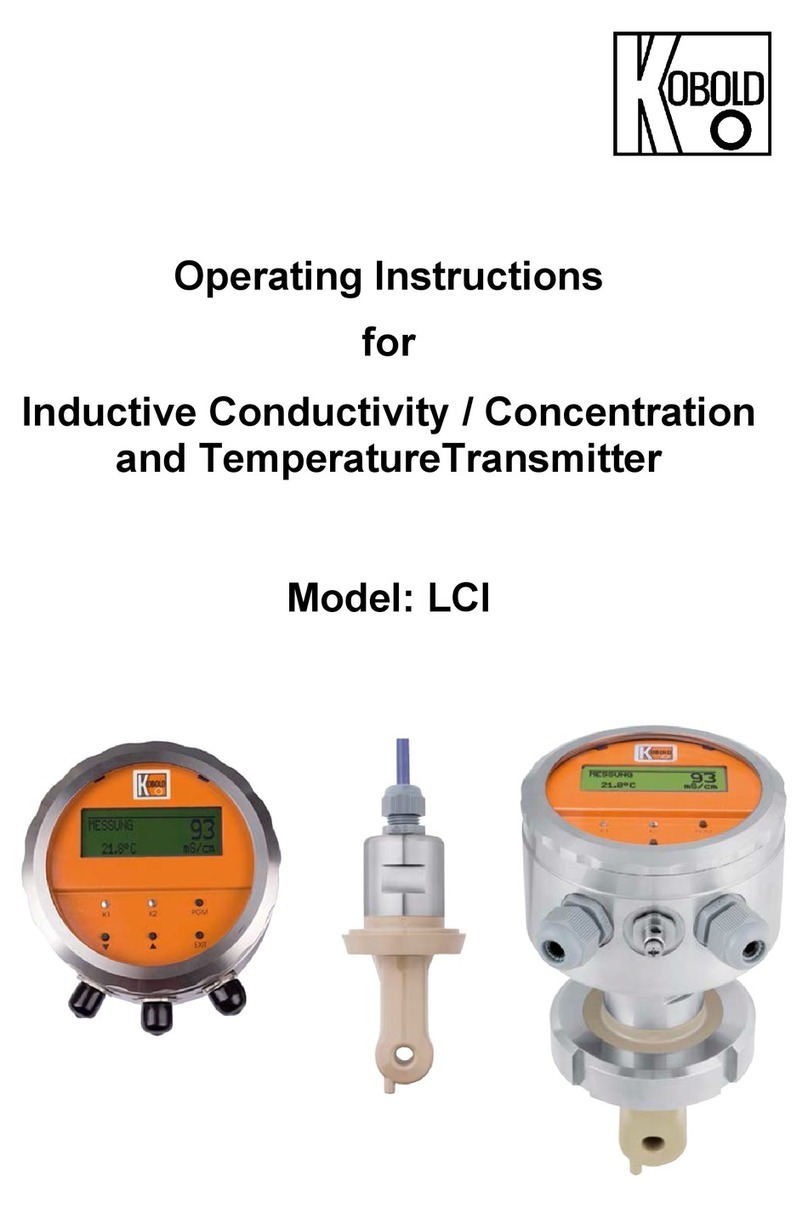

18. Models ................................................................................................................... 23

19. Order details. ......................................................................................................... 24

Manufactured by:

Kobold Mesura S.L.U

Avda Conflent Nº68 Nave 15

08915 Badalona

Tel.: +34 93 460 38 83

Fax: +34 93 460 38 72

Internet: www.kobold.com

Edition: May 2022