6

5. The operator´s clothing should be tight fitting. Avoid

wearing loose fitting clothes.

6. Keep the machine clean to prevent the danger of fire!

7. Before startingthe machineand movingoff, check the

dangerareaaroundthetractor(children!).Goodvisibility

is absolutely essential!

8. Carrying passengers on the implement during work or

transport is not permitted.

9. Makesurethattheimplementiscorrectlycoupled,and

that it is only fixed and secured with the prescribed

fittings!

10.Makesurethatthesupportingdevices,jacksetc.arein

thecorrectpositionduringassemblyanddisassembly!

11.Specialcareisrequiredwhenequipmentisbeingcoupled

to the tractor or detached from the tractor!

12.Ballast weights must always be attached in the

prescribed way at the designed attachment points!

13.Adhere to the permitted axle loads, total weights and

transportdimensions!

14.Checkandfittransportequipment–e.g.lighting,warning

signsand, ifrequired, protectiveequipment!

15.Operatingequipmentforremotecontrols(ropes,chains,

rodsetc.)mustbelaidoutinsuchawaythat,whatever

theworkingortransportposition,itcannotinadvertently

cause any movements.

16.Prepareequipmentforroadtransportasprescribedby

the manufacturer, and lock the equipment in accor-

dancewiththemanufacturer'sregulations!

17.Never leave the driver´s position when the tractor is in

motion!

18.The speed of travel must always be suited to the

environmentalconditions!Avoidanysuddenturnswhen

travelling uphill, downhill or across a slope!

19.The handling, steering and braking of the tractor is

affectedbyintegratedorattachedequipmentandballast

weights.Makesure that youallowformore flexibilityin

steeringandbraking!

20.When turning, remember to take account of the wide

loadand/orthegreaterweight oftheequipment!

Safety and Accident Prevention

Regulations

1. Take note of both the regulations in these operating

instructions and also the general safety and accident

preventionregulations!

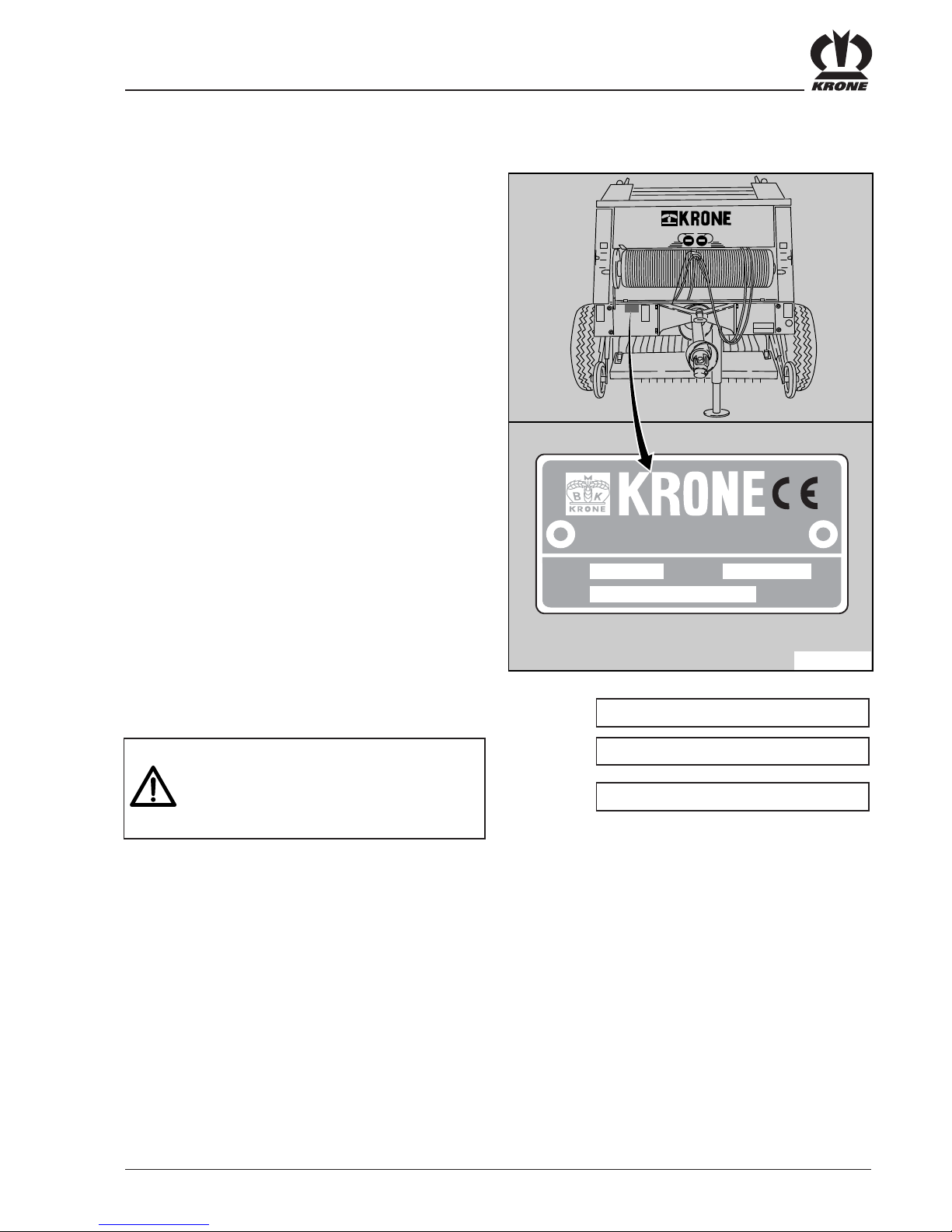

2. The attached warning and information signs give

importantadviceforsafeoperation.Observingthemwill

enhanceyour safety!

3. Whenyouusepublicroads,makesureyouobservethe

relevanttrafficregulations!

4. Makesureyouknowallequipmentandcontrolsbefore

you begin working with the machine. When you are

operating the machine, it´s too late!

Basic rule:

Before any public roads are used

and before the machine is started,

check the round baler and the tractor

for road-worthiness and operational

safety.

Operation in Accordance with

Specifications

The round baler is designed solely for normal agricultural

use(operation in accordancewithspecifications).

Anyuseofthemachineforotherpurposesisdeemedtobe

not in accordance with specifications. The manufacturer

bearsnoresponsibilityforanyresultingdamage;suchuse

is entirely at the operator´s risk.

Use in accordance with specifications also includes

adherence to the operating, maintenance and service

instructionsprescribedbythe manufacturer.

Theroundbalermustonlybeused,maintainedandrepaired

by personnel who are acquainted with the machine and

havebeen informedofthe dangersinvolved.

Theapplicableaccidentpreventionregulationsandallother

generally recognized safety, health and road traffic

regulationsmustbeadheredto.

Any unauthorized alterations to the machine render any

liabilityfordamageundertakenbythemanufacturernulland

void.

II. General