• DANGER: Because of the high working pressures developed by this gun, the possibility of grease injection into the flesh, or an eye, is a

potential hazard. Never allow any part of the human body to come in front of, or in direct contact with a grease discharge outlet or potential

hose rupture. Never point the nozzle of the gun at yourself or toward anyone else. If accidental grease injection should occur seek immediate

emergency medical attention. DO NOT try to treat the injury yourself! If injection occurs provide grease product information to medical per-

sonnel. Be certain that any and all system components will withstand the pressures being developed. Never exceed the pressure rating of any

component in the system. Inspect all hoses and fittings before each use. Weak, worn, or damaged hoses are a hazard.

• WARNING: Before each use inspect hoses for signs of wear,leaks,or loose fittings. Inspect and tighten all fluid connections regularly

and replace weak or damaged hose. Do not use any defective,unmarked, or damaged hoses. Do not repair the grease whip hose. Replace if

damaged. Most injections occur because of component rupture. Any cuts or sharp bends in hose can rupture and cause personal injury. Use

only components that will withstand the pressures being developed.

• WARNING: Do not adjust relief pressure above ,000 psi.

• WARNING: Wear safety goggles or other eye protection. Grease gun can develop high pressure- up to 000 psi (413 bar). Use safety glasses

and gloves for protection during operation. Grease leaks under pressure can penetrate the eyes and skin. Keep grease products away from

eyes. Consult grease product labeling for safety precautions.

• CAUTION: Keep hands and fingers clear of the exposed rubber or plastic portion of hose. Extreme pressure may cause nozzle extension or

hose to burst.

• CAUTION: Wipe up any dripped or spilled grease residue and keep work area clean. Grease on floor surfaces can be slippery and cause loss of

footing and possible injury.

SPECIFIC SAFETY RULES

ADDITIONAL SAFETY RULES

BEFORE USING THE BATTERY PACK AND CHARGER, READ AND UNDERSTAND ALL OF THE SAFETY

INSTRUCTIONS BELOW.

• Do not incinerate the battery pack even if it is severely damaged or is completely worn out.The battery pack can explode in a fire.

•A small leakage of liquid from the battery pack cells may occur under extreme usage or temperature conditions. If this leakage gets on your

skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water for a minimum of 15 minutes and seek

immediate medical attention. Medical note: The battery cells are rechargeable nickel-cadmium type.

•A battery operated tool with integral batteries or a separate battery pack must be recharged only with the specified charger for the battery. A

charger that may be suitable for one type of battery may create a risk of fire when used with another battery.

•Use battery operated tool only with specifically designated battery pack. Use of any other batteries may create a risk of fire. DO NOT substitute or

modify another battery to use with your grease gun. When ordering replacement battery packs, be sure to indicate the specific part number for your tool.

•Disconnect battery pack from tool or place the switch in the locked or off position before making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

• When battery pack is not in use, keep it away from other metal objects like: paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to another. Shorting the battery terminals together may cause sparks, burns, or a fire.

• Charge battery pack only in a Legacy charger made for this specific tool model.

•Do not splash battery pack or charger with water or other liquids. Do not use or attempt to charge any battery pack that has become wet or that

has had water splashed or dripped on to it.

•Do not store or use the tool and /or battery pack in locations where the temperature may reach 105° F (such as outside sheds or metal

buildings in summer).

•DANGER! Electrocution hazard! Never attempt to open the battery pack for any reason. If battery pack case is cracked or damaged, do not

insert into charger. Electric shock or electrocution may result. Damaged battery packs should be taken to a battery service center for

recycling.

•WARNING: Fire hazard. Do not store or carry battery packs so that metal objects can contact exposed battery terminals. Do not place battery

pack in aprons, pockets, tool boxes, product kit boxes, drawers, etc., along with other metal objects. Battery pack terminals could be short-circuited

causing severe burns or fire, as well as causing damage to the battery pack.

WARNING: Do not transport batteries unless exposed battery contacts are protected and insulated from materials that could contact them

and cause a short circuit.

• CAUTION: Battery pack must be securely attached to tool. If battery pack is detached, personal injury may result.

• IMPORTANT: Dispose of expended or damaged battery packs properly by returning to a local battery service dealer or contact your local

recycling agencies for proper disposal information. Under various state and local laws it may be illegal to dispose of this battery into the

municipal waste stream.

The battery pack Is not fully charged out of the carton. Read and understand all

of the safety instructions, then follow the battery charging instructions that follow.

Important Safety Instructions for Battery Pack:

NOTE: The battery pack is not fully charged out of the carton. Read and understand all of the safety instructions, and then follow the battery

charging instructions that follow.

Before using the battery pack and charger, read and understand all of the safety instructions below, and observe all of the cautionary mark-

ings on charger, battery pack, and the product using the battery pack.

• DANGER! Electrocution hazard. 120 volts are present at charger cord terminals. Do not probe with conductive objects. Electric shock or

electrocution may result.

• WARNING: Shock hazard. Do not allow any liquid to get inside charger. Electric shock may result.

• CAUTION: Burn hazard. To reduce the risk of injury, charge only Legacy 12 V battery packs that fit the charger included with this tool.

Do not attempt to charge any other battery types with this charger. Other types of batteries may burst causing personal injury and damage.

• CAUTION: Keep foreign objects out of the battery pack cavity on the charger. Metallic objects in the battery pack cavity can short the

exposed charging contacts when the charger is plugged into the power supply. Always unplug the charger when there is no battery pack in the

cavity. Unplug charger before attempting to clean.

• CAUTION: Charger is intended for use indoors only. Do not expose charger to rain, snow, or frost. Do not place charger on any wet

surfaces. Do not place charger in any location where water may drip or splash on the charger or on the surface where the charger rests.

• Pull by plug rather than by cord to remove from power supply connection to reduce risk of damage to electric plug and cord. Do not use

charger or plug charger cord into power supply if cord or plug is damaged. Have damaged cord, plug, or strain reliever replaced immediately . Do

not attempt to repair power cord or plug.

• Make sure cord is located so that it will not be stepped on, tripped over, or otherwise subjected to stress or damage.

• Do not use extension cord unless it is absolutely necessary. Use of improper extension cord could result in risk of fire, electric shock, or

electrocution. If an extension cord must be used, make sure the extension cord is properly wired and in good electrical condition. The extension

cord must have adequate wire size (AWG or American Wire Gauge) for safety. The smaller the gauge number of the wire, the greater the capacity

of the cable. For example, a 16 gauge has more capacity than 18 gauge cord.

Minimum Recommended Wire Size for Extension cords

For Total Length of Cord: 25ft (7.6m) to 50ft (15.2 m) --use 18 gauge minimum cord size.

75 ft (22.9 m) to 1 00 ft (30.5 m) -- use 16 gauge minimum cord size.

125ft (38.1 m) to 150ft (45.7 m)- use 14 gauge minimum cord size.

175ft (53.3 m)- use 12 gauge minimum cord size.

•The charger is designed to operate on standard 120 V AC electrical power. Do not attempt to use it on any other voltage.

• Do not place any object on top of charger or place the charger on a soft surface that might interfere with proper air

circulation around and under the charger to avoid excessive internal heat. Place the charger in a position away from any

heat source.

•Do not operate the charger if it has received a sharp blow, been dropped, or otherwise damaged in any way. Replace

the charger or take it to an authorized service center.

Important Safety Instructions for Charger:

Symbols

DC ........ .. ........ direct current

.. ............ .. ... direct current symbol

V .. ........ .. .. .... .. volts

Hz .......... .. .. .. .. hertz

psi. .. .... .. ...... .. .. pounds per square inch (units of pressure)

AC ... .... .... .. .... . alternating current

UL .. ......... ...... . Underwriter’s Laboratories listing on charger

+ .. ........... .. .. .... Positive terminal on battery pack and charger

-.... .......... .. .. ..... Negative terminal on battery pack and charger

UL745-3 ................... UL Standard for Safety for Battery-Operated Tools

This product is listed in lntertek's

Directory of listed US Products

Specifications

nuGesaerGderewoP-yrettaBCDV210831L:ledoM

Maximum Operating Pressure:

Continuous pressure: 4000 psi

Intermittent pressure: 6000 psi

Grease Reservoir Capacity:

14.5 oz cartridge

16 oz bulk

Lubricant (grease): Up to NLGI #2

Battery Capacity: 1300 milliamp hours

Battery Quick Charge: 1 hour

Charger Input Power Source: 120 V AC

Functional Description

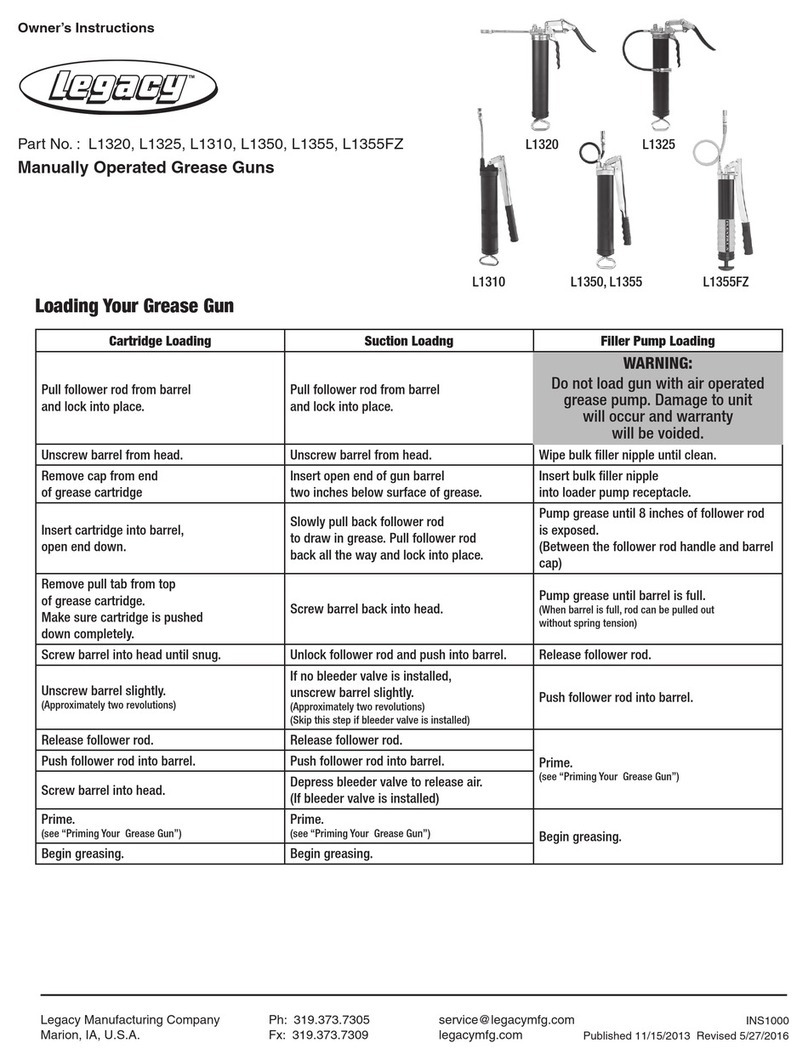

The Legacy Workforce 12V DC battery-powered, cordless grease gun allows convenient high-pressure greasing at grease pressures up to 6000 psi,

without an air hose, utilizing a motor and set of gears to develop pressure for dispensing grease as a single-action, positive displacement pump. The

gun is operated (after grease loading) by squeezing the trigger to dispense grease either freely from the grease nozzle (standard zerk coupler) or by

engaging the grease couple onto standard grease zerk fittings on equipment and machinery for high-pressure greasing. The gun is equipped with a

pressure-relief valve to limit grease pressure to 6000 psi to reduce risk of motor overload and tool damage. Additionally, a manually-operated air

pocket valve helps bleed trapped air in the grease barrel to make priming faster and easier. Do not exceed specifications or alter gun to perform

beyond ratings. Suchmisuse will void warranty.

311253 4