2

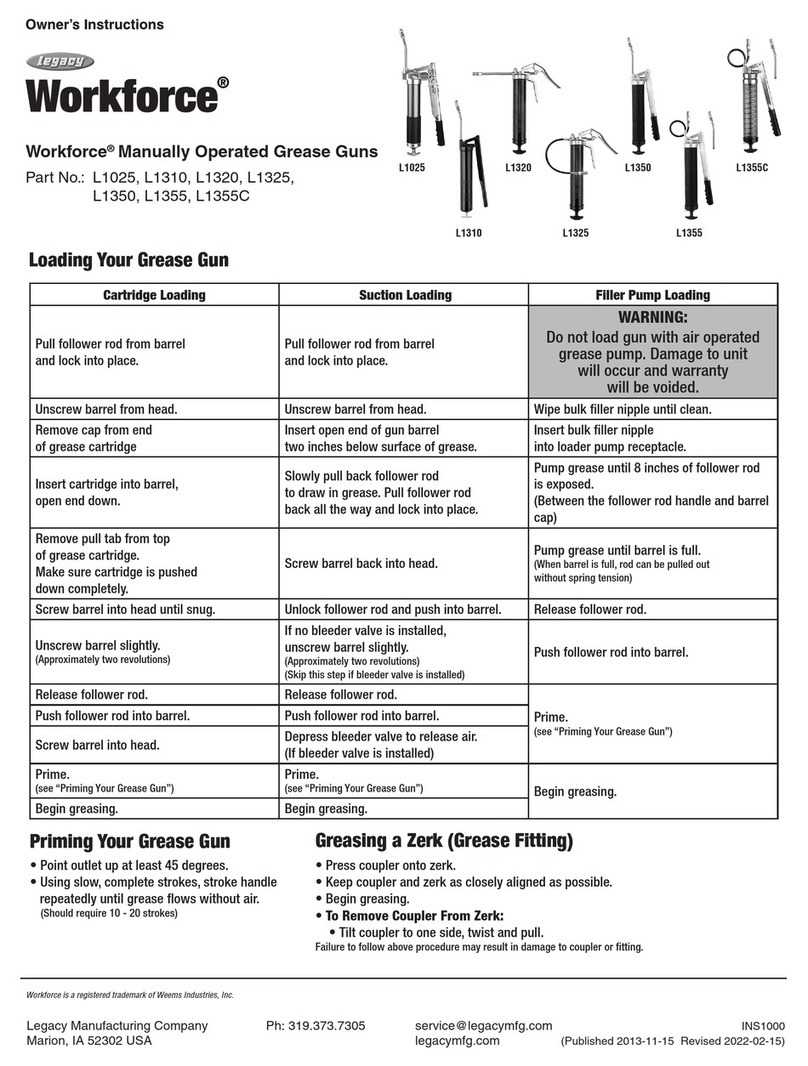

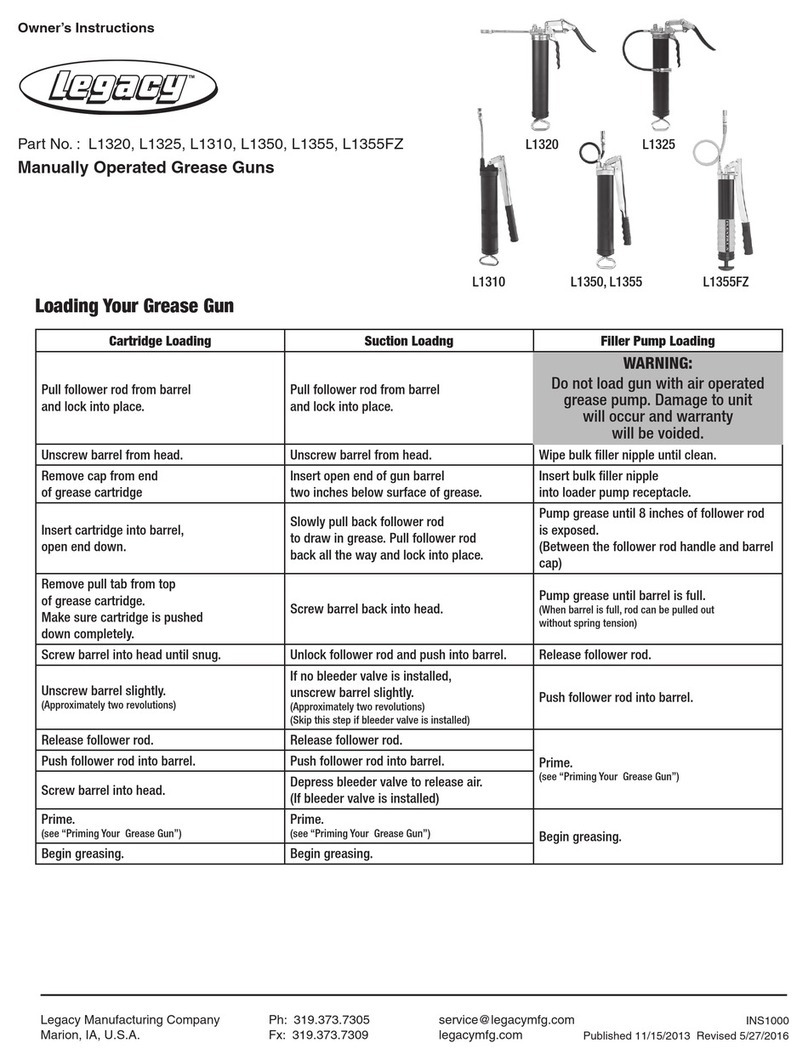

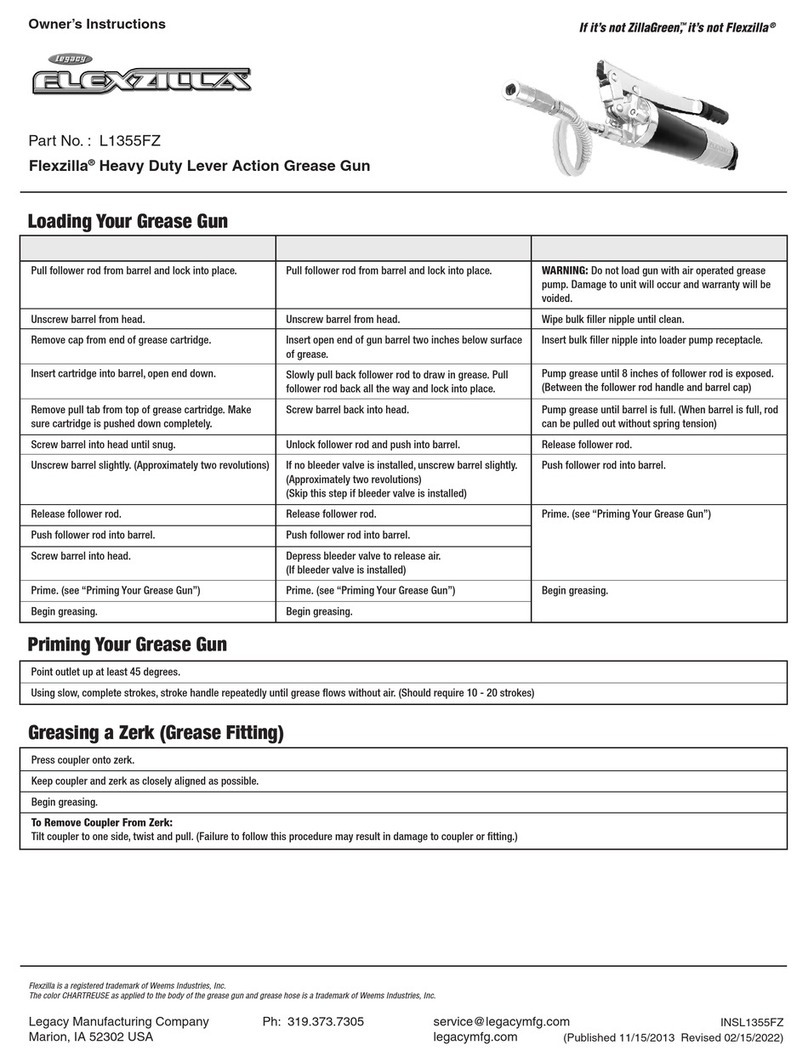

Manual Grease Filler Pump Loading Procedure

1. Make sure the barrel follower rod is unlocked and pushed in.

2. Wipe bulk filler nipple clean.

3. Insert the grease gun bulk filler nipple into loader pump / transfer pump

receptacle.

4. Pump grease until you reach a distance of 8 inches between the follower

rod handle and the black barrel cap.

Suction Loading Procedure

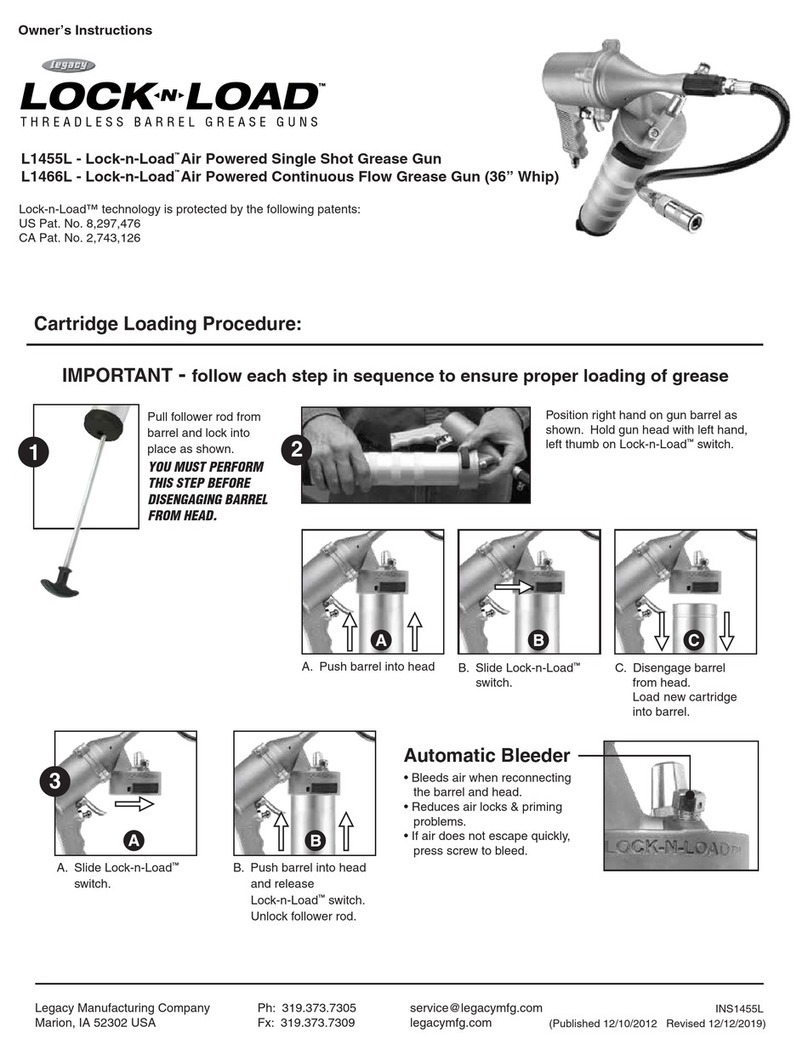

1. See step 1-2 on previous page to disengage gun barrel.

2. Insert open end of gun barrel two inches below surface of grease.

3. Slowly pull back plunger rod handle (drawing in grease).

4. See step 3 on previous page to engage barrel into head assembly.

5. Unlock follower rod by pressing tab. Continue pressing tab to push

the rod in the remaining distance.

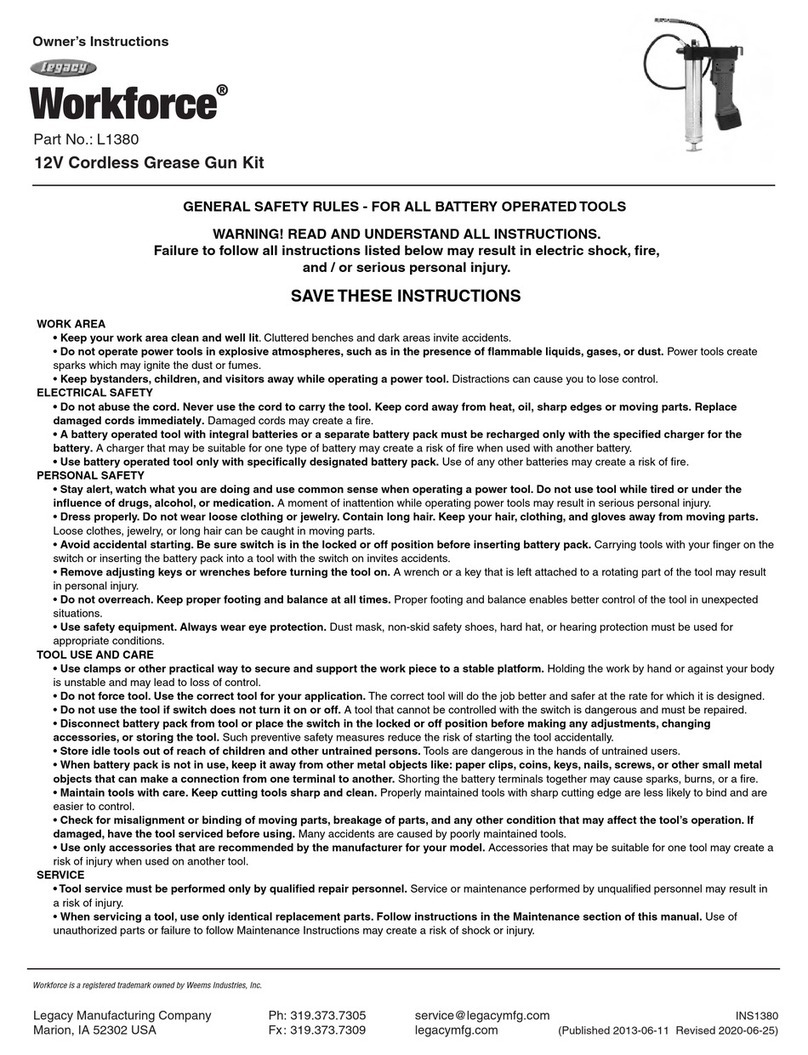

The L1045L and L1075L spring loaded handle and storage hook are designed to make it easy to

engage grease fittings in tight spaces:

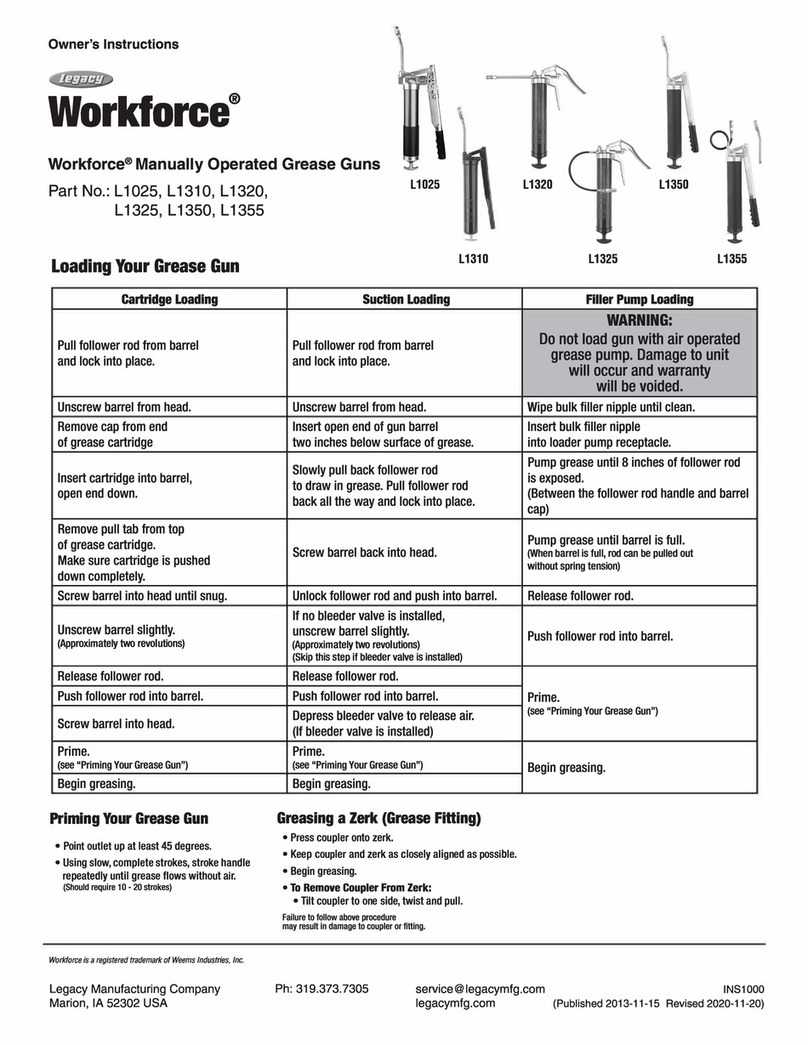

One Handed Operation:

1. Connect coupler to grease fitting with one hand while gripping grease gun like a pistol grip gun

(FIG C).

2. Squeeze handle to create pressure (the pressure will engage the grease coupler to the fitting).

3. Resume normal (two handed) greasing.

To secure the grease lever:

1. Press handle down as if greasing (Note: Gun may expel grease during this step).

2. Slide handle latch over storage hook (FIG. D).The L1045L is equipped with a handle lock to

help prevent accidental grease discharge during storage or while maneuvering or loading the gun.

To release the latch:

1. Press and release the handle.

BULK LOADING PROCEDURES

ONE HANDED OPERATION & HANDLE LOCK

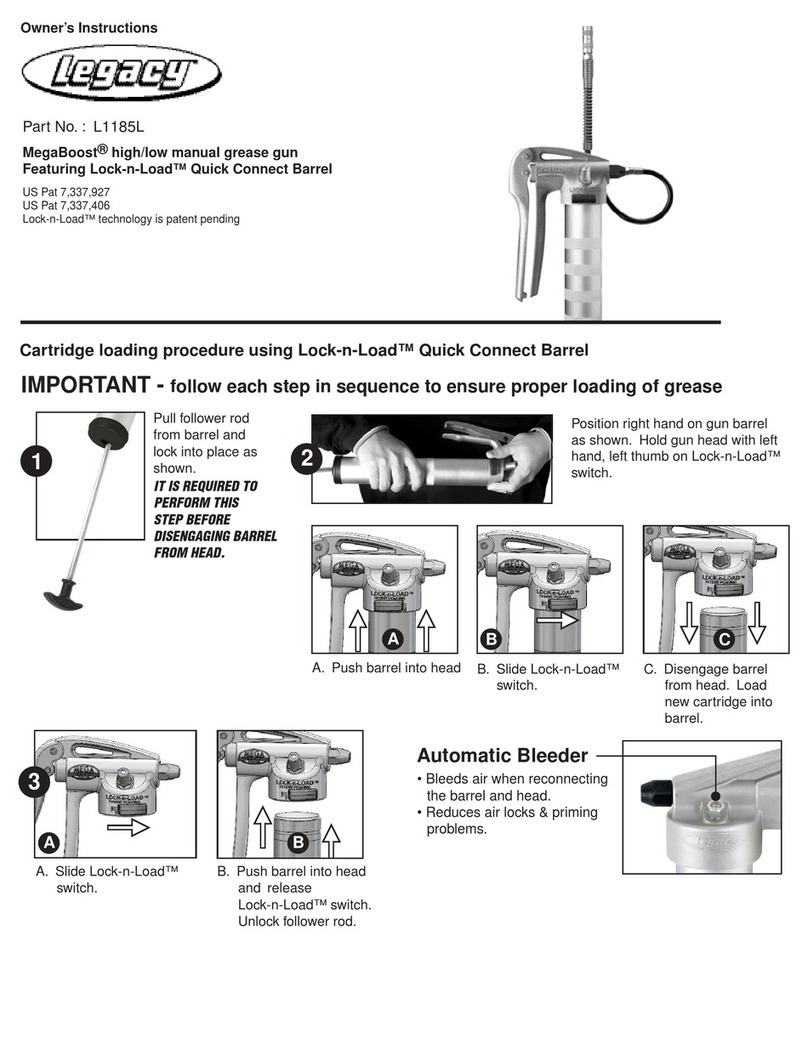

1. If air is not heard passing through auto bleeder when removing or

installing barrel:

a. Slide Lock-n-Load switch and push the empty barrel (with follower

rod unlocked) into gun head.

b. Pull follower rod and lock (clears the auto bleeder).

c. Disengage barrel from head (clears the auto bleeder).

d. Repeat until auto bleeder is cleared.

e. Contact Legacy Manufacturing.

2. If when assembling the barrel to head seems difficult or springy:

a. Always push Lock-n-Load switch forward as far as possible.

b. Grease cartridge may not be inserted completely into barrel.

c. Excess grease may be in head.

• Remove excess grease.

d. Auto bleeder may be plugged.

3. Grease does not flow when handle is stroked:

a. Release follower rod and push up if it doesn’t automatically go up.

b. Grease cartridge may be empty.

c. See best “Lock-n-Load Best Practices”:

“Priming after refilling with grease”.

IMPORTANT! Read all instructions and warnings before operating this product. SAVE THESE INSTRUCTIONS!

IMPORTANT! Do not load gun with air-operated grease pump. Damage to unit will occur and warranty will be voided.

OPERATING TIP: The Automatic bleeder will expel air pockets when reconnecting the barrel and head, this will greatly reduce air locks and priming problems.

WARRANTY

LEGACY MANUFACTURING COMPANY (“LEGACY”) warrants that this equipment will be free from defects in material and workmanship for a period of one (1) year from the

date of purchase, under normal use. LEGACY’S sole obligation under this warranty is limited to replacing or repairing, free of charge, any equipment that proves to be defective

under normal conditions and use according to the recommendations of LEGACY. To obtain repair or replacement, the equipment must be shipped to a LEGACY authorized

Warranty and Service Center during the warranty period, transportation charges prepaid, with proof of date of purchase. In the event of repair or replacement, the warranty

period shall not be extended beyond the original warranty period.

While necessary maintenance or repairs on your Legacy equipment can be performed by any company, we recommend that you use only authorized Legacy service centers.

Improper or incorrectly performed maintenance or repair voids this warranty. Contact us at service@legacymfg.com or www.legacymfg.com/instruction-manuals/ for installation

instructions.

Recommended method for

holding grease gun to disengage

barrel.

TROUBLESHOOTING GUIDE

WARNINGS / TIPS / WARRANTY

• Immediately reassemble barrel to head.

• Release follower rod.

• Press auto bleeder valve until all air escapes (FIG B.).

5. Re-filled cartridges, before attempting to grease:

a. Repeat the load process to extract air from grease.

• Pull follower rod and lock.

• Disengage barrel from head.

• Immediately reassemble barrel to head.

• Release follower rod.

• Press auto bleeder valve until all air escapes (FIG B.).

6. Priming after refilling with grease:

a. Release follower rod and push rod up if it doesn’t automatically go up.

b. Point outlet up at least 45 degrees.

c. If using flexible extension, raise coupler above outlet.

d. Cover coupler outlet with thumb or finger.

e. Stroke handle completely and repeatedly until grease flows without air.

LOCK-N-LOAD™BEST PRACTICES (CONT.)

FIG. A FIG. B FIG. C FIG. D