Contents i

l5

EDS84DG752 EN 7.0

5.7 Wall mounting 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Installation instructions 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Wall adapter for 0.37...3.0kW 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.3 Wall adapter for 4...7.5kW 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.4 Frame Unit / Field Package without switch 90. . . . . . . . . . . . . . . . . . . . . . . .

5.7.5 Frame Unit / Field Package with switch 90. . . . . . . . . . . . . . . . . . . . . . . . . .

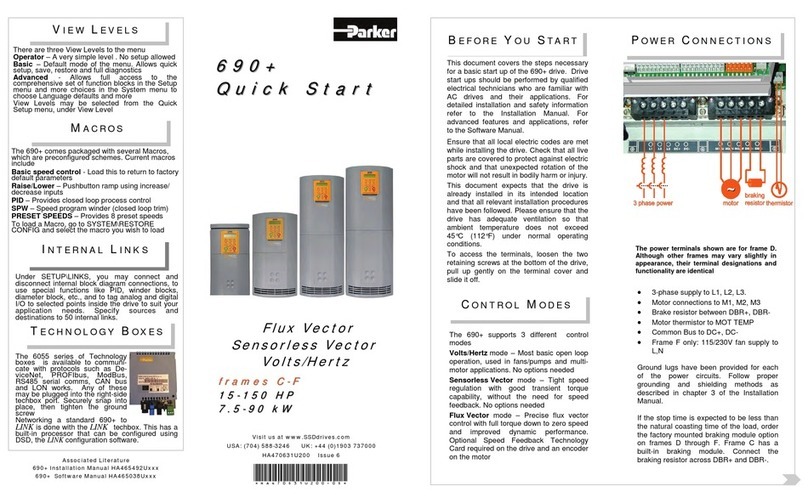

5.8 Power terminals 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Control terminals 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.1 Basic I/O 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.2 Standard I/O 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.3 Extended I/O 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.4 AS−Interface 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.5 AS−Interface STO 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.6 CANopen® 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.7 CANopen® STO 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.8 EtherCAT® 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.9 EtherCAT® STO 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.10 EtherNet/IP 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.11 EtherNet/IP STO 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.12 PROFIBUS® 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.13 PROFIBUS® STO 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.14 PROFINET® 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.15 PROFINET® STO 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

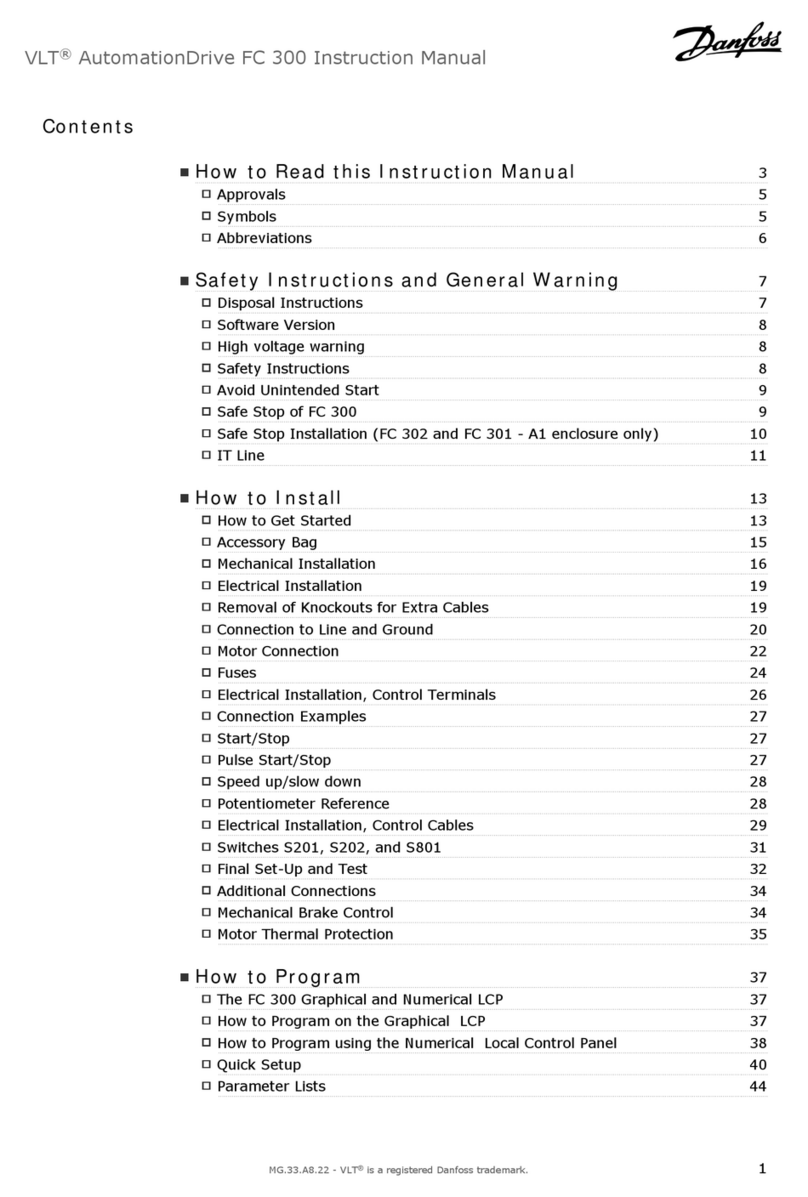

6 Commissioning 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before you start 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Handling the memory module 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Commissioning via DIP switch/potentiometer 125. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 DIP switch / potentiometer assignment 0 128. . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 DIP switch / potentiometer assignment 1 131. . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Before switching on 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.4 Commissioning steps 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

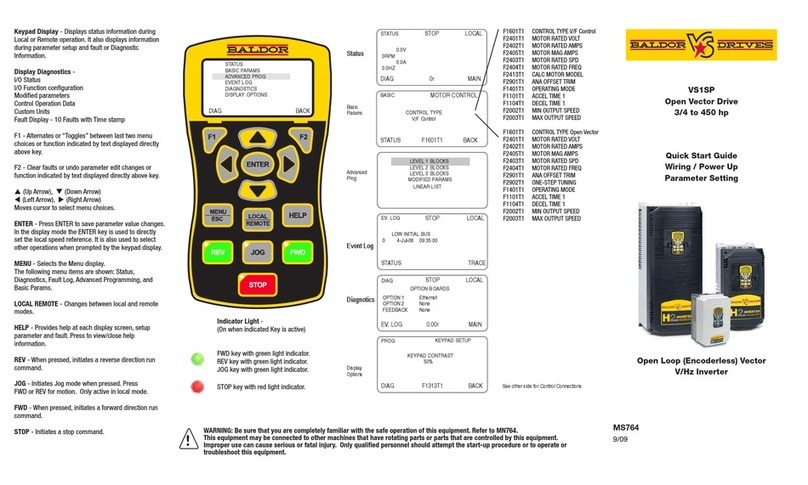

6.4 Commissioning via the diagnosis terminal 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Display elements and function keys 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Menu structure 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 User menu 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.4 Commissioning steps 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.5 SET mode 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Diagnostics 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Braking operation 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Braking operation without additional measures 146. . . . . . . . . . . . . . . . . . . . . . . . . . .