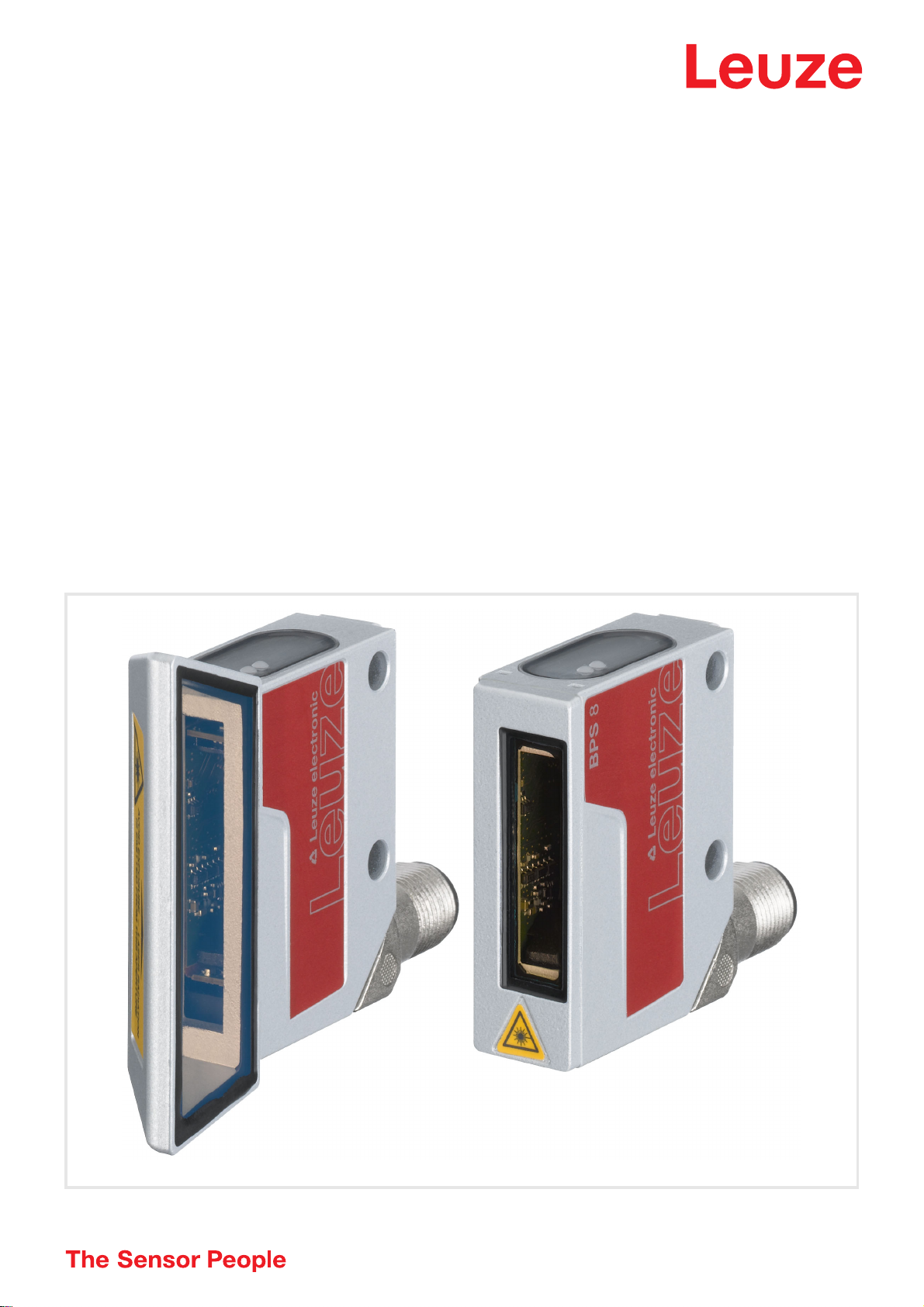

Leuze electronic GmbH + Co. KG BPS 8 4

8 Configuration / device parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1 RS 232/RS 485 interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2 BPS Configuration Tool software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2.1 Installation of the BPS Configuration Tool software . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2.2 Brief manual for the BPS Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2.3 Setting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3 Service operating mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3.1 Activate service interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3.2 Connecting the service interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3.3 Overview of commands and parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.4 Overview of the parameter structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.5 Detailed description of the tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5.1 Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5.2 Position detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.5.3 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.5.4 Switching input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.5.5 Switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9 Protocols for position value output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1 Binary protocol 1 – BPS 8 SM 10x-01 / BPS 8 SM 10x-05 . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1.1 Data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1.2 Request telegram to the BPS 8 SM 10x-01 / BPS 8 SM 10x-05. . . . . . . . . . . . . . . . . . 62

9.1.3 BPS 8 SM 10x-01 / BPS 8 SM 10x-05 response telegram . . . . . . . . . . . . . . . . . . . . . . 63

9.2 Binary protocol 2 – BPS 8 SM 10x-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.2.1 Data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.2.2 Request telegram to the BPS 8 SM 10x-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.2.3 BPS 8 SM 10x-02 response telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.3 Binary protocol 3 – BPS 8 SM 10x-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.3.1 Data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.3.2 Request telegram to the BPS 8 SM 10x-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.3.3 BPS 8 SM 10x-03 response telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.4 Binary protocol 4 – BPS 8 SM 10x-04 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.4.1 Data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.4.2 Request telegram to the BPS 8 SM 10x-04 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.4.3 BPS 8 SM 10x-04 response telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.4.4 Binary protocol 4 request sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.5 Binary protocol 6 – BPS 8 SM 10x-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.5.1 Data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

9.5.2 Request telegram to the BPS 8 SM 10x-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

9.5.3 BPS 8 SM 10x-10 response telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.1 Operating indicators of the LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.2 General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.3 Error on the interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.2 Repairs, servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.3 Disassembling, packing, disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12 Type overview and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.1 Type overview: BPS 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.2 Type overview: Bar code tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88