Original Instructions ESB200

ESB2x series, E-Stop button acc. to EN ISO 13850 and

EN 60947-5-5

Leuze electronic GmbH + Co. KG

In der Braike 1, D-73277 Owen - Teck / Germany,

Phone: +49 7021 573-0, Fax: +49 7021 573-199,

1 Safety and use

This document is to be adhered to for installation, start-up/use and

testing of the ESB2x. It must be provided to the affected personnel.

As before, all relevant national and international standards and regu-

lations must be observed, including

• Machinery directive 2006/42/EC

• Low voltage directive 2006/95/EC safety regulations

• Accident-prevention regulations and safety rules

• Ordinance on Industrial Safety and Health and Labor Protection

Act

• Device Safety Act

The manufacturer and operator of the machine are responsible for

the proper use, monitoring and testing of the ESB2x E-Stop button

as well as compliance with all applicable safety regulations,

including:

• EN ISO 13850: 2008

• EN 60947-5-1:2004

• EN 60947-5-5:1997 and Annex 2005

2 Device description and function

Usingthe2NC/1NOcontactblock,theESB2xE-Stopbuttonsenable

electrical E-Stop command output up to and including safety

category 4 and PL e. They are designed acc. to EN ISO 13850:2008

regarding color, shape and symbols. ESB2x are available with rotary

or key release. Connection can be done either via cable or M12 plug.

3 Mounting and connection

Screw the housing base tightly to the force-fit surface.

Break the provided cable bushing free.

Lead through the cable gland with the corresponding sealing

class and screw it in firmly.

Lead the cable in and screw it in firmly with the fixing nut.

Connection = E-Stop command output to 2 x NC, signaling to

NO.

Place the upper housing on the lower part and screw it on firmly.

Put the caps on.

Observe the technical data.

4 Tests

First checks

The ESB2x is force-fit fastened acc. to specifications. Rotation is

therefore not possible.

Switch on the machine.

Press the button.

WARNING

The system is to be brought to a standstill safely and safe-

guarded against re-starting before mounting and connection.

1

1

3

2

2

4

3

4

1

7

8

2

6

5

Pin 3

Pin 5

Pin 7

Pin 4

Pin 6

Pin 8

WARNING

Severe accidents may result if tests are not performed prop-

erly.

Make certain that there are no people in the danger zone.

Check that the machine has stopped.

Recurring checks

Check that the ESB2x and cable fastenings are free from play

and manipulation and that they function properly.

5 EC Declaration of Conformity

You can find the EC Declaration of Conformity with the standards

used at Leuze website.

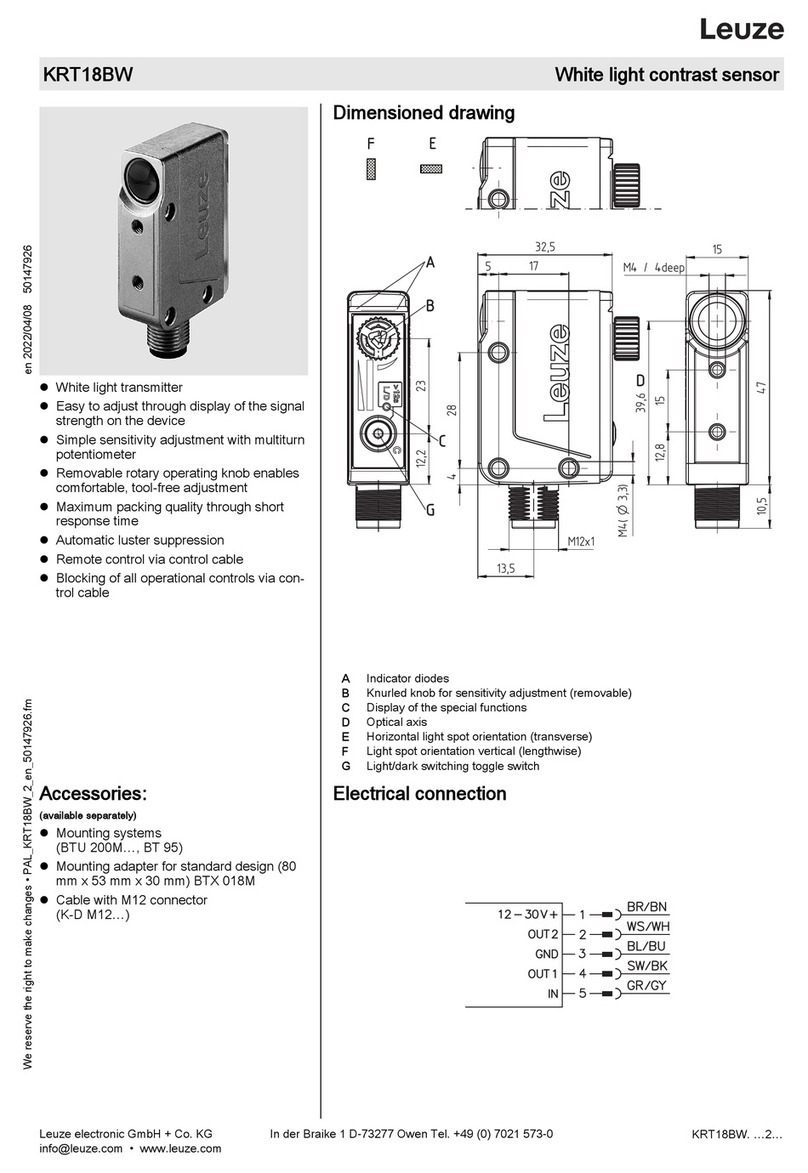

6 Dimensional drawings

7 Technical data

Ø40

101,8

2,8

80

72

Ø60

58,5

66,5

80

72

Ø40

102,3

Integration in accordance with EN 62061,

IEC 61508 up to SIL 3

Integration in accordance with

EN ISO 13849-1 up to PL e, up to cat. 4

Number of switching cycles to dangerous

failure (B10d)600,000

Service life (TM) 20 years

Temperature range, operation -25°C to +80°C

Dirt level in accordance with EN 60947-1 3

Safety class II

Certifications cULus

Mechanical life time in accordance with

EN ISO 13849-1 300,000

Mechanical life time, contact (without load) 20,000,000

Actuation frequency in accordance with

IEC 60947-5-1 max. 3600 per hour

Contact allocation 2NC/1NO

Switching principle Creep contact

Contact opening Force-fit

Contact material Silver alloy

“Stop” inscription 60 mm screen

Actuation force, red button 25 N

Mounting Structure

Head / housing color red/yellow-black

Button/housing material PA/PC

Type of fastening passageway fastening

Protection class IP67, IP69K