R, P, B, and M Series

Surge Protective Devices

INSTALLATION INSTRUCTIONS ENGLISH

PK-A3478-10-00-4A

WARNINGS:

• HAZARD OF ELECTROCUTION AND SHOCK. CAREFULLY READ AND FOLLOW INSTRUCTIONS.

• Only electricians should install or service Surge Protective Devices (SPDs).

• Hazardous voltages exist within SPDs.

• SPDs should never be installed or serviced when energized.

• Use appropriate safety precautions including Personal Protection Equipment.

• Failure to follow these instructions can result in death, serious injury, and/or equipment damage.

• Read this manual in its entirety prior to installing.

Bonding and Grounding Hazard

Verify that the neutral conductor in the service entrance equipment is bonded to ground in accordance with the National Electric Code (NEC®)

and all applicable codes. During installation into an electrical system the SPD must not be energized until the electrical system is completely

installed, inspected and tested. All conductors must be connected and functional including the neutral (if required).

The voltage rating of the SPD and system must be veried before energizing the SPD. Failure to follow these guidelines can lead to abnormally

high voltages at the SPD. This may cause the SPD to fail. The warranty is voided if the SPD is incorrectly installed and/or if the neutral conductor

in the service entrance equipment or downstream of separately derived systems is not bonded to ground in accordance with the NEC.

Do Not Hi-Pot Test SPDs

Any factory or on-site testing of power distribution equipment that exceeds normal operating voltage such as high-potential insulation testing, or

any other tests where the suppression components will be subjected to higher voltage than their rated Maximum Continuous Operating Voltage

(MCOV) must be conducted with the SPD disconnected from the power source. For 4-wire systems, the neutral connection at the SPD must also

be disconnected prior to performing high-potential testing. Failure to disconnect the SPD and associated components during elevated voltage

testing will damage the SPD and will void the warranty.

CAUTIONS:

SPDs on Ungrounded Systems

Ungrounded systems are inherently unstable and can produce excessively high line-to-ground voltages during certain fault conditions. During

these fault conditions, any electrical equipment, including an SPD, may be subjected to voltages which exceed their designated ratings. An SPD

designated specically for ungrounded systems should be used.

Unpacking and Preliminary Inspection

Inspect the entire shipping container for damage or signs of mishandling. Remove the packing materials and further inspect the unit for any

obvious shipping damages. If any damage was found, and is a result of shipping or handling, immediately le a claim with the shipping company

and forward a copy to Leviton at industrial@leviton.com.

Storage Environment

This SPD should be stored in a clean, dry environment. Storage temperature range is -49°F to 140°F (-45°C to 60°C). Avoid exposure to

high condensation.

© 2023 Leviton Mfg. Co., Inc.

1

Pre-Installation

Operating Environment

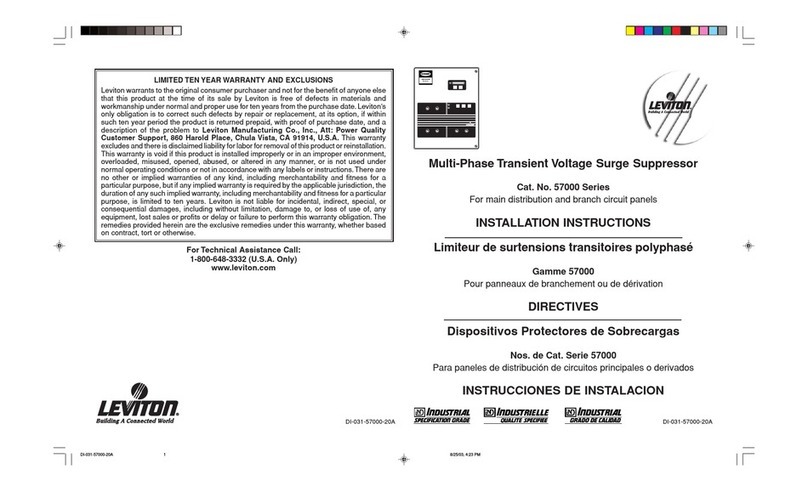

Series R, P, and B are NEMA 4X enclosures and Series M is NEMA 4 enclosure. Before installing, ensure that your enclosure type and

application are appropriate with regard to moisture, dirt, excessive dust, ammable materials or atmospheres, corrosive vapors, etc. Please

consult factory if enclosure needs to be changed. The R and P Series are designed to work in a temperature range of -31°F to +185°F (-35°C to

+85°C), and the B and M Series -40°F to +185°F (-40°C to +85°C) with a relative humidity of 0% to 95% (noncondensing). Excessive temperature

may inadvertently operate internal thermal over-temperature protectors.

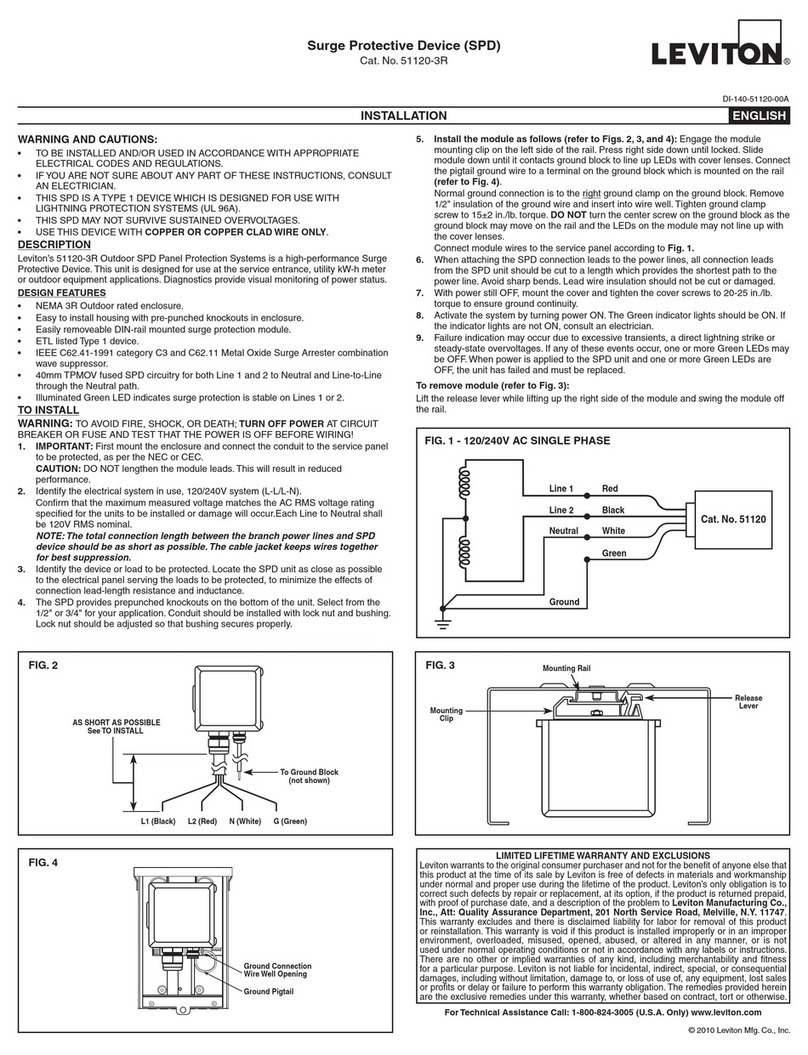

Line Side versus Load Side Installation

The R and P Series SPDs are Type 1, and the B and M Series SPDs are Type 2, as dened in UL 1449 and the National Electrical Code. Type 1

SPDs are intended to be installed on the line side of the service disconnect overcurrent device but may also be installed on the load side. Type 2

SPDs are intended to be installed on the load side of the service disconnect overcurrent device.

NOTE: Devices with UL1293 Filtering are qualied to the same standards, but can only be installed as Type 2 devices per UL specication.

Audible Noise

SPD background noise is negligible or non-existent, and does not restrict the location of installation.

4

For Technical Assistance Call: 1-800-824-3005 (USA Only) or 1-800-405-5320 (Canada Only)

www.leviton.com

FOR CANADA ONLY:

For warranty information and/or product returns, residents of Canada should contact Leviton in writing at Leviton Manufacturing of Canada

ULC to the attention of the Quality Assurance Department, 165 Hymus Blvd, Pointe-Claire (Quebec), Canada H9R 1E9 or by telephone

at 1-800-405-5320.

LIMITED 5 YEAR WARRANTY AND EXCLUSIONS

Leviton warrants to the original consumer purchaser and not for the benet of anyone else that this product at the time of its sale by Leviton is free

of defects in materials and workmanship under normal and proper use for ve years from the purchase date. Leviton’s only obligation is to correct

such defects by repair or replacement, at its option. For details visit www.leviton.com or call 1-800-824-3005. This warranty excludes and

there is disclaimed liability for labor for removal of this product or reinstallation.This warranty is void if this product is installed improperly or in an

improper environment, overloaded, misused, opened, abused, or altered in any manner, or is not used under normal operating conditions or not

in accordance with any labels or instructions. There are no other or implied warranties of any kind, including merchantability and tness

for a particular purpose, but if any implied warranty is required by the applicable jurisdiction, the duration of any such implied warranty, including

merchantability and tness for a particular purpose, is limited to ve years.Leviton is not liable for incidental, indirect,special,or consequential

damages, including without limitation, damage to, or loss of use of, any equipment, lost sales or prots or delay or failure to perform this

warranty obligation.The remedies provided herein are the exclusive remedies under this warranty, whether based on contract, tort or otherwise.

FCC STATEMENT:

This device complies with Part 15 of the FCC Rules and ISED License-exempt RSS standard(s). Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) This device must accept any interference received, including interference

that may cause undesired operation. Changes or modications not expressly approved by Leviton could void the user’s authority to operate

the equipment.

These limits are designed to provide reasonable protection against harmful interference in a commercial installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

-

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

This Class A digital apparatus complies with Canadian CAN ICES-3(A)/NMB-3(A).

FCC SUPPLIER’S DECLARATION OF CONFORMITY:

Models R, B, P, and M Series Surge Protective Devices are sold by Leviton Manufacturing Inc. 201 N Service Rd, Melville, NY 11747. This device

complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesired operation.

TRADEMARK DISCLAIMER:

Use herein of third party trademarks, service marks, trade names, brand names and/or product names are for informational purposes only,

are/may be the trademarks of their respective owners; such use is not meant to imply affiliation, sponsorship, or endorsement.