LGMG North America Inc. Maintenance Manual

3

1.1 Compliance

1) You accept the proper training of safety

operation and machine maintenance, and

have corresponding aptitudes.

2) It is necessary to read, understand and

adhere to all safety regulations of this

manual, safety regulations of workplace

and applicable laws and regulations of

government.

3) Protective articles, such as safety helmet,

safety belt, work shoes, goggles and

protective clothing, have been equipped all

over the body, and the physical state is

excellent.

4) Operators can only conduct conventional

inspection and maintenance items as

specified in this manual.

5) Only technical maintenance personnel who

are trained and get corresponding

certificates may complete scheduled

maintenance.

6) Waste and old materials shall be disposed

according to government regulations and

work site rules.

7) Only LGMG North America approved parts

and consumables can be used.

8) Function test shall be always conducted

upon maintenance.

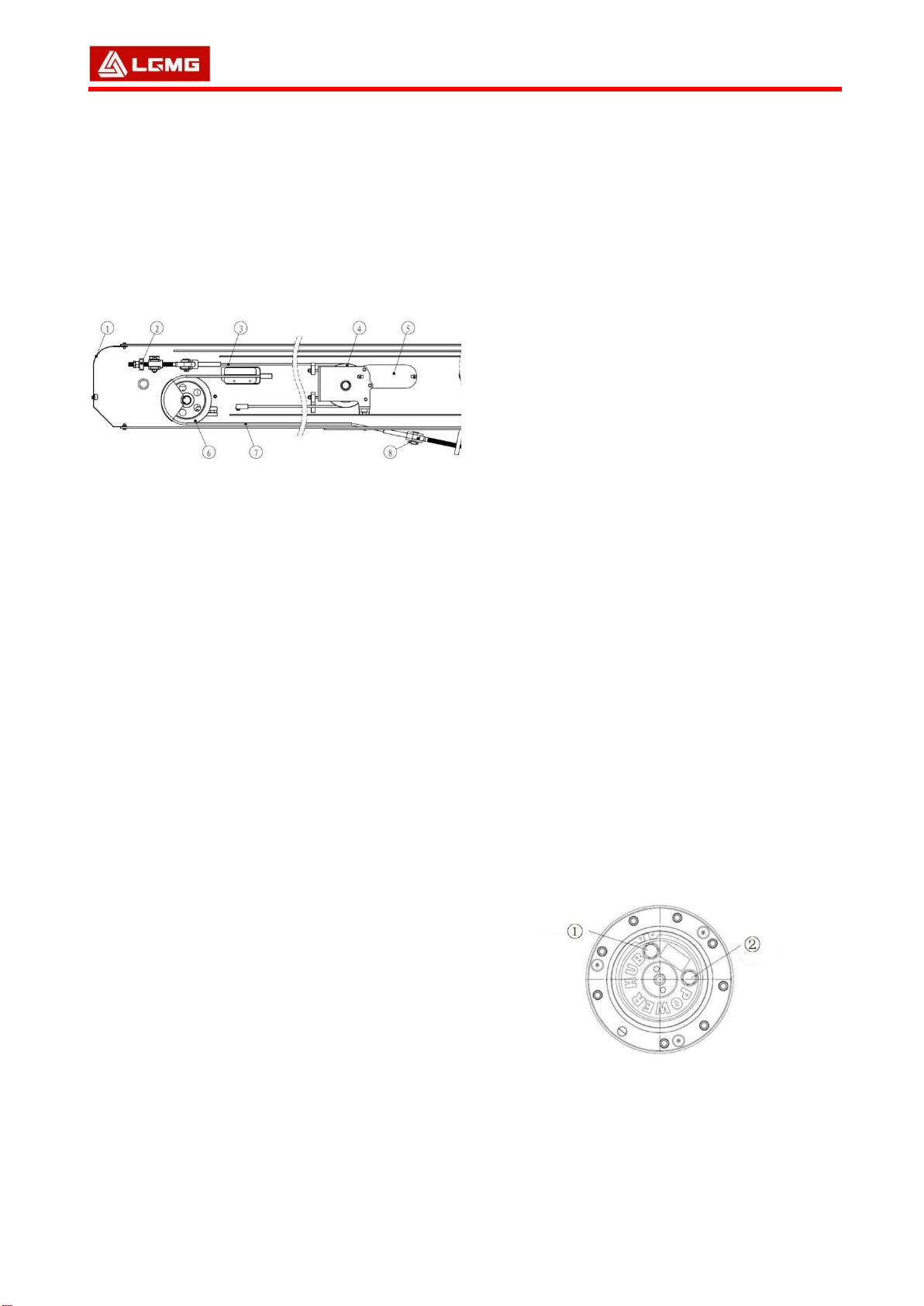

1.2 Inspecting the Pivoting

Support

1) The turntable shall rotate smoothly without

jamming, and meshing play between the

turntable bearing and the swing gearbox is

measured using a feeler gauge, which shall

be between 0.2mm and 0.3mm.

Measurement is conducted every 250 h or

quarterly.

Unscrew bolt 6 and locking nut 5

Turn adjusting bolt 4 to adjust the position

of the swing gearbox

Measure play between the turntable

bearing and the swing gearbox using a

feeler gauge

If the play ranges from 0.2mm to 0.3mm,

tighten lock nut 5 and bolt 6

Measure play between the turntable

bearing and the swing gearbox again to

verify the measurement

Tighten bolt 6, and torque to (595±5)N•m.

2) Check lubrication in the turntable bearing

and the swing gearbox at intervals of 100

hours. It is necessary for maintaining

performance and maintenance life to

lubricate the turntable bearing frequently.

Incorrect lubrication will cause damage to

components.As shown in Figure 11-1, find

the grease port 3 on the side of the bearing,

swing the turntable multiple times while

filling grease until grease overflows from

the upper and lower fixed surfaces of the

bearing. Lubricating grease must be:

Lubrication EP2 or equivalent.

3) Inspect the lubrication of the turntable

bearing and the swing gearbox, if

necessary, clean the gear surface, and

recoat with grease.

△

!Caution: In the case of an extremely dirty

working environment, increase the oil filling

frequency.

1.3 Inspecting the Boom

Wear Pad

1) Inspect the wear pad every 1,000 h or

yearly.

2) The wear pad is located on the housing

surface and inner wall of the boom to

reduce friction. It is necessary for safe

operation of the machine to maintain the

wear pad in good condition. Continuous

use of wear pads that are extremely worn

will result in damage to components and

unsafe operating conditions.

3) Extend the boom to check if the wear pad

loosens, if the wear pad loosens, torque the

securing bolt to: 28Nm. Inspect play

between the wear pad and the boom, if the

play is more than 1mm, arrange shims to