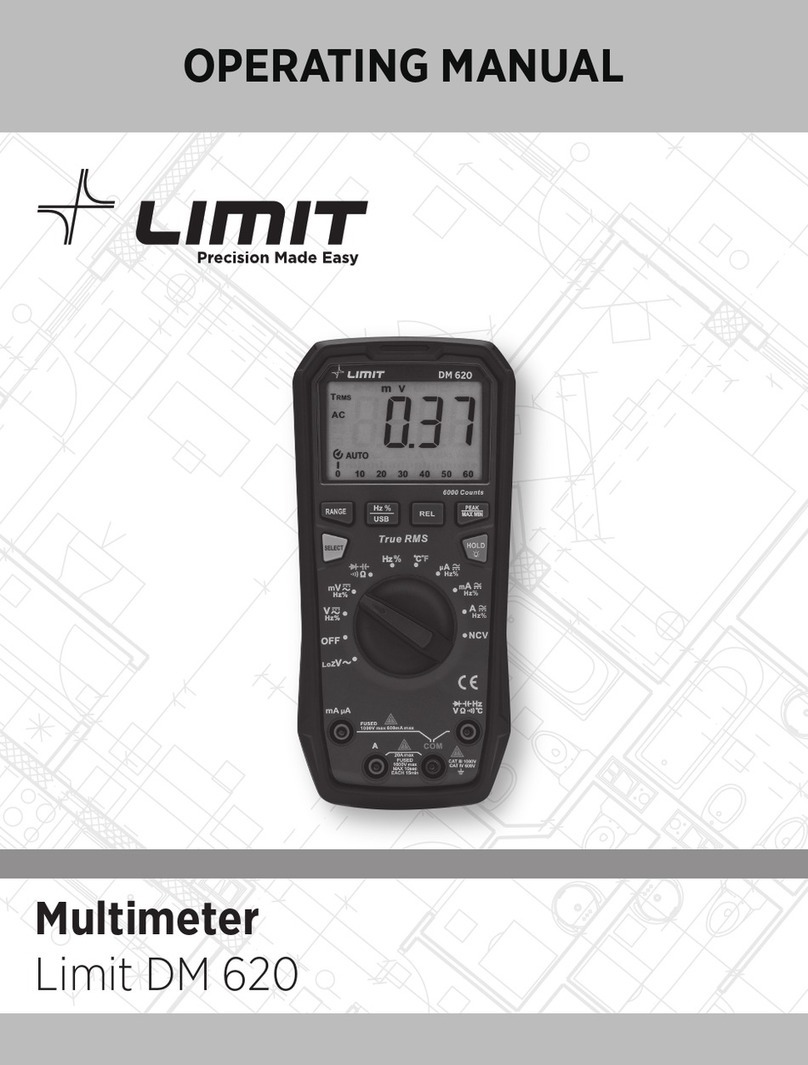

LIMIT 500 User manual

Operating manual

500

Digital Multimeter

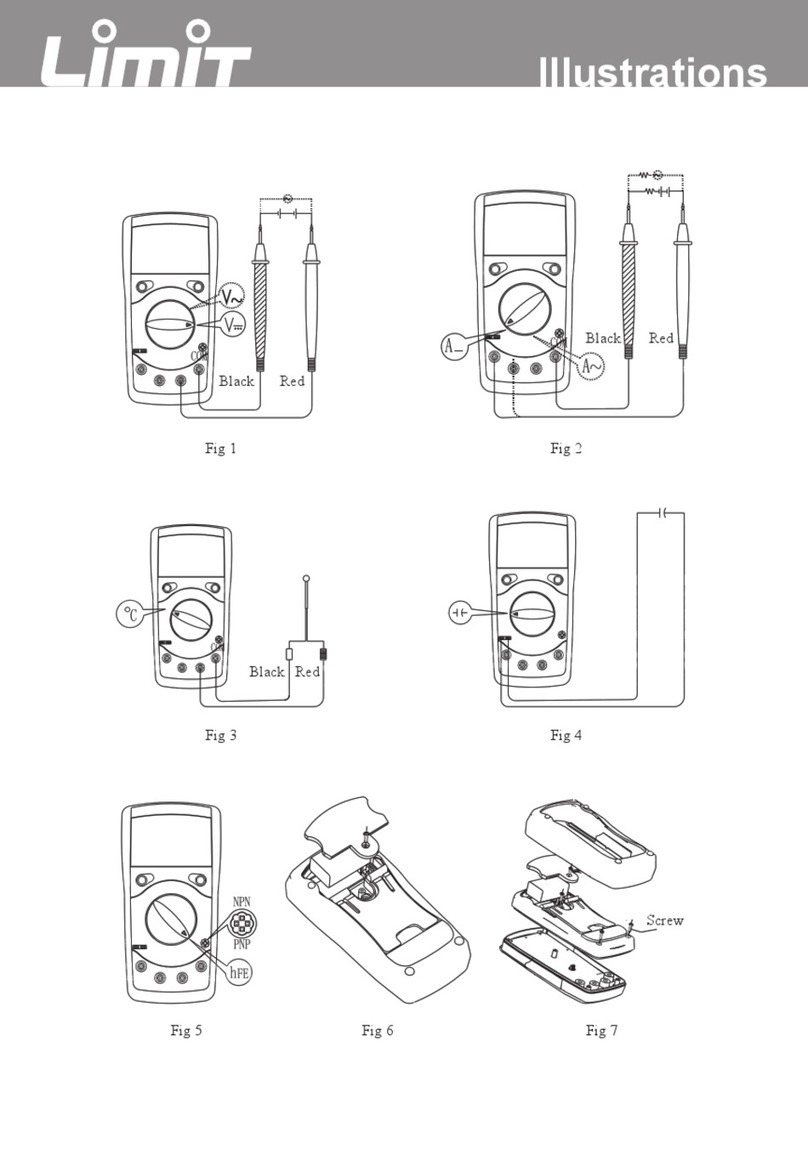

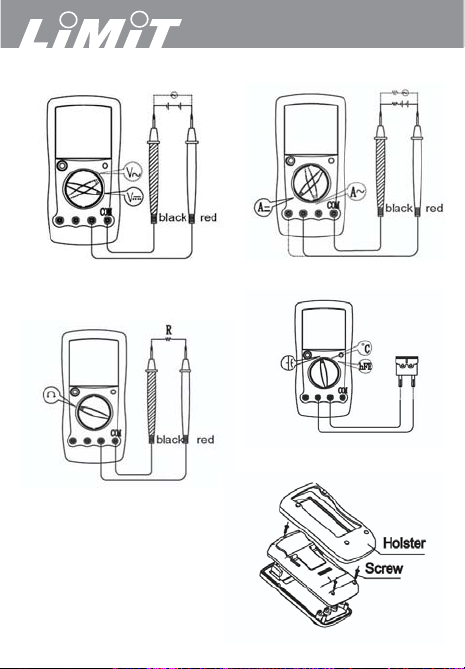

Fig 1. Voltage measurement

DC and AC

Fig 2. Current measurement AC

Fig 3. Diode test

Continuity test

Resistance

Fig 4. Replacing battery

Fig 5. Replacing battery

500

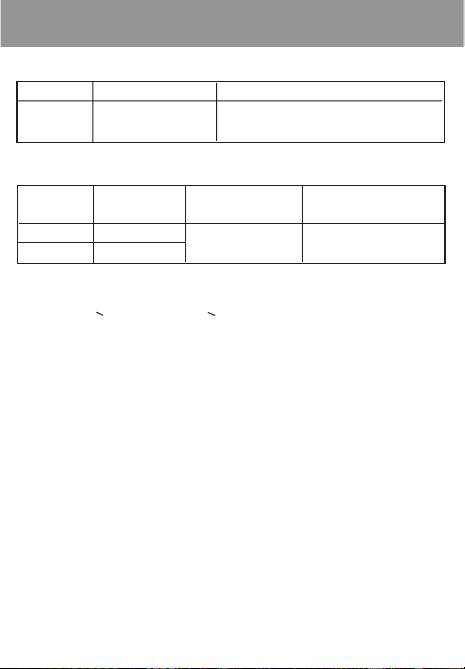

Illustrations & Tables

1

DC Voltage

Range Resolution Accuracy Overload

Protection

200mV 0.1mV 250V AC

2V 1mV ±(0,5%+1)

20V 10mV 1000V AC

200V 100mV

1000V 1V ±(0,8%+2)

AC Voltage

Range Resolution Accuracy Overload

Protection

2V 10mV

20V 10V ±(0.8%+3) 1000V AC

200V 100V

1000V 1V ±(1.2%+3)

DC Current

Range Resolution Accuracy Overload

Protection

2mA 1μA ±(0.8%+1) CE Version:Fuse 0.5A,

200mA 0.1mA ±(1.5%+1)

250V, fast type, 5x20mm

20mA 10mA ±(2%+5) Un-Fused

Diodes Test

Range Resolution Overload Protection

1mV 250V AC

AC Current

Range Resolution Accuracy Overload

Protection

2mA 1μA ±(1.0%+3)

CE Version: Fuse 0.5A,

200mA 0.1mA ±(1.8%+3)

250V, fast type, 5x20mm

20mA 10mA ±(3.0%+5)

Resistance

Range Resolution Accuracy Overload

Protection

200Ω0.1Ω±(0.8%+3) + Test Lead

2Ω1ΩShort Circuit Resistence 250V AC

20kΩ10Ω±(0.8%+1)

2kΩ1kΩ

20MΩ10MΩ±(1.0%+2)

Capacitance

Range Resolution Accuracy

2nF 1pF ±(4.0%+3)

200nF 0.1nF

100μF 0.1μF ±(5.0%+4) When it is > 40μF: the

obtained reading is only for reference

Temperature

Range Resolution Accuracy

-40°~0°C ± (3%+3)

°C 1°C 0~400°C ± (1%+3)

400~1000°C ± 2.5%

500

2

Transistor Test

Range Resolution Accuracy ±(a%reading + b digits)

hFE 1ß Vce≈3V Ibo≈10μA 1000ßMAX

Frequency (UT58C only)

Range Resolution Accuracy Overload

Protection

2kHz 1Hz

20Hz 10Hz ± (1.5%+5) 250V AC

Remarks

• 100mVrms < input amplitude < 30Vrms

3

Tabels

500

4

Language page

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Svenska . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-19

Norsk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-26

Dansk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27-34

Suomi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35-41

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42-50

Nederlands . . . . . . . . . . . . . . . . . . . . . . . . . . . .51-58

Français

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59-66

Italiano . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67-74

Español

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75-82

Português

. . . . . . . . . . . . . . . . . . . . . . . . . . . .83-90

Polska . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91-98

Eesti . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99-104

Latviski . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105-112

Lietuvi

Š

kai . . . . . . . . . . . . . . . . . . . . . . . .

113-120

PyÔÔÍËÌ . . . . . . . . . . . . . . . . . . . . . . . . . . . .121-127

Language Contents

5

English

Overview

General specification

Safety information

Voltage DC and AC

Current DC and AC

Resistance

Temperature

Diodes test

Continuity test

Capacitance

Transistor test

Frequency

Battery

Fuses

Contents

Overview

This Operating Manual covers information on safety and cautions.

Please read the relevant information carefully and observe all the

Warnings and Notes strictly.

Limit 500 are 3 1/2 digits instrument for professional use. Display

have large digits and also shows correct test leads terminals and

rotary switch position, makes this instrument easy to handle for the user.

General Specifications

Measuring range and accuracy see page 1-3.

•Fused Protection for VΩmA Input Terminal: 0,5A, 250V fast type,

5x20 mm.

•20A Terminal: Un-fused.

•Range: Manual ranging

•Maximum Display: Display: 1999 or 31/2 digits.

•Measurement Speed: Updates 2-3 times /second.

•Temperature: Operating: 0°C~40°C (32°F~104°F).

Storage: -10°C~50°C (14°F~122°F).

•

Battery Type: One piece of 9V Battery NEDA 1604 or 6F22 or 006P.

•Safety/Compliances: IEC61010 CAT II 1000V, CAT III 600 V over

voltage and double insulation standard.

•Certification:

Safety Information

This Meter complies with the standards IEC61010: in pollution

degree 2, over voltage category (CAT II 1000V, CAT III 600V) and

double insulation.

Warning

To avoid possible electric shock or personal injury, and to

avoid possible damage to the Meter or to the equipment under

test, adhere to the following rules:

6

500

7

English

•Before using the Meter inspect the case. Do not use the Meter if it

is damaged or the case (or part of the case) is removed. Look for

cracks or missing plastics. Pay attention to the insulation around

the connectors.

•Inspect the test leads for damages insulation or exposed metal.

Check the test leads for continuity.

•Do not apply more than the rated voltage, as marked on the

Meter, between the terminals or between any terminal and the

grounding.

•The rotary switch should be placed in the right position and no

any changeover of range shall be made during measurement is

conducted to prevent damage of the Meter.

•When the Meter working at an effective voltage over 60V in DC or

42V rms in AC, special care should be taken for there is danger of

electric shock.

•Do not use or store the Meter in an environment of high tempera-

ture; humidity, explosive, inflammable and strong magnetic fields.

The performance of the Meter may deteriorate after dampened.

•

When using the test leads, keep your fingers behind the finger guards.

•Disconnect circuit power and discharge all high-voltage capacitors

before testing resistance, continuity, diodes and current.

•Before measuring current, check the Meter fuses and turn off

power to circuit before connecting the Meter to the circuit.

•Replace the battery as soon as the battery indicator appears. Whit

to low battery, the Meter might produce false readings that can

lead to electric shock and personal injury.

Functional buttons

Hold • ON/OFF switch.

• ON/OFF for hold function.

Blue • H shows on the display when value is hold.

8

500

Voltage measurement DC and AC (see fig 1)

1. Insert the red test lead into the HzVΩterminal and the black test

lead into the COM terminal.

2. Set the rotary switch to an appropriate measurement position in

V--range for DC or V~ for AC. When the value is unknown always

start from the max range 1000 V.

3. Connect the test leads across with the object being measured.

The measured value shows on the display.

Note

•Displays 1 selected range is overload; it is required to select a

higher range in order to obtain a correct reading.

•

In each range, the Meter has an input impedance of approx.10MΩ.

This loading effect can cause measurement errors in high impe

dance circuits. If the circuit impedance is less than or equal to

10kΩ, the error is negligible (0.1% or less).

Current measurement DC and AC (see fig 2)

Warning

Never attempt an in-circuit current measurement where the voltage

between terminals and ground is greater than 250 V.

If the fuse burns out during measurement, the Meter may be dama-

ged or the operator himself may be hurt. Use proper terminals, func-

tion, and range for the measurement.

When the testing leads are connect-ed to the current terminals, do

not parallel them across any circuit.

Measuring time for current should be less than 10 sec and interval

between measurement should be at least 15 minutes.

To measure current, connect as follows:

1.

Turn off power to the circuit. Discharge all high-voltage capacitors.

2. Insert the red test lead into the A or mA terminal and the black

test lead into the COM terminal.

9

English

3. Set the rotary switch to an appropriate measurement position A

... range for DC or A~ for AC. When the value is unknown

always start from the max range 20 A.

4. Break the current path to be tested. Connect the red test lead to

the more positive side of the break and the black test lead to the

more negative side of the break.

5. Turn on power to the circuit. The measured value shows on the

display.

Note

•Displays 1 selected range is overload, it is required to select a

higher range in order to obtain a correct reading.

Resistance measurement

1. Insert the red test lead into the HzVΩterminal and the black test

lead into the COM terminal.

2. Set the rotary switch to an appropriate measurement position in

Ωrange.

3. Connect the test leads across with the object being measured.

The measured value shows on the display.

Note

•

The test leads can add 0.1Ωto 0.3Ωof error to resistance measure-

ment. To obtain precision readings in low-resistance measure-

ment, that is the range of 200Ω, short-circuit the input terminals

beforehand and record the reading obtained. This is the addi-

tional resistance from the test lead.

Temperature measurement (see fig 4)

1. Insert the multi socket into the mA and HzVΩterminals.

2. Set the rotary switch to the °C position.

3. Insert the temperature probe to the multi socket.

4. Place the temperature probe to the object being measured.

10

The measured value shows on the display.

Note

•The included point contact temperature probe can only be used

up to 230 °C.

•

The temperature function is type K. For measuring higher tempera-

tures other probes of type K can be used.

Diode test (see fig 3)

Use the diode test to check diodes, transistors, and other semicon-

ductor devices. The diode test sends a current through the semicon-

ductor junction, and then measures the voltage drop across the

junction. A good silicon junction drops between 0.5V and 0.8V.

To test a diode out of a circuit, connect as follows:

1. Insert the red test lead into the HzVΩterminal and the black test

lead into the COM terminal.

2. Set the rotary switch to diode position.

3. For forward voltage drop readings on any semiconductor compo-

nent, place the red test lead on the component’s anode and

place the black test lead on the component’s cathode.

The measured value shows on the display.

Continuity test (See fig 3)

To test for continuity, connect as follows:

1. Insert the red test lead into the HzVΩterminal and the black test

lead into the COM terminal.

2. Set the rotary switch to continuity position.

3. Connect the test leads across with the object being measured.

The buzzer sounds if the resistance of a circuit under test is less

than 70 Ω.

Capacitance measurement (See fig 4)

500

11

1. Insert the multi socket into the mA and HzVΩterminals.

2.

Set the rotary switch to an appropriate measurement position in F range.

3. Connect the capacitor to be tested into the multi socket. The

measured value shows on the display.

Note

•When 1 displays the capacitor is short-circuit or the selected

range is to low.

•

To minimize the measuring error caused by the distributed capaci-

tor, the testing lead should be short as possible.

Transistor test (See fig 4)

1. Insert the multi socket into the mA and HzVΩterminals.

2. Set the rotary switch to the hFE position.

3. Connect the NPN or PNP type transistor to be tested into the

multi socket. The measured value shows on the display.

Frequency

1. Insert the red test lead into the HzVΩterminal and the black test

lead into the COM terminal.

2. Set the rotary switch to an appropriate measurement position in

Hz range.

3. Connect the test leads across with the object being measured.

The measured value shows on the display.

Replacing the Battery (see figure 5)

1. Disconnect the connection between the testing leads and the cir-

cuit under test when battery indicator appears on the display.

2. Turn the Meter to OFF position.

3.

Remove the screw, and separate the case bottom from the case top.

4. Replace the battery with a new 9V battery (NEDA 1604 or 6F22

or 006P).

5. Rejoin the case bottom and case top, and reinstall the screw.

English

12

500

Replace the fuse (see figure 5)

1. Disconnect the connection between the testing leads and the cir-

cuit under test.

2. Turn the Meter to OFF position.

3.

Remove the screw and separate the case bottom from the case top.

4. Remove the fuse by gently prying one end loose, and then take

out the fuse from its bracket.

5. Replace only fuses with the identical type and specification as

follows. 0,5A 250V, fast type, 5x20mm.

6. Rejoin the case bottom and case top, and reinstall the screw.

Replacement of the fuses is seldom required. Burning of a fuse

always results from improper operation.

Table of contents

Other LIMIT Multimeter manuals