Page 4 - Copyright Llaza, S.A. - May 2011

As with any sun protection system, this product also seeks to achieve the greatest suitability in terms of two

intrinsic necessities:

■ Dimensions

■ Exposure to the elements (sun, wind, rain)

To address these factors, the materials chosen in the manufacture of this product have taken on vital im-

portance.

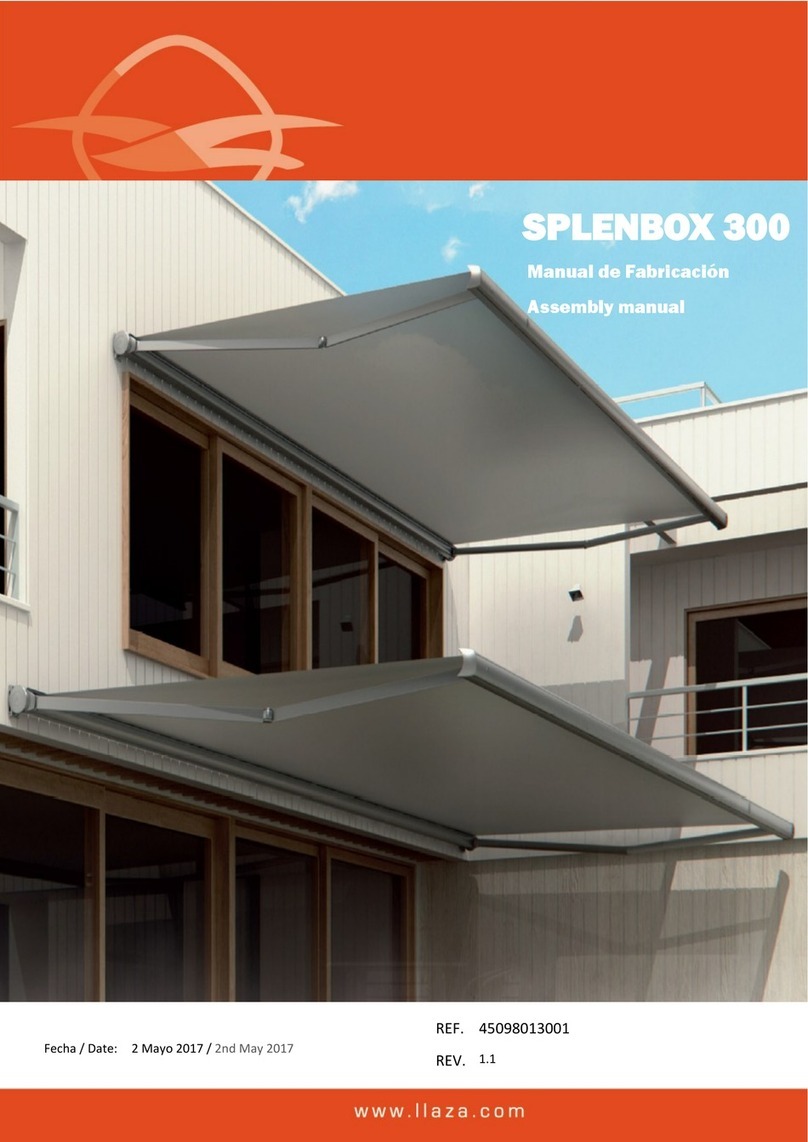

3. DESCRIPTION OF THE PARTS THAT MAKE UP THE MONOBOX-400

The square bar that suspends the system is made of extruded aluminium and can allow for projections of 3

metres or even more by placing a 35x35x2 steel pipe inside the bar. The system is suspended on extruded

aluminium brackets, with proven aerodynamic designs to offer unmatched strength and durability.

The rolling tube is anchored to two side brackets that form the ends of the upper cassette, where the fabric

is protected against potentially damaging weather conditions. Both brackets are attached by means of an

interior clamp that prevents the need to drill through the square bar, and to which the aluminium side covers

are also attached. This gives the assembly a novel and modern aesthetic look.

The rotational motion applied to the rolling tube when extending or retracting the fabric is activated by

means of a gearbox with a 1:5 ratio, which if required is accompanied by a tubular compensation spring.

The awning is then operated by either a manual crank or an electric motor positioned inside one end of the

rolling tube.

At the other end (and at the central support as well if the option to divide the width into two awnings has

been chosen), stainless steel ball bearings provide technically calculated support to ensure that the system

operates smoothly and perfectly.

The front profile that serves as a guiding element for opening and closing the system has been designed

with carefully calculated dimensions to be used with extended widths and to improve the aesthetics of the

system even further.

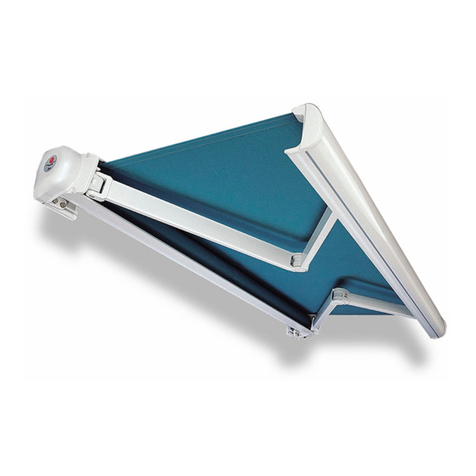

When the awning is extended, it is supported on a structure consisting of the articulated SPLENDOR-type

arms and the corresponding drop bar profile. This model of arm features bearings in the joint, as well as an

internal tensioning system inside the profiles that uses an elongation mechanism, with transmission of the

longitudinal difference by means of a patented flexible tape system. This ensures that the product performs

well above the applicable European EN 13561 standard.

Acrylic or high-tech fabric offers superior sun protection, and is ex-

tended and retracted by rolling onto a steel or aluminium tube. The

MATIC system that attaches the articulated arms to the bar, and

which is made of aluminium, stainless steel, and special bolts, fea-

tures a piston-type action inside, which prevents variability in the incli-

nation of the arm when the awning is fully extended. When retracted,

the cam system returns the arm to a position with 0° inclination. This

allows the movement of the front or drop bar profile with the texpro

system (both made of extruded aluminium) to always occur at this an-

gle.

MONOBOX-400