Setting mode - selected after pressing the “+”

or “-” button. The display shows the set

temperature. Indications are shown in °C. The

display flashes and after a while it returns to

the measured temperature (operation mode).

Work time setting mode (Pro.) - started after

holding down the "ON / OFF" button. The

display shows the working time (counting from

the moment of switching on), after which the

thermostat switches off automatically. The

indication are shown in hours.

Display brightness setting mode (d.br.) -

activated after holding down the "ON / OFF"

button. The display shows the currently set

brightness. Reaching the setting limit is

signaled by flickering.

The following modes are available only after

entering the access code.

When starting up the controller (displayed controller

name, software version and settings) press and hold

the "-" and "+" buttons. After the display shows "- - -"

the buttons can be released and the code entered.

Confirm the code with the "ON / OFF" button.

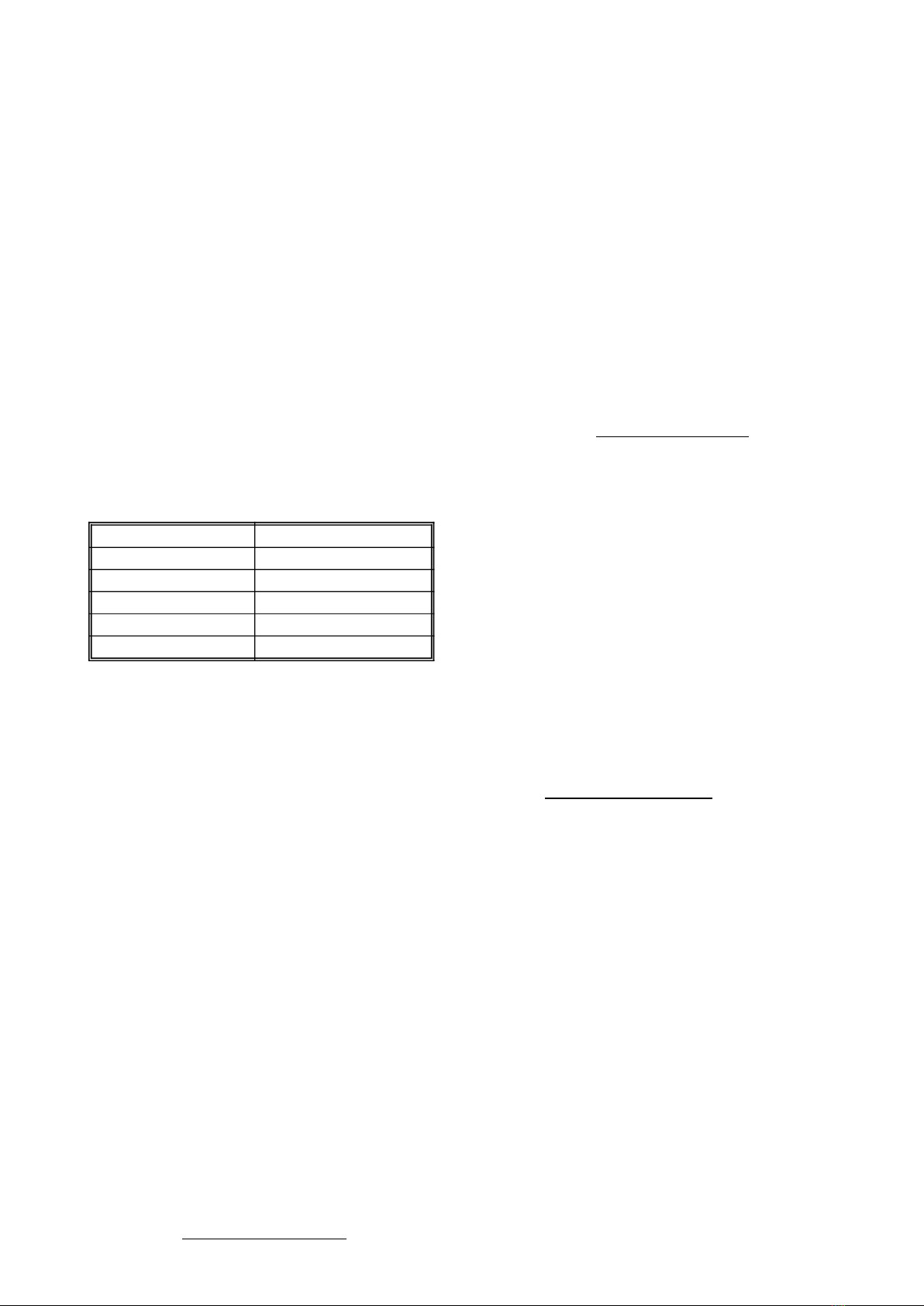

CODE ACCESS LEVEL

random L-0

157 L-1

314 L-2

628 L-3

942 L-4

Working time setting mode (L-0)

Display brightness setting mode (L-0)

Calibration mode (L-1)

Preheating time setting mode (L-2)

Preheating temperature setting mode (L-3)

Preset temperature limit setting mode (L-4)

Calibration mode (CAL.) L-1 - activated after holding

down the "ON / OFF" button. The display shows the

calibrated value of temperature. Display unit: °C.

Preheating time setting mode (P.tI.) L-2 - activated

after holding down the "ON / OFF" button. The display

shows the preheating time, counting from the moment

of switching on, during which the controller performs

initial heating and maintains the initial heating

temperature programmed by the manufacturer. The

indication "OFF" means the preheating function is not

active.

Display unit: minutes. When pre-heating is activated,

the controller displays "HC2" during startup.

Preheating temperature setting mode (P.tE.) L-3 -

activated after long pressing the "ON / OFF" button. The

display shows the value of the preset preheating

temperature. Display unit: °C.

Preset temperature limit setting mode

(L.t.h.) L-4 - activated after long pressing the

"ON / OFF" button. The display shows the

maximum value of the set temperature that

can be set. Display unit: °C.

4 – minus “-” button

Operation mode - Pressing the button decreases the preset

temperature value. During preheating, the possibility of

changing the preset temperature setting is blocked.

Working time setting mode - pressing the button decreases

the time after which the thermostat is automatically turned off.

Display brightness setting mode - pressing the button

decreases the display brightness.

Calibration mode - pressing the button decreases the value of

the indicated (calibrated) temperature.

Preheating time setting mode - pressing the button reduces

the time after which the thermostat automatically switches from

the preliminary heating phase to the work heating phase.

Preheating temperature setting mode - pressing the button

decreases the value of the preset temperature that is

maintained during preliminary heating.

Preset temperature limit setting mode - pressing the button

decreases the value of the maximum preset temperature that

can be set.

5 – p lus „+” button

Operation mode - Pressing the button increases the preset

temperature value. During preheating, the possibility of

changing the preset temperature setting is blocked.

Working time setting mode - pressing the button increases

the time after which the thermostat is automatically turned off.

Display brightness setting mode - pressing the button

increases the display brightness.

Calibration mode - pressing the button increases the value of

the indicated (calibrated) temperature.

Preheating time setting mode - pressing the button increases

the time after which the thermostat automatically switches from

the preliminary heating phase to the work heating phase.

Preheating temperature setting mode - pressing the button

increases the value of the preset temperature that is

maintained during preliminary heating.

Preset temperature limit setting mode - pressing the button

increases the value of the maximum preset temperature that

can be set.

6 – „ON/OFF” button

Pressing the button alternately turns the controller ON and

OFF. In the OFF state, the controller behaves like a

thermometer. In the ON state, the controller enables and

disables the heater control relay to maintain the

temperature set by the user.

Longer pressing and holding the button and then releasing

the button activates the working time setting mode,

indicated by the displayed message (Pro.). In this mode,

using the "+" and "-" buttons adjust the time after which the

controller will automatically turn off. To exit from this mode

and to confirm settings short press the "ON / OFF" button.

Press and hold and then release the button to enter the

display brightness setting mode – which is indicated by

(d.br.) message. In this mode, use the "+" and "-" buttons,

to set the brightness of the display. To exit this mode and to

confirmo settings short press the "ON / OFF" button.

Press and hold and then release the button to enter the

calibration mode, which is indicated by the displayed

message (CAL.). In this mode, use the "+" and "-" buttons,

to adjust the displayed temperature value. To exit this mode

and to confirm the calibration settings short press the "ON /

OFF" button. Note - the controller is factory calibrated.

Press and hold and then release the button to activate the pre-