TABLE OF CONTENTS

Form # 169089 3Model Year - 2010

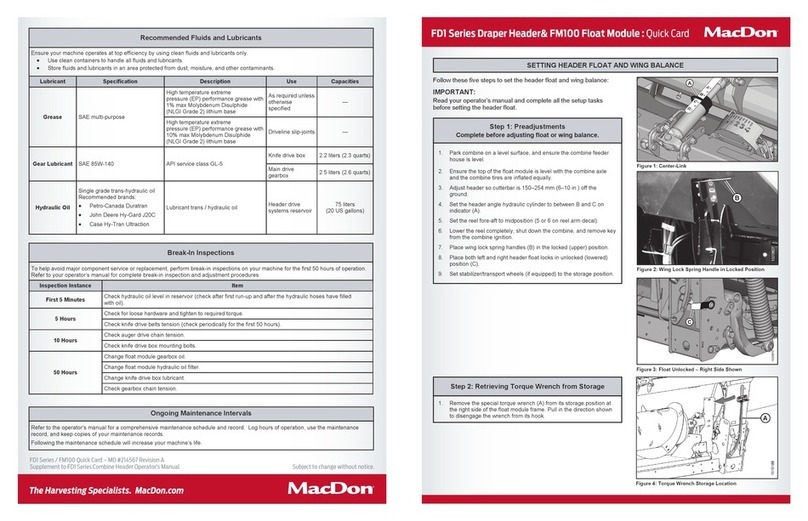

7.3.1 Recommended Torques ................................................................................................................... 36

7.3.2 Recommended Lubricants................................................................................................................ 38

7.3.3 Conversion Chart.............................................................................................................................. 39

7.4 HEADER LIFT CYLINDER LOCKS........................................................................................................ 40

7.5 DRIVE SHIELDS .................................................................................................................................... 40

7.6 CUTTERBAR DOORS............................................................................................................................ 40

7.7 LUBRICATION........................................................................................................................................ 41

7.7.1 Procedure ......................................................................................................................................... 41

7.7.2 Lubrication Points ............................................................................................................................. 41

I. 13 FT Header...................................................................................................................................... 42

II. 16 FT Header...................................................................................................................................... 44

III. 16 FT Header – Grass Seed Header.................................................................................................. 46

7.7.3 Sealed Bearing Installation............................................................................................................... 47

7.8 CUTTERBAR.......................................................................................................................................... 48

7.8.1 Skid Plates and Rock Guards........................................................................................................... 48

7.8.2 Cutter Bar Lubrication....................................................................................................................... 50

7.8.3 Disc Maintenance ............................................................................................................................. 52

7.8.4 Cutter Blades .................................................................................................................................... 55

7.8.5 Accelerators...................................................................................................................................... 58

7.8.6 Deflectors.......................................................................................................................................... 59

7.8.7 Tall Crop Feed Plates....................................................................................................................... 63

7.9 HEADER DRIVE..................................................................................................................................... 65

7.9.1 Hydraulic Motor................................................................................................................................. 65

7.9.2 Converging Drum Motors – Grass Seed Header ............................................................................. 65

7.9.3 Conditioner Drive Belt....................................................................................................................... 66

7.9.4 Conditioner Drive Belt Idler............................................................................................................... 70

7.9.5 Lifting Roll Drive Belt ........................................................................................................................ 71

7.9.6 Lifting Roll Belt Idler.......................................................................................................................... 72

7.9.7 Lifting Roll Idler Bearing ................................................................................................................... 72

7.9.8 Hourglass Deflector Drive Belts – 16 Ft Only................................................................................... 73

7.9.9 Bevel Gearbox .................................................................................................................................. 75

7.9.10 Conditioner Gearbox – 13 Foot ........................................................................................................ 81

7.9.11 Conditioner Gearbox – 16 Foot ........................................................................................................ 85

7.9.12 Gearbox Speed Sensor .................................................................................................................... 89

7.10 HYDRAULICS......................................................................................................................................... 90

7.10.1 Hoses And Lines............................................................................................................................... 90

7.11 ELECTRICAL.......................................................................................................................................... 90

7.12 MAINTENANCE SCHEDULE................................................................................................................. 91

7.12.1 Break-In Inspection........................................................................................................................... 91

7.12.2 Interval Maintenance ........................................................................................................................ 92

7.12.3 Maintenance Record......................................................................................................................... 93

8TROUBLESHOOTING.................................................................................................................................... 94

8.1 MOWER PERFORMANCE..................................................................................................................... 94

8.2 MECHANICAL ........................................................................................................................................ 96

9OPTIONS AND ATTACHMENTS ................................................................................................................... 98

9.1 GAUGE ROLLER KIT............................................................................................................................. 98

9.2 SKID SHOE KIT...................................................................................................................................... 98

9.3 SKID PLATE LIFT KIT ............................................................................................................................ 98

9.4 TALL CROP DIVIDER KIT...................................................................................................................... 98

9.5 CUTTERBAR REPAIR TOOL KIT.......................................................................................................... 98

9.6 DOUBLE WINDROW ATTACHMENT.................................................................................................... 98

9.7 WINDROW FORMING RODS................................................................................................................ 99

9.8 11 DEGREE BEVEL UP CUTTERBLADES ........................................................................................... 99

9.9 TALL CROP TRANSITION SHIELD....................................................................................................... 99

10 UNLOADING AND ASSEMBLY................................................................................................................... 100

INDEX .................................................................................................................................................................... 101