215026 viii Revision A

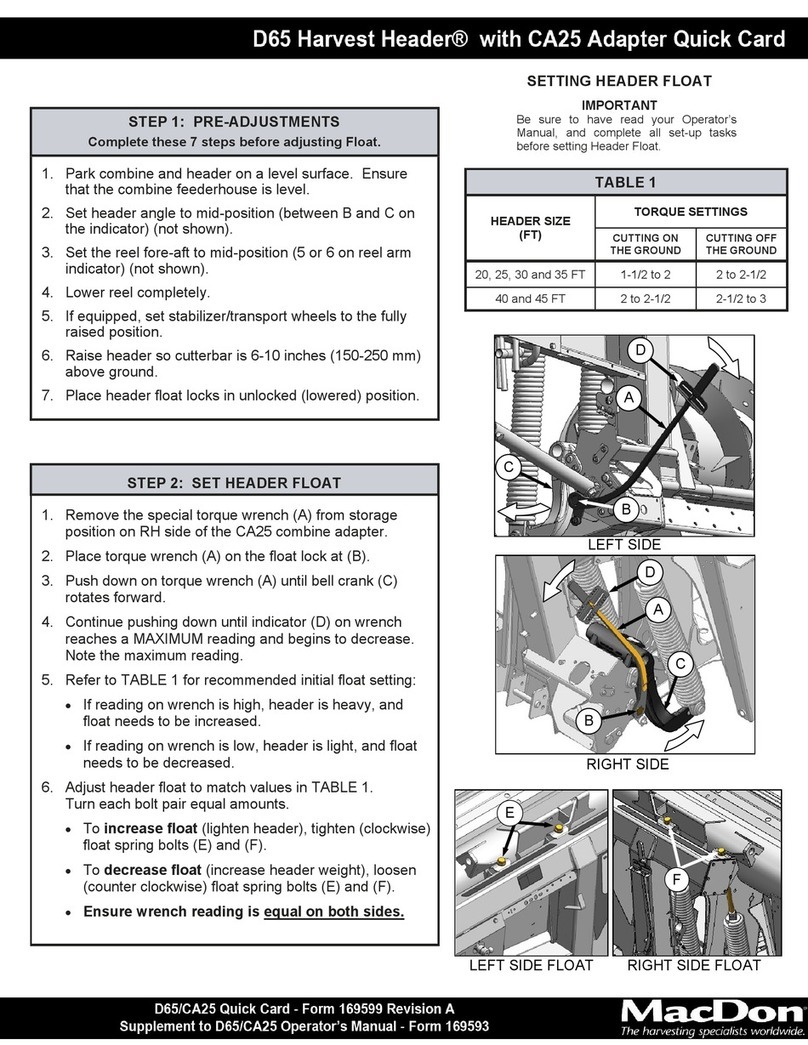

3.7.3 Header Float ............................................................................................................................... 52

3.7.4 Ground Speed ............................................................................................................................. 53

3.8 Conditioner ......................................................................................................................................... 54

3.8.1 Roll Gap ..................................................................................................................................... 54

Adjusting Roll Gap –Steel Rolls ..................................................................................................... 54

Adjusting Roll Gap –Polyurethane Rolls.......................................................................................... 55

3.8.2 Roll Tension ................................................................................................................................ 56

Adjusting Roll Tension ................................................................................................................. 56

3.8.3 Roll Timing.................................................................................................................................. 57

Checking Roll Timing ................................................................................................................... 57

Adjusting Roll Timing................................................................................................................... 57

3.8.4 Forming Shields –Roll Conditioner.................................................................................................. 61

Positioning Forming Shield Side Deflectors –Roll Conditioner............................................................. 61

Positioning Rear Baffle –Roll Conditioner ....................................................................................... 62

3.9 Cutterbar Deflectors ............................................................................................................................. 65

3.9.1 Removing Cutterbar Deflectors....................................................................................................... 65

3.9.2 Installing Cutterbar Deflectors ........................................................................................................ 66

3.10 Haying Tips ........................................................................................................................................ 67

3.10.1 Curing ...................................................................................................................................... 67

3.10.2 Topsoil Moisture ........................................................................................................................ 67

3.10.3 Weather and Topography ............................................................................................................ 67

3.10.4 Windrow Characteristics.............................................................................................................. 68

3.10.5 Driving on Windrow.................................................................................................................... 68

3.10.6 Using Chemical Drying Agents ...................................................................................................... 68

3.11 Transporting the Header ...................................................................................................................... 69

Chapter 4: Maintenance and Servicing.................................................................................................... 71

4.1 Daily Start-Up Check ............................................................................................................................. 71

4.2 Preparing Machine for Servicing.............................................................................................................. 73

4.3 Recommended Safety Procedures ........................................................................................................... 74

4.4 Maintenance Requirements ................................................................................................................... 76

4.4.1 Maintenance Schedule/Record....................................................................................................... 76

4.4.2 Break-In Inspections ..................................................................................................................... 78

4.4.3 Preseason Servicing...................................................................................................................... 78

4.4.4 End-of-Season Servicing ................................................................................................................ 79

4.5 Lubrication .......................................................................................................................................... 80

4.5.1 Greasing Procedure ...................................................................................................................... 80

4.5.2 Lubrication Locations.................................................................................................................... 81

4.6 Cutterbar System.................................................................................................................................. 83

4.6.1 Lubricating Cutterbar.................................................................................................................... 83

Checking and Adding Lubricant in Cutterbar .................................................................................... 83

Draining the Cutterbar................................................................................................................. 86

Filling Cutterbar with Lubricant ..................................................................................................... 87

4.6.2 Cutterbar Discs ............................................................................................................................ 88

Inspecting Cutterbar Discs ............................................................................................................ 89

TABLE OF CONTENTS