Eurosystem / Profi-LON

IV D1 E101BA1-GB09

3.5.2 Brake Test –Single Wheel Test with Remote Control..............................................3.13

3.6 Noise Investigation (Optional)...................................................................................................3.14

3.6.1 Manual Operation without Remote Control...............................................................3.14

3.6.2 Manual Operation with Remote Control....................................................................3.15

3.7 4-Wheel Drive (Optional) ..........................................................................................................3.16

3.7.1 Brake Test 4-Wheel Drive .........................................................................................3.16

3.7.2 ASR / ASD Test.........................................................................................................3.19

4Eurosystem Operation (PC Program)...................................................................4.1

4.1 Introduction .................................................................................................................................4.1

4.1.1 Start Eurosystem.........................................................................................................4.1

4.1.2 Main Menu...................................................................................................................4.2

4.1.3 Screen Elements.........................................................................................................4.2

4.1.4 Keyboard Usage..........................................................................................................4.4

4.1.5 Exit Program................................................................................................................4.5

4.2 Automatic Test Procedure ..........................................................................................................4.6

4.2.1 General Information.....................................................................................................4.6

4.2.2 Side-Slip Test..............................................................................................................4.7

4.2.3 Shock Absorber Test / Suspension Tester..................................................................4.8

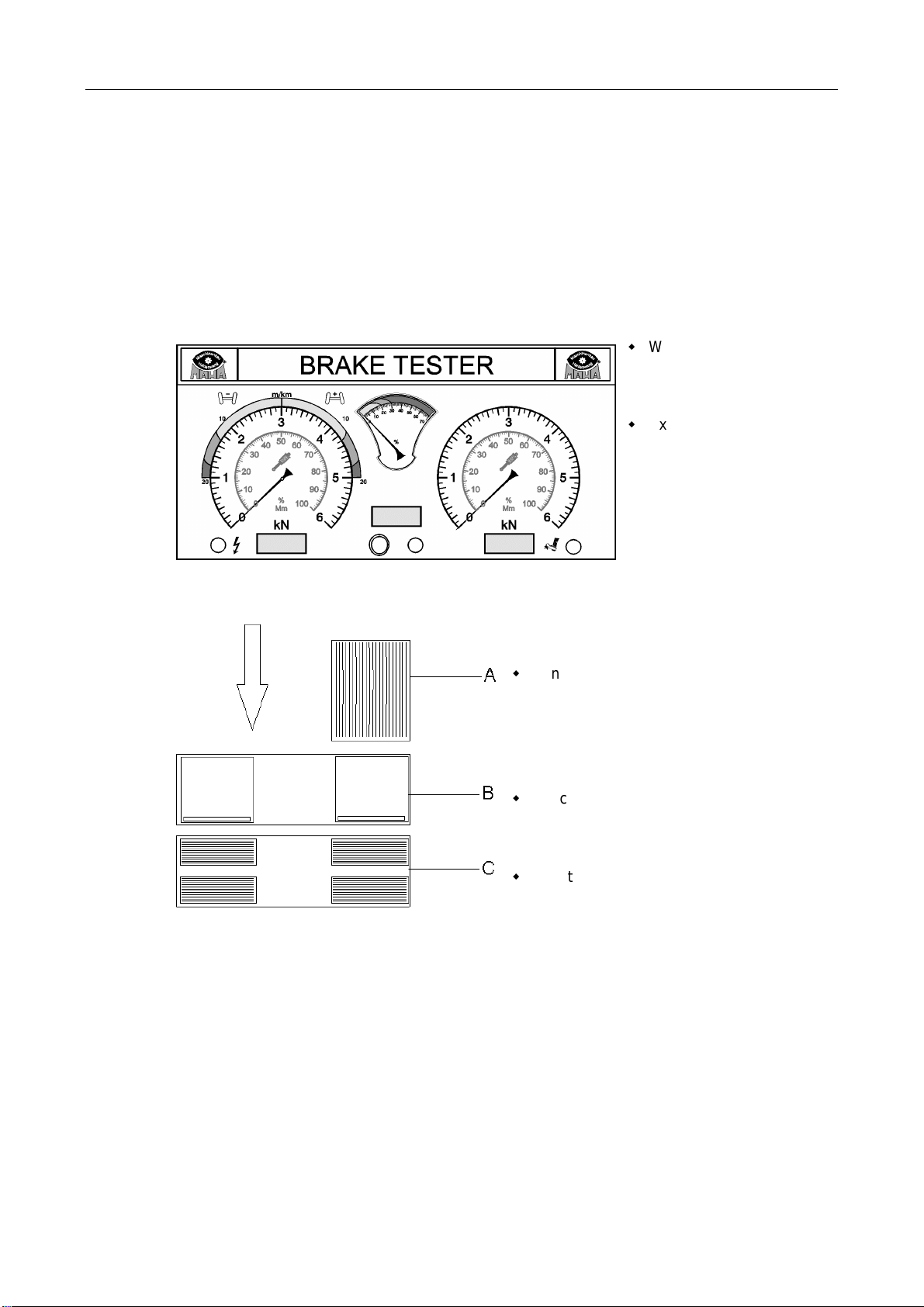

4.2.4 Brake Test...................................................................................................................4.9

4.2.5 Visual Defects............................................................................................................4.12

4.2.6 Storage of the Test Values........................................................................................4.14

4.2.7 Prepare New Test......................................................................................................4.15

4.3 Customer Administration...........................................................................................................4.16

4.3.1 Enter New Customer and Store ................................................................................4.16

4.3.2 Allocate Customer to Vehicle ....................................................................................4.17

4.3.3 Taking Customers into the Queue.............................................................................4.18

4.3.4 Display (Load) Customer Data..................................................................................4.19

4.3.5 Change, Expand, Update Customer Data.................................................................4.20

4.3.6 Delete Customer Data...............................................................................................4.20

4.4 Re-Display of Measurements ...................................................................................................4.21

4.4.1 Brake Test.................................................................................................................4.23

4.4.2 Shock Absorber Test.................................................................................................4.26

4.4.3 Side-Slip Test............................................................................................................4.27

4.4.4 Speedometer Test.....................................................................................................4.27

4.4.5 Odometer Test...........................................................................................................4.27

4.4.6 Toe Angle Difference.................................................................................................4.28

4.4.7 4-Gas Test.................................................................................................................4.28

4.4.8 Diesel Emission Test.................................................................................................4.28

4.4.9 Headlight Tester........................................................................................................4.29

4.4.10 Visual Defects............................................................................................................4.29

4.4.11 Brake Fluid Test ........................................................................................................4.29

4.4.12 Noise Level Test........................................................................................................4.30

4.4.13 Wheel Alignment .......................................................................................................4.30

4.4.14 Performance Test......................................................................................................4.30

4.5 Vehicle Administration ..............................................................................................................4.31

4.5.1 Enter New Vehicle and Store ....................................................................................4.32

4.5.2 Display (Load) Vehicle Data......................................................................................4.34

4.5.3 Change, Expand, Update Vehicle Data ....................................................................4.34

4.5.4 Delete Vehicle ...........................................................................................................4.35

4.6 Administration / Office...............................................................................................................4.36

4.6.1 Database Administration ...........................................................................................4.36

4.6.2 Printer Menu..............................................................................................................4.40

4.6.3 Test Equipment .........................................................................................................4.41

4.6.4 AU-Quality Control (Emission Testing)......................................................................4.43

4.7 Miscellaneous ...........................................................................................................................4.44

4.7.1 Display LON Variables/Print......................................................................................4.44

4.7.2 Settings......................................................................................................................4.45

4.7.3 Password Menu.........................................................................................................4.52