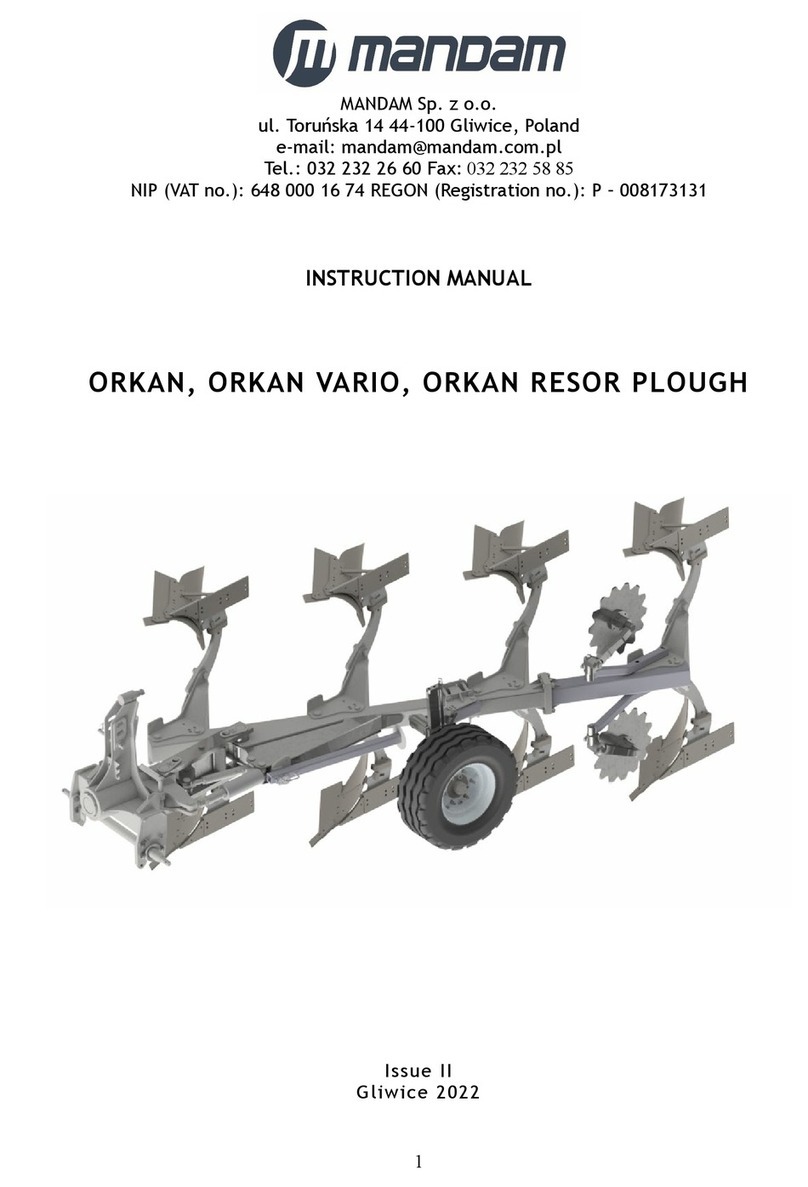

Mandam ORKAN VARIO Series User manual

P.P.H. MANDAM Sp. z o.o.

44-100 Gliwice ul.Toruńska 2

e-mail [email protected]

Tel.: 032 232 26 60 Fax: 032 232 58 85

NIP: 648 000 16 74 REGON: P – 008173131

INSTRUCTION MANUAL

ORKAN VARIO PLOUGH

1st Edition

Gliwice 2017

1

ORKAN VARIO PLOUGH

Type/model:…..........................................................

Year of manufacture:............................................

Serial no.:…...............................................................

EC DECLARATION OF CONFORMITY

FOR THE MACHINERY

In accordance with the Ordinance of the Minister of the Economy dated 21 October 2008 (Journal of

Laws No. 199, item 1228)

and European Union Directive No. 2006/42/EC dated 17 May 2006

Przedsiębiorstwo Produkcyjno-Handlowe „MANDAM” Sp. z o.o.

ul. Toruńska 2

44-100 Gliwice

hereby declares, taking full responsibility that the following machinery:

to which this declaration refers meets the following requirements:

The Ordinance of the Ministry of the Economy dated 21 October 2008 on the

essential requirements for machinery (Journal of Laws No. 199, item 1228)

and European Union Directive No. 2006/42/EC dated 17 May 2006

Persons responsible for the machinery’s technical documentation: Jarosław Kudlek, Łukasz Jakus

ul. Toruńska 2, 44-100 Gliwice

The following standards were also used for the purpose of conformity assessment:

PN-EN ISO 13857:2010,

PN-EN ISO 4254-1:2009,

PN-EN ISO 12100-1:2005/A1:2009

PN-EN ISO 12100-2:2005/A1:2009

PN-EN 982+A1:2008

The present EC declaration of conformity will no longer be valid if the machinery is modi-

ed or rebuilt without the manufacturer’s consent.

Gliwice 14.12.2015 ………………………………………

Place and date of issue First and last name, position held

and signature of the person authorized

2

Contents

1 Introduction..........................................................................................4

1.1.Safety markings.................................................................................5

2 General information.................................................................................7

2.1.Construction of the ORKAN VARIO plough..................................................7

2.2.Intended use of the ORKAN VARIO plough..................................................8

3 General safety precautions.......................................................................10

3.1.Hitching and unhitching to a tractor.......................................................11

3.2.Tyres............................................................................................11

3.3.Hydraulic system..............................................................................12

3.4.Transporting on public roads................................................................12

3.5.Description of residual risk..................................................................14

3.6.Residual risk assessment.....................................................................14

4 Plough and tractor settings.......................................................................15

4.1.Preparing the plough.........................................................................17

4.2.Selection of the hitching bar................................................................17

4.3.Hitching the plough to the tractor.........................................................17

4.4.Adjustment of the hitching bar height....................................................18

4.5.Adjustment of the furrow width............................................................18

4.6.Adjusting the rst ridge......................................................................19

4.7.Levelling........................................................................................20

4.8.Adjusting the furrow depth.................................................................20

4.9.Rolling coulter.................................................................................21

4.10.Plough share.................................................................................22

4.11.Skim coulter..................................................................................22

4.12.Soil compactor arm.........................................................................23

4.13.Assembly and dismantling of the end pair of plough bodies.........................24

5 Operating the ORKAN VARIO plough.............................................................24

5.1.Lubrication.....................................................................................24

5.2.Worn out components........................................................................25

5.3.Securing bolts..................................................................................26

5.4.Gauge wheel...................................................................................26

5.5.Hydraulic system..............................................................................27

6 Storing the ORKAN VARIO plough................................................................28

7 Dismantling and disposal..........................................................................28

8 Technical characteristics..........................................................................28

9 General rules governing the warranty procedure.............................................29

WARRANTY CARD......................................................................................30

3

1 Introduction

We sincerely congratulate you on purchasing the ORKAN VARIO plough.

This instruction manual provides information on the hazards that may occur

during use, plough operation, technical data and the most important indications and

recommendations, the knowledge and use of which is a prerequisite for proper operation.

Keep this instruction manual for future reference. If you do not understand any provisions

of this instruction manual, please contact the manufacturer.

Recommendations that are important for safety reasons are marked with the following

sign:

Machine identication

Identication data concerning the plough are to be found on the nameplates located

on the support frame, which includes a CE marking, and basic information about the

manufacturer and the machinery:

The plough’s warranty is valid for 24 months from the date of sale.

The warranty card is attached hereto and placed on the last page of this instruction manual.

The warranty card constitutes an integral part of the machinery.

Always provide the serial number when submitting inquiries for spare parts.

Spare parts information:

• website: http://mandam.com.pl/parts/

• phone: +48 668 662 289

• e-mail: [email protected]

4

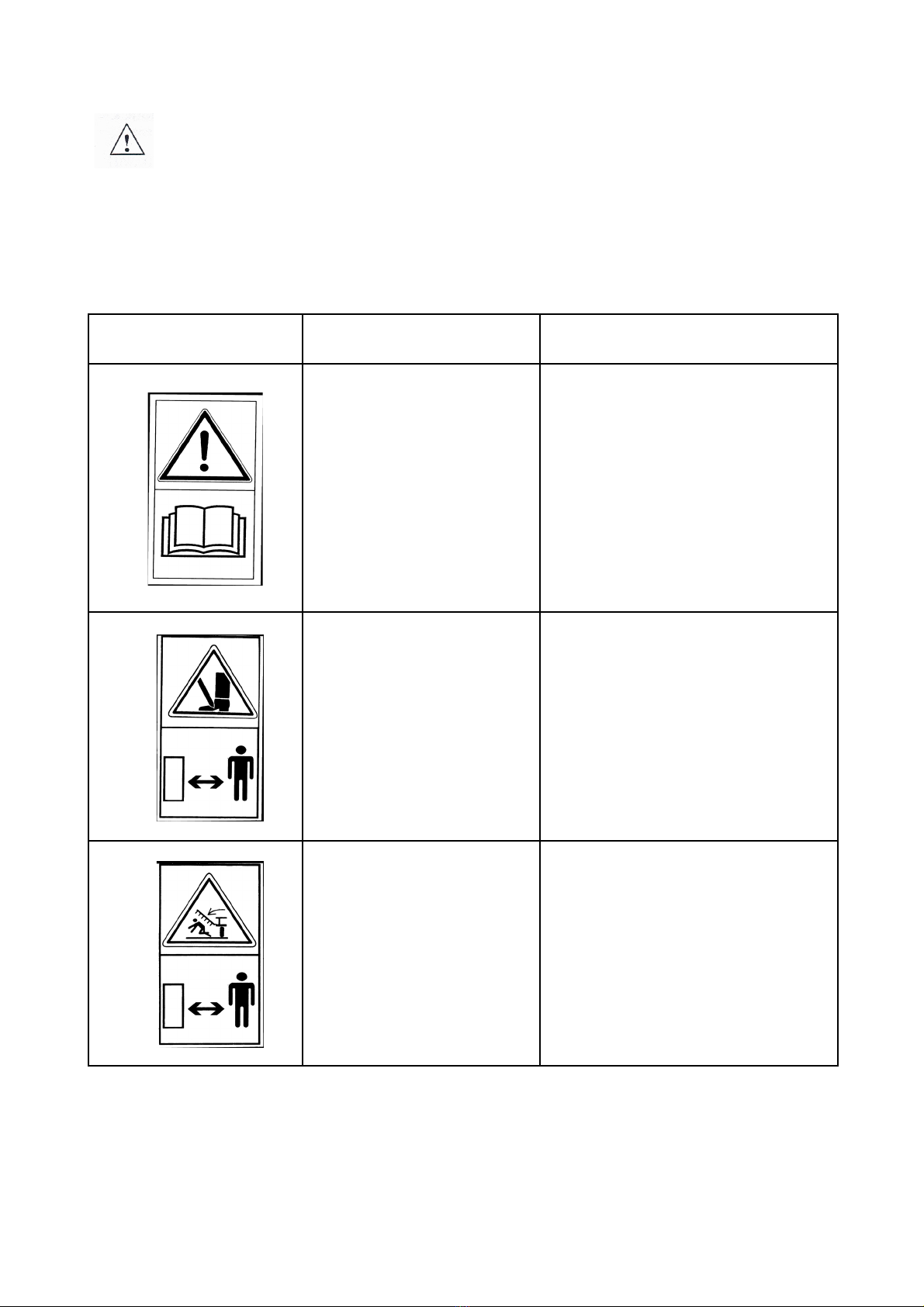

1.1. Safety markings

WARNING! When using this piece of machinery, special care must be taken in

areas marked with special information and warning signs (yellow stickers).

Below are the characters and inscriptions placed on this piece of machinery. Safety signs

and inscriptions should be protected from loss and illegibility. Signs and inscriptions that

become lost or illegible should be replaced by new ones.

Table 1. Information and safety markings.

5

Safety marking Meaning of the safety

marking

Place located on the piece of ma-

chinery

Read the instruction

manual before use.

Frame near xing of the upper

connector

Danger of toes or feet

being crushed.

Frame near xing of the upper

connector

Keep a safe distance from

holding parts and pieces of

machinery in motion The rear of the frame

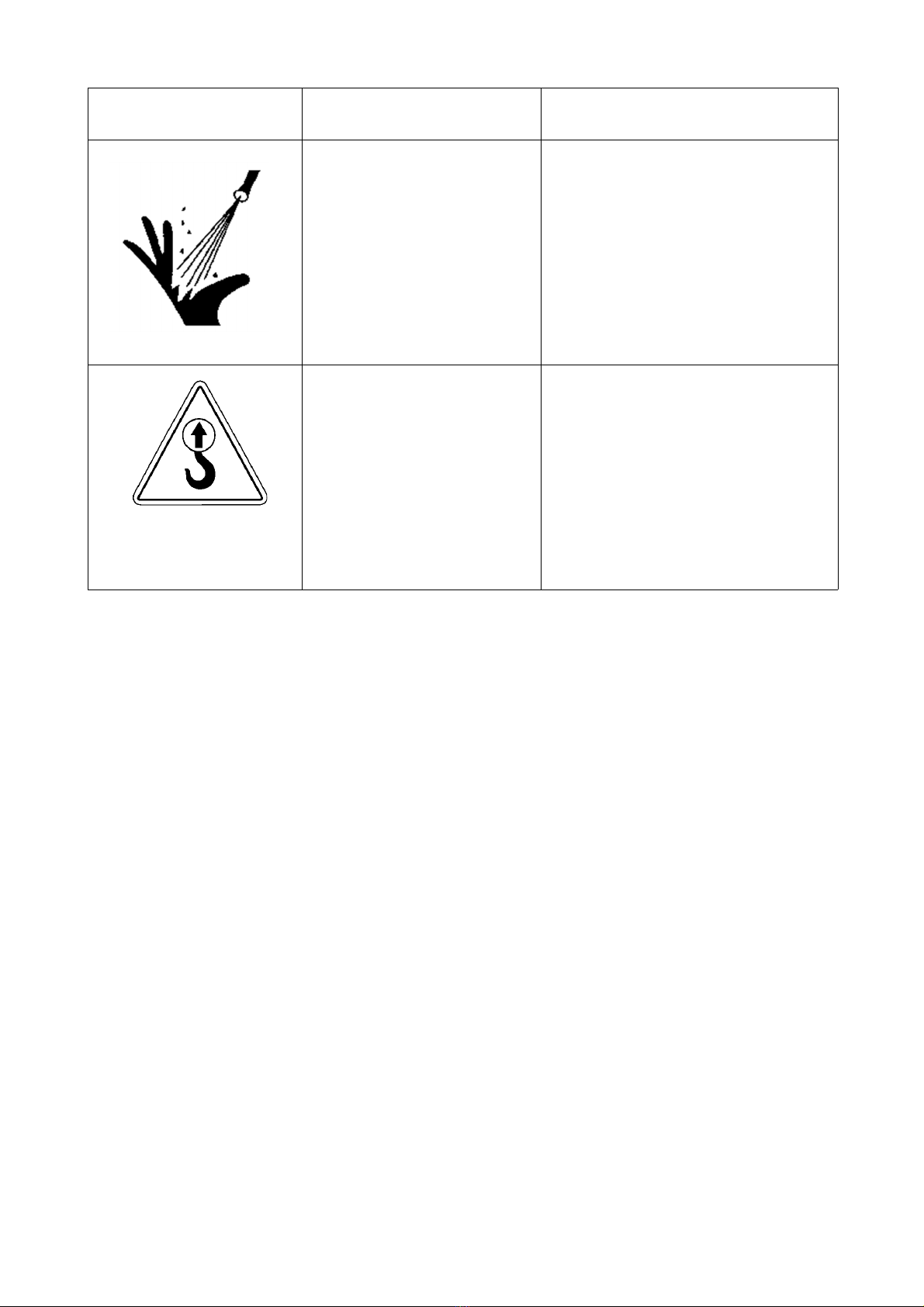

Safety marking Meaning of the

safety marking

Stream of liquid under

pressure – risk of injury

Place for attachment of

transport belts

Place located on the piece

of machinery

Actuators

Upper section of hitching bar

(upper link bolt)

6

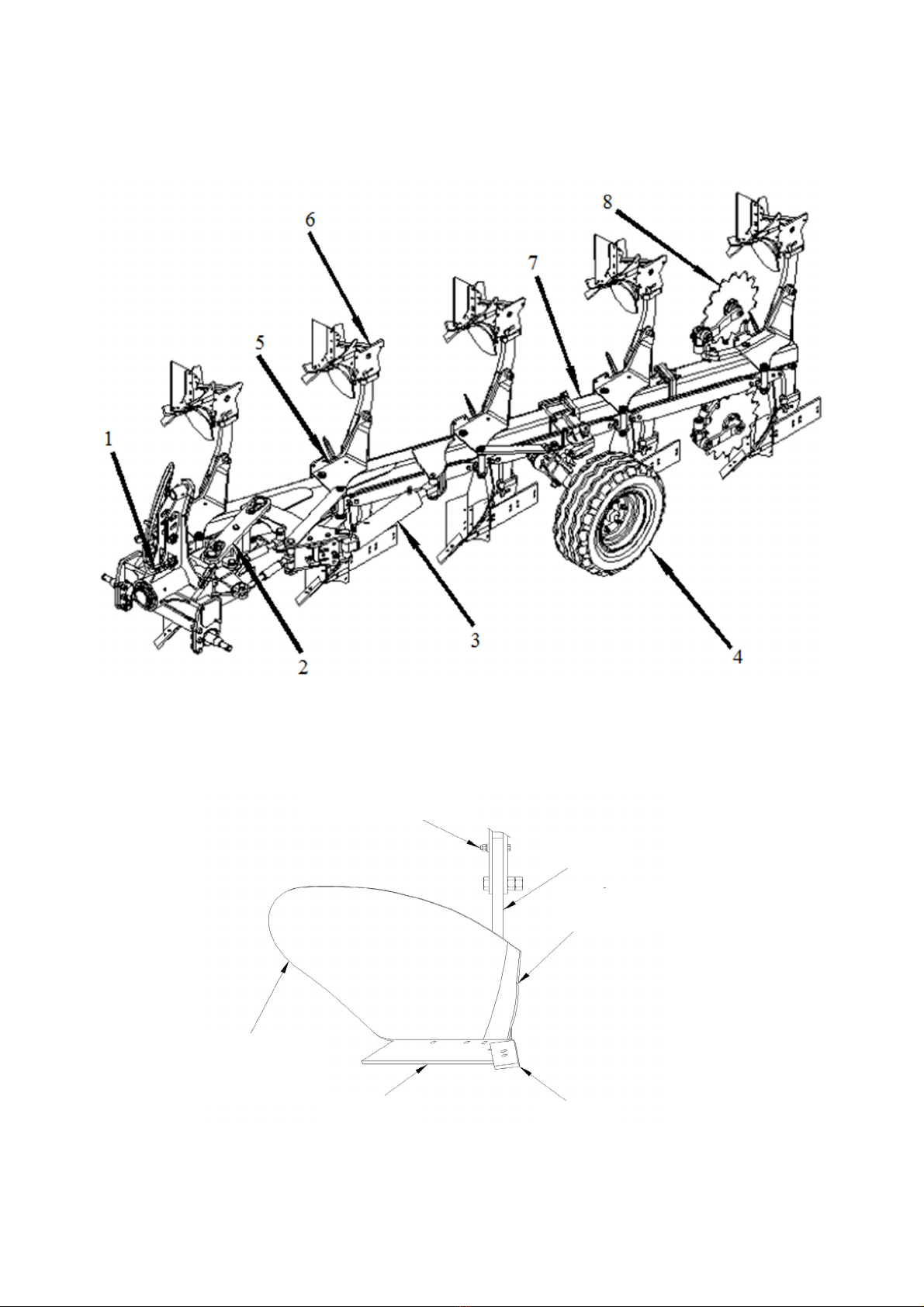

sheer bolt

plough

standard

mouldboard

breast

chisel

plough share

mouldboard

wing

2 General Information

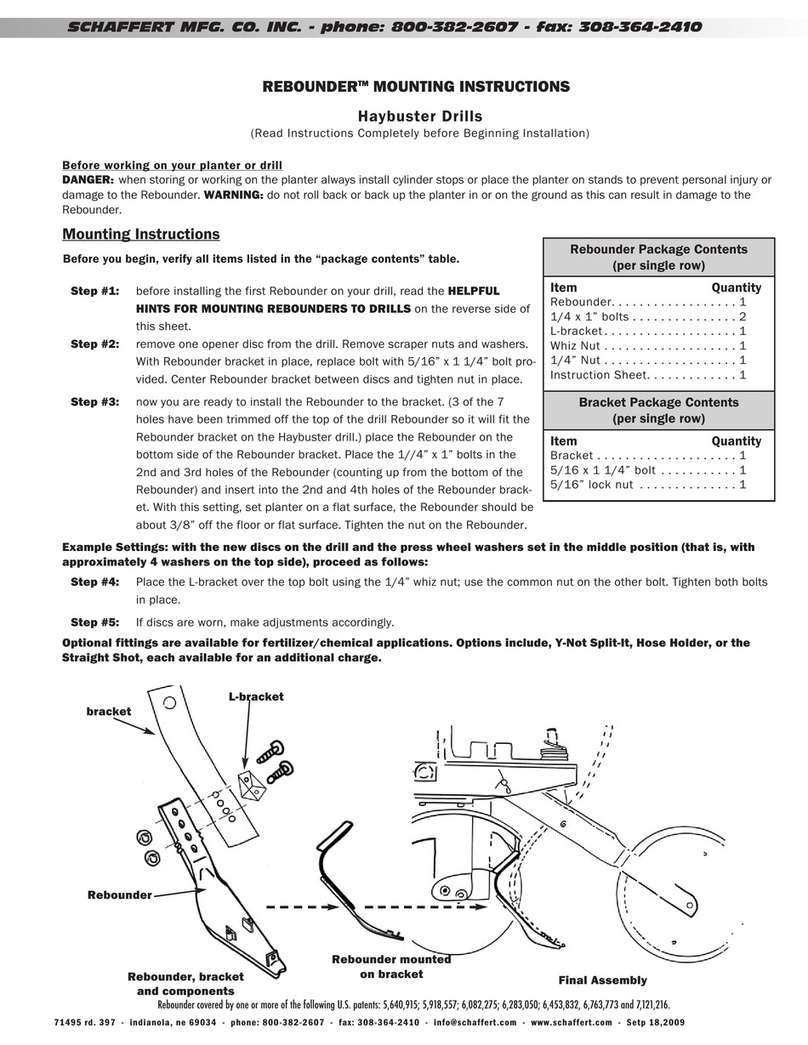

2.1. Construction of the ORKAN VARIO plough

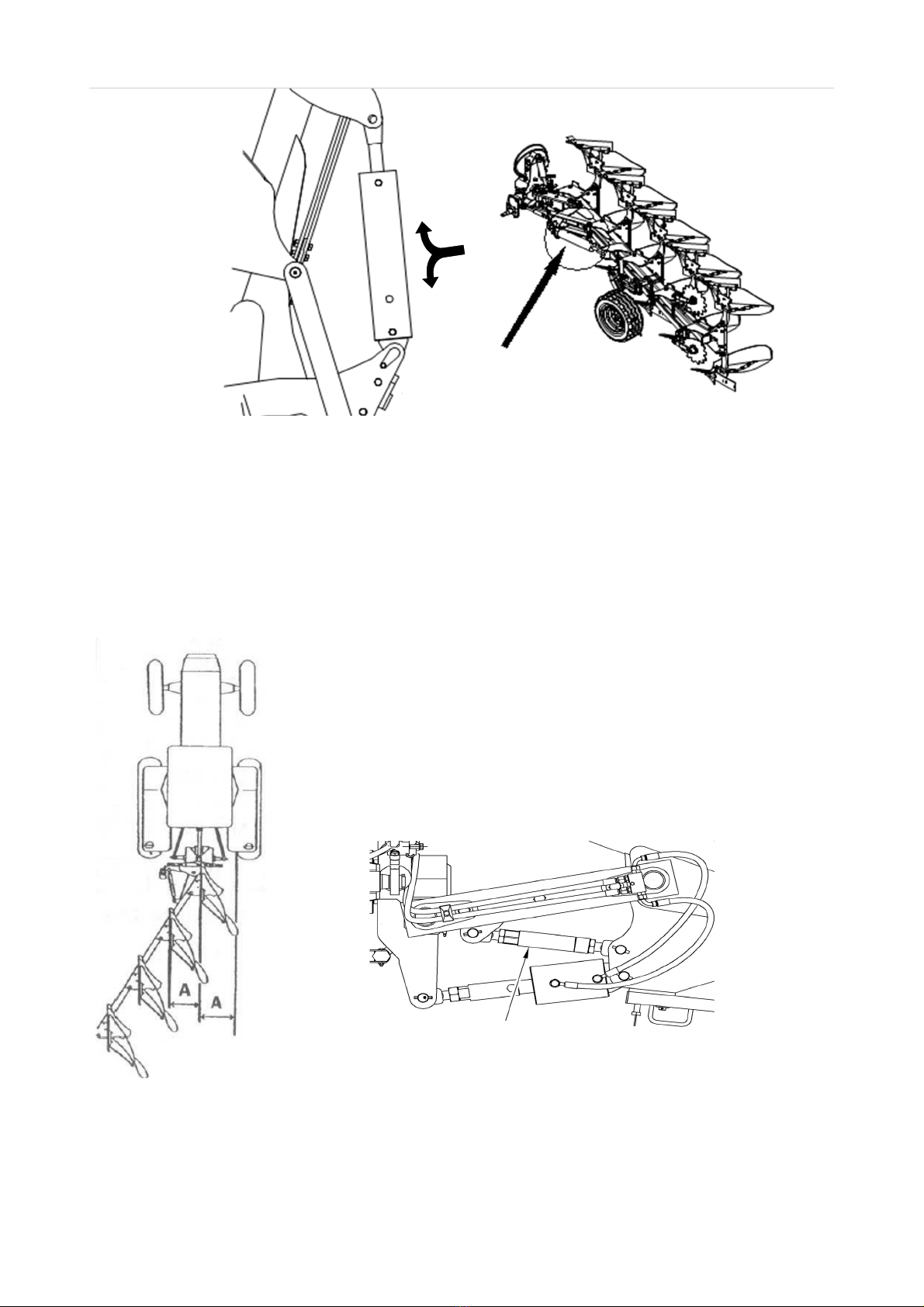

The ORKAN VARIO plough’s construction: 1-head; 2-connector; 3-actuator for smooth

adjustment of VARIO’s furrow width; 4-gauge wheel; 5-plough body handle; 6-plough body;

7- main frame; 8-rolling coulter.

7

2.2. Intended use of the ORKAN VARIO plough

The ORKAN VARIO plough is designed to plough soils containing few stones. Its purpose is to

cut up eld’s earth, lift and turn it over in order to cover over crop residue and to loosen the soil.

Its working elements are right- and left-hand plough bodies equipped with “18”

shares, reversible chisels, and full half-screw or openwork cylindrical mouldboard

Table 2. Description of the individual working components of the ORKAN VARIO plough.

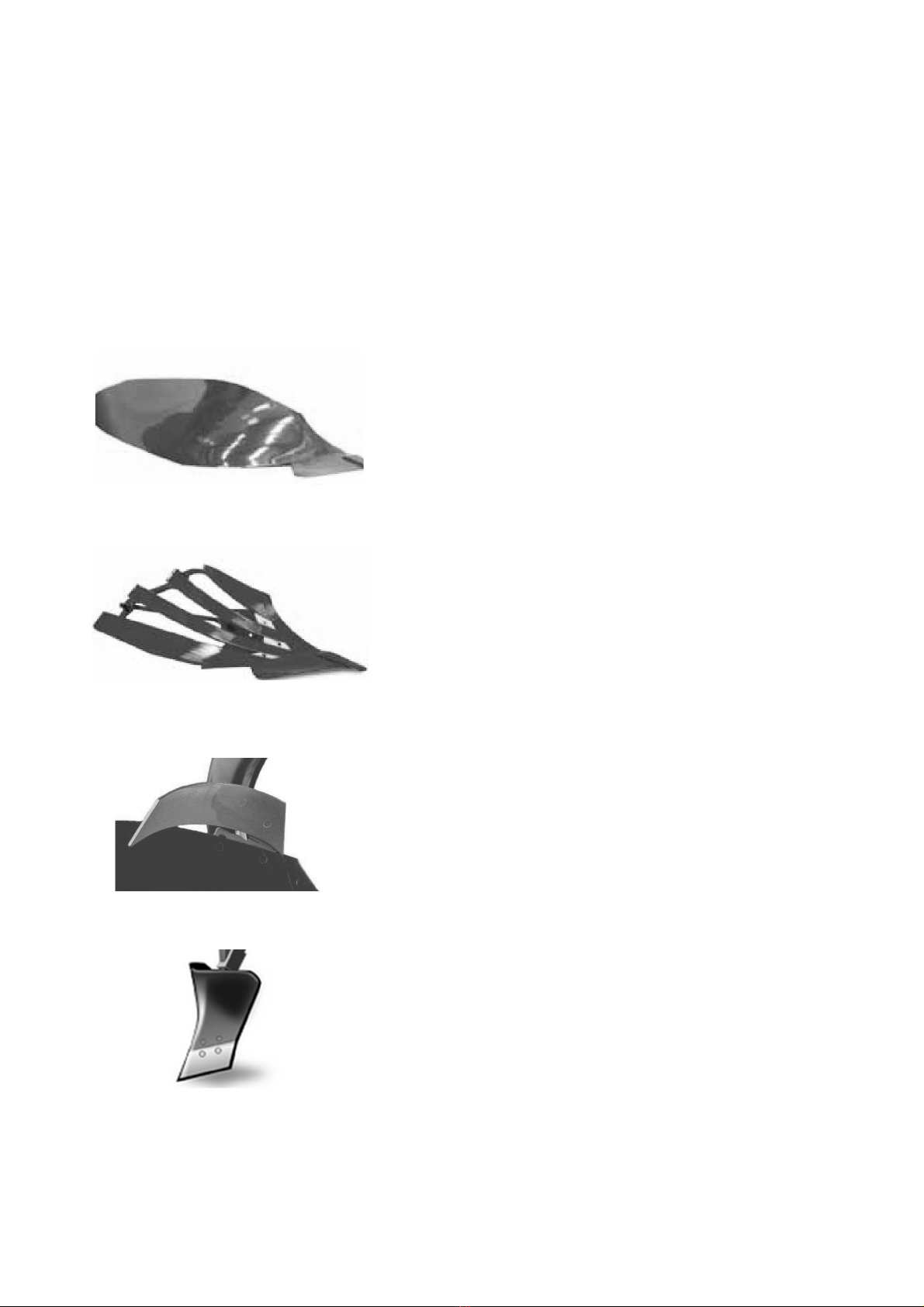

Full half-screw mouldboard

Recommended for medium and light soils. Ideal for

covering over crop residues and characterized by a low

soil loosening intensity. It creates a wide furrow, which

allows it to be used in cooperation with tractors having

wide tires.

Openwork cylindrical mouldboard

Recommended for heavy (compacted) soils. Ideally

loosens the soil and thanks to the mouldboard being

of an openwork structure, ploughing resistance is

reduced.

Scraper (trash board)

Provides good coverage of crop residues and organic

fertilizers. Allows for a large space to be maintained

between the plough bodies.

Skim coulter

Recommended for ecient deep ploughing on soils with

a large amount of crop residues and stubble (especially

corn for medium to shallow ploughing) and organic

fertilizers

8

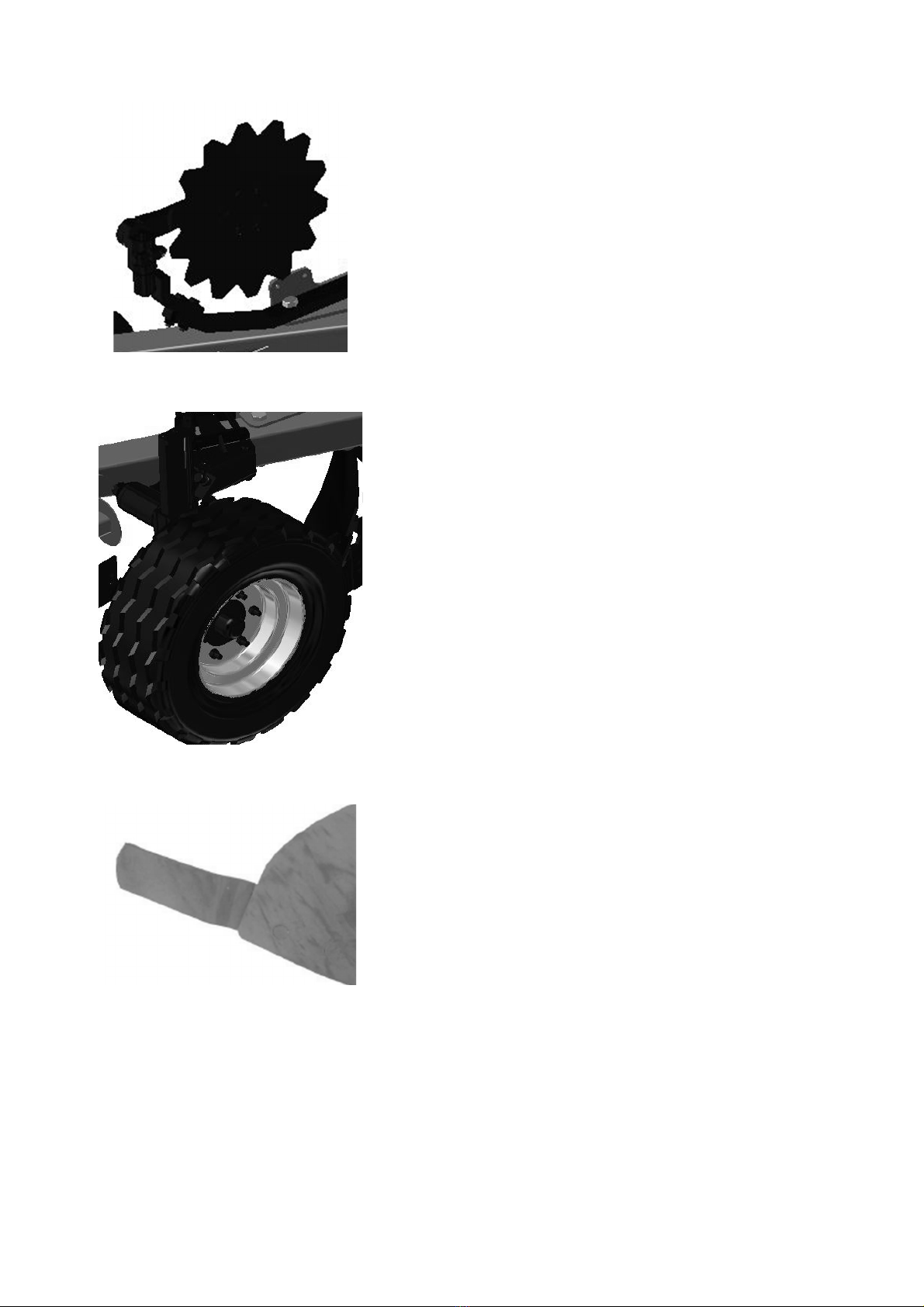

Gauge wheel

Shin

The rolling coulter is mounted on the end pair of plough

bodies to ensure a suitable furrow shape. It puts up

lower operating resistances compared to the knife cut

form of ploughing.

This ensures furrow depth is maintained and longitudinal

ploughing to ensure uniform depth of the furrow,

regardless of surface irregularities.

This ensures correct arrangement of the furrow especially

during the ploughing of stubble and areas covered by sod.

9

Rolling coulter

Alternative to the rolling coulters when reduction of

mass is necessary. It is also recommended for large

quantities of crop residues, organic fertilizers or stony

soils when a rolling coulter would be blocked

WARNING! This plough is exclusively intended for agricultural work - soil

cultivation. Using it for other purposes will be construed as improper use

and will result in loss of warranty.

WARNING! The manufacturer is not responsible for damage caused by

misuse of the machinery. Failure to comply with the instruction manual

will also be construed as misuse.

3 General safety precautions

The plough can only be started, used and repaired by persons familiar with its

operation and that of the tractor being used and the rules for its safe use and operation.The

manufacturer will not be responsible for any arbitrary modications of the construction of

the plough. Only “MANDAM” factory parts should be used during the warranty period.The

plough should be operated with caution and in particular:

• Before starting each ploughing operation, check the plough and the tractor whether

their condition guarantees safety during operation and travel,

• It is forbidden for the agricultural machinery to be used by a minor, anyone sick, or

after drinking alcohol or using other intoxicants,

• During work on this plough, one should use appropriate clothing, footwear and work

gloves,

• Do not exceed the permissible axle loads, tire pressures or transport dimensions,

• Only original pins and cotters should be used,

• Do not approach the plough while it is being lifted or lowered,

• Do not stand between the tractor and the plough when the engine is running,

• Driving the agricultural machinery, or raising and lowering it must be performed

slowly and gently without violent jerks, making sure that no bystanders are close to

the machinery,

• Do not reverse the tractor or make turns when the agricultural machinery is lowered

into the operating position,

10

Coulter

• Do not use the tractor’s independent brakes while making turns,

• Do not stand on the agricultural machinery or add any additional loads when it is in

operation or being transported,

• Take special care when making turns if bystanders are close by,

• Do not operate the plough on inclinations greater than 12º,

• Only make repairs, lubricate or clean the working parts with the tractor engine

turned o and the plough lowered,

• Do not carry out maintenance or replacement of parts beneath the agricultural

machinery without proper protection, as head injuries may occur - use a hardhat,

• During breaks in its operation the agricultural machinery should be lowered to the

ground and the tractor engine turned o,

• The plough is equipped with a mechanical lock that blocks the plough’s uncontrolled

rotation during transport,

• Driving and parking this machine on sloping unstable ground may lead to its slipping,

• Maintain the agricultural machinery in a manner that prevents injury to humans and

animals.

3.1. Hitching and unhitching to a tractor

• Make sure that the plough is connected to the tractor in accordance with the

instructions, remembering to secure the bolts and that the bolts are secured with

cotter pins.

• During towing of the plough by tractor it is forbidden to get between the agricultural

machinery and the tractor.

• The tractor working with the plough must be fully operational. It is prohibited to

connect this piece of machinery with a tractor with a hydraulic system that is not

fully operative.

• One must remember to keep the tractor’s balance with the plough and maintain its

steering and braking ability - the front axle load must not fall below 20% of the total

axle load of the tractor – use the set of front end counterweights.

• In a resting position, the agricultural machinery should maintain a stable equilibrium

and be disconnected from the tractor.

• The plough’s support stand should rest on stable ground. It is forbidden to use pads

under the support as this may cause instability.

3.2. Tyres

• The tyre pressure must not exceed the tyre manufacturer’s recommended tyre

pressure rating (as indicated on the tyre wall).

• Badly damaged tyres (especially damage to the prole) must be replaced

immediately.

• Repair work on wheels or tyres should be carried out by trained and authorized

personnel. These jobs should be carried out using appropriately selected tools.

11

lock lever

3.3. Hydraulic system

The hydraulic system works under high pressure. All precautions must be taken and in

particular:

• Do not connect or disconnect hydraulic lines when the hydraulic system of the

tractor is under pressure (hydraulics set to neutral).

• Regularly check the condition of connections and hydraulic lines,

• When repairing any hydraulic breakdown, the plough should be disconnected from

its power source.

3.4. Transport on public roads

For transporting the plough, it should be turned to the middle position (the frame should

be on the same axis as the tractor), then locked with the bolt. Prior to being rotated,

lift the plough to a level where it will not come into contact with the ground. During

transportation, the clearance under the lowest part of the plough should prevent it from

coming into contact with the ground during transportation on uneven surfaces. When

taking the plough onto public roads, it is mandatory to use driving lights, a distinctive

warning sign and side reectors.

Do not exceed the appropriate speed limits during transportation, which are:

• up to 20 km/h on roads with smooth asphalt surfaces

• 6-10 km/h on country roads or cobblestones

• not more than 5 km/h on bumpy roads

The driving speed must be adjusted to the road conditions and conditions prevailing on

the road so that the plough does not jerk the tractor’s suspension system and there is no

excessive load on the plough’s frame or tractor’s suspension.

Take special precautions when passing other vehicles, overtaking, and turning. The

permissible width of the agricultural machinery moving on public roads is 3.0 m.

It is forbidden to transport the plough over any area where the inclination of the slope

transversely to the plough exceeds 7º.

Be aware of the length of the plough. On sharp turns the plough turns in the opposite

direction to the direction of the turn. This may result in a collision with obstacles or other

road users.

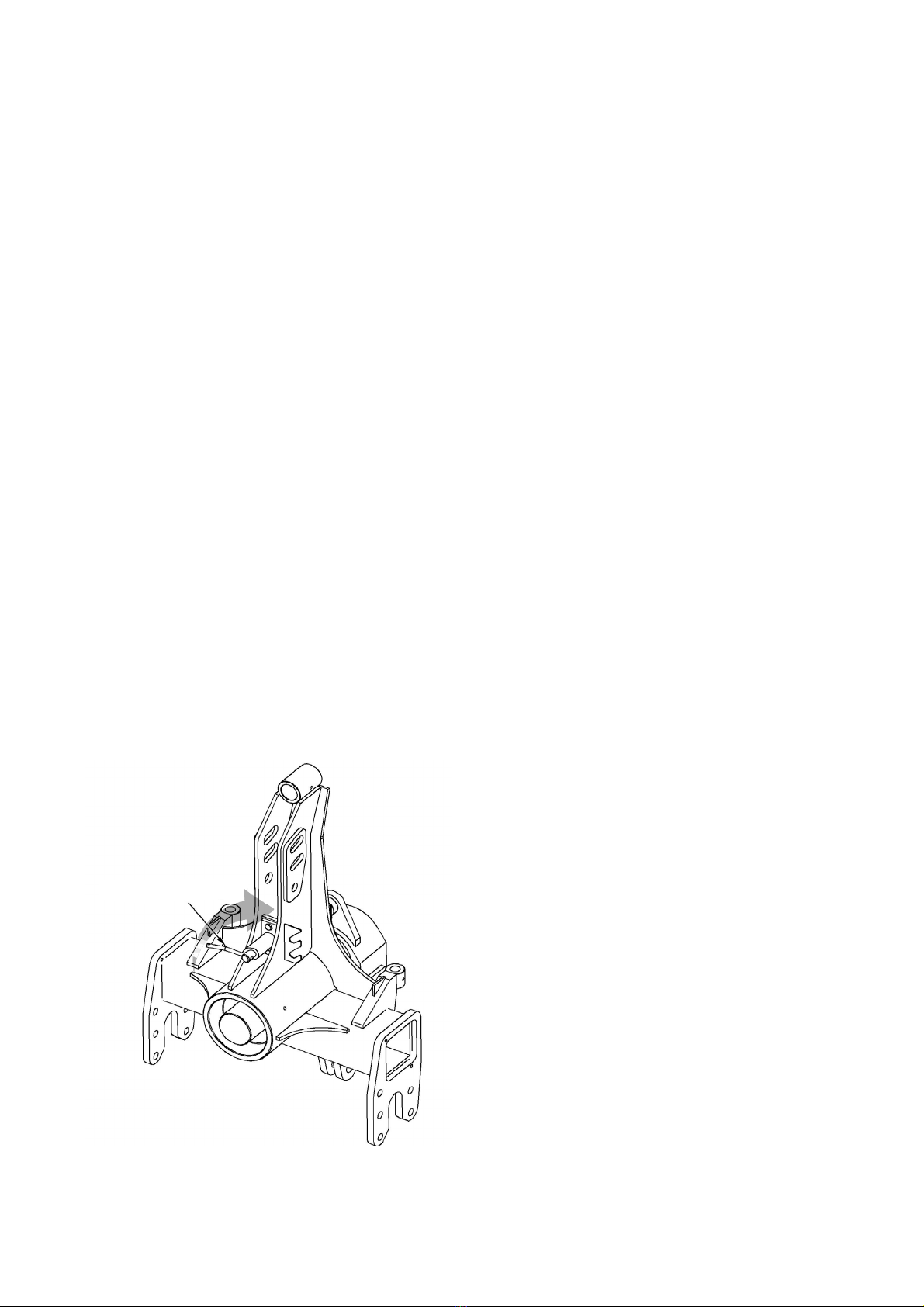

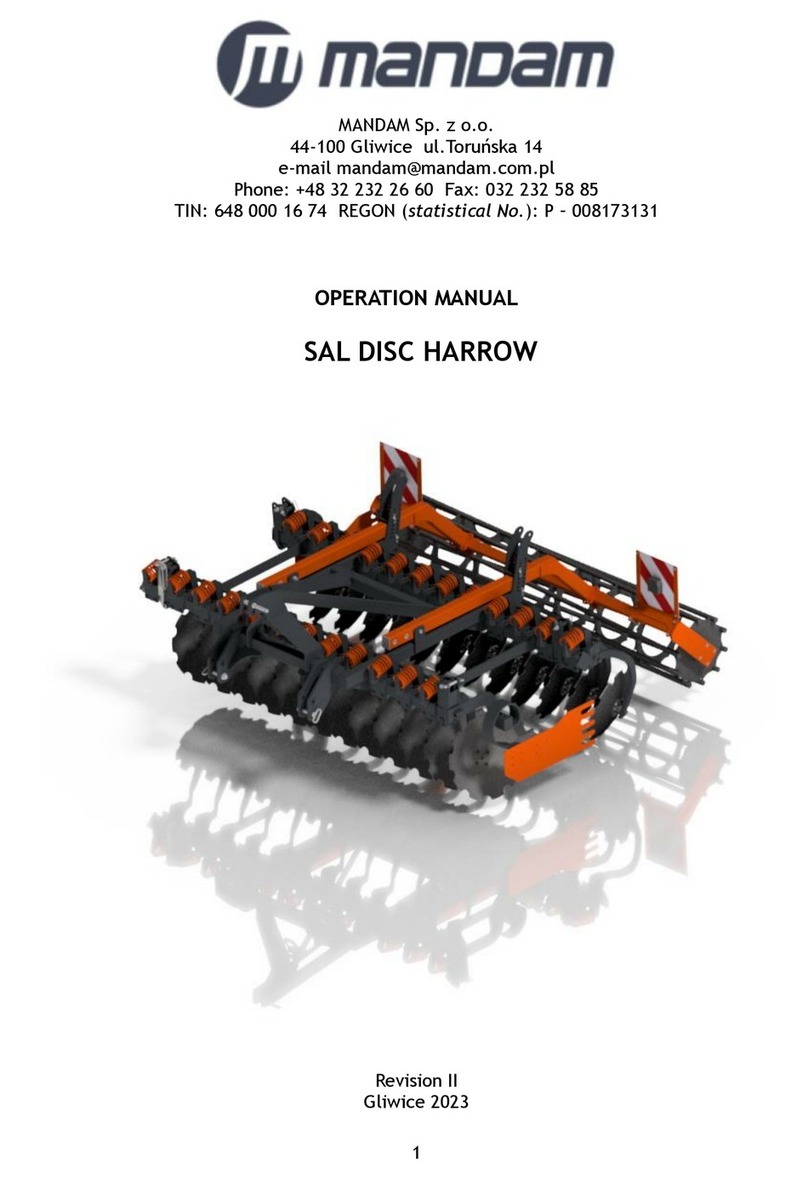

During transport the plough is to be secured

with the lock that keeps the plough on the

same axis as the tractor, reducing its transport

width and increasing the stability of the

vehicle during transport. For locking, use the

lever that you need to turn so that it jumps

out of its slot and so that the pin holds the tow

bar head in the locked position. Once locked,

the plough cannot be turned because damage

to it may occur. To unlock, turn the lock lever

so that it falls back into its slot.

12

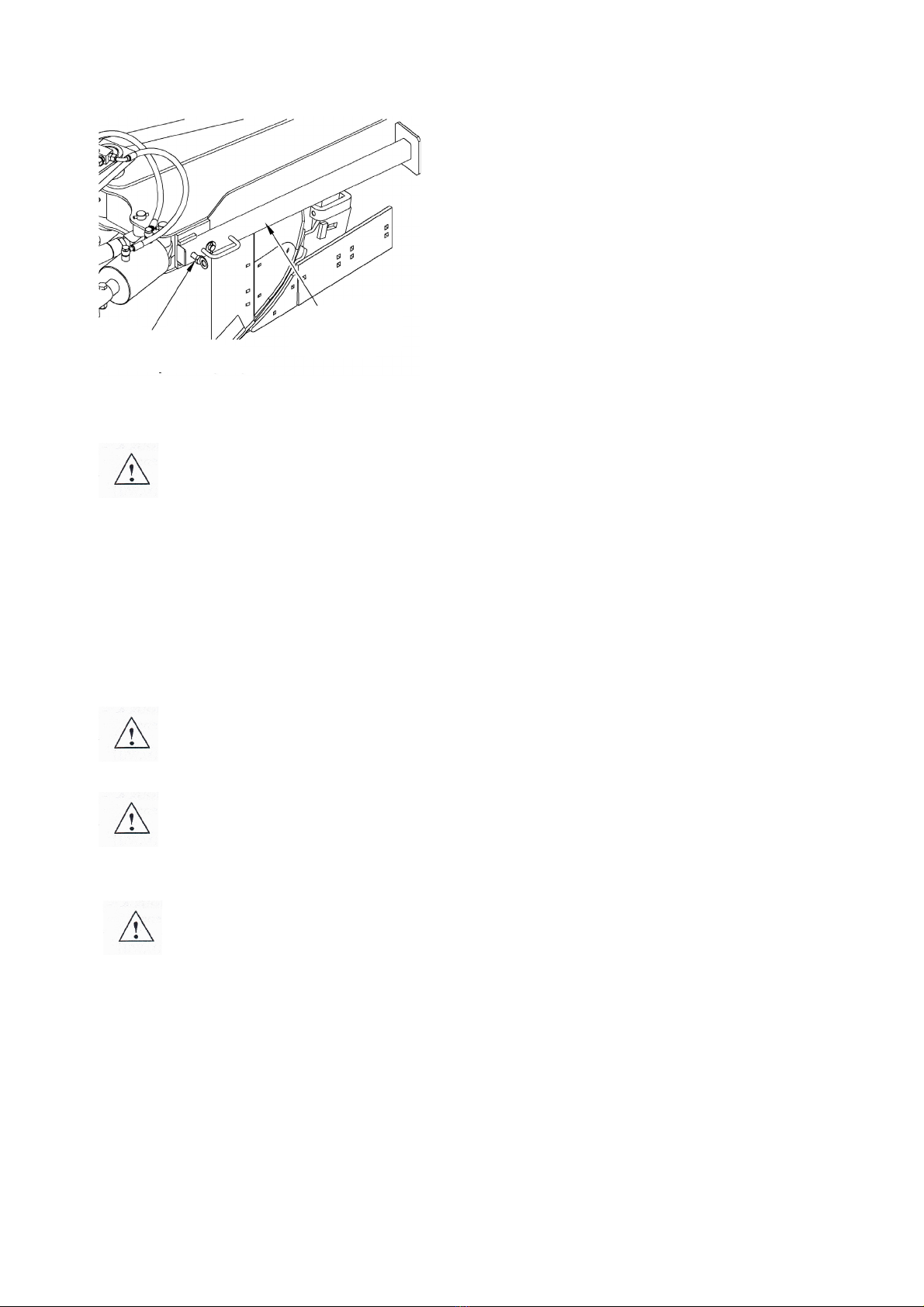

support

stand

safety pin

When the plough is parked, the support stand

must be secured to stop the plough overturning.

To this end, pull the safety pin, then take hold

of the support stand’s handle and pull it toward

you. Turn the support stand to the support

position (a 90º rotation) and release the handle.

WARNING! Take care when transporting the plough. It is forbidden to travel

on public roads without appropriate additional warning signs.

Thoroughly clean the agricultural machinery of all crop residues and earth before travelling

on a public road. Portable warning lights and a distinctive warning sign for slow-moving

vehicles (according to current trac regulations) should be mounted on the end of the

plough’s frame.

During transportation the plough should be raised to such a height that the minimum

clearance under the agricultural machinery is a minimum 25 cm.

WARNING! Moving this plough on public roads without warning signs and lights

required by the trac regulations may be dangerous and cause an accident.

WARNING! Warning signs and lights are not part of the plough’s equipment.

You can purchase them at points of sale for agricultural machinery.

Warning! Failure to adhere to the above may present a risk to the operator

and bystanders, as well as cause damage to the agricultural machinery. Any

damage resulting from non-compliance with these rules is the responsibility

of the user.

13

3.5. Description of residual risk

MANDAM sp. z o.o. makes every eort to eliminate the risk of accident. However,

there is a degree of residual risk that may cause an accident. The greatest danger occurs

when:

• using the agricultural machinery for purposes other than those described in the

instruction manual,

• the agricultural machinery is used by minors without permission, by anyone that is

sick, or under the inuence of alcohol or other intoxicants,

• people or animals come too close to the agricultural machinery,

• insucient care is taken when transporting and manoeuvring with the tractor,

• anyone gets between the agricultural machinery and the tractor while the tractor’s

engine is running,

• the plough is in operation or when its instruction manual are ignored,

• travelling on public roads.

3.6. Residual risk assessment

Residual risks can be minimized by following the recommendations below:

• careful operation of the agricultural machinery without undue haste,

• careful reading of the instruction manual,

• maintaining a safe distance from hazardous areas,

• adhering to the rule about not riding on the agricultural machinery or coming too

close to the moving parts of the agricultural machinery while the tractor engine is

running,

• performing all maintenance work in accordance with the safety precautions,

• using protective clothing and, if any work needs carried out beneath the agricultural

machinery, wearing of a hardhat,

• preventing unauthorized access to this piece of machinery, especially children.

14

0-10 cm greater than the rear

tyres

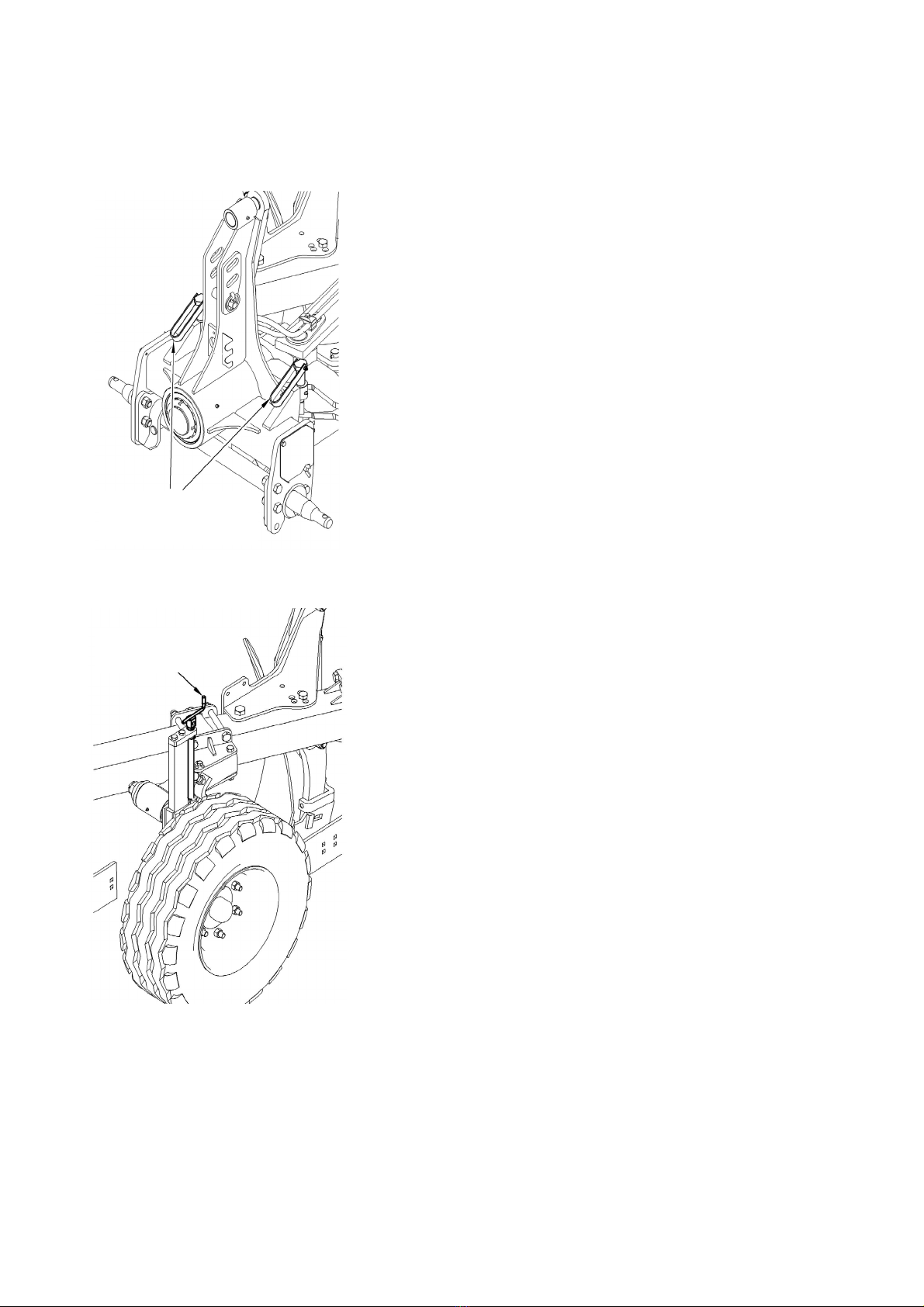

4 Plough and tractor settings

The tractor selected for use with this plough should have the characteristics described in

the following paragraphs. The hydraulic system must be ecient and have two pairs of

hydraulic couplings in accordance with ISO 7241-1 A, controlled by a twin distributor. The

pressure in both rear tyres of the tractor should be the same value to avoid the formation

of uneven ridges.

Recommendations for the tractor:

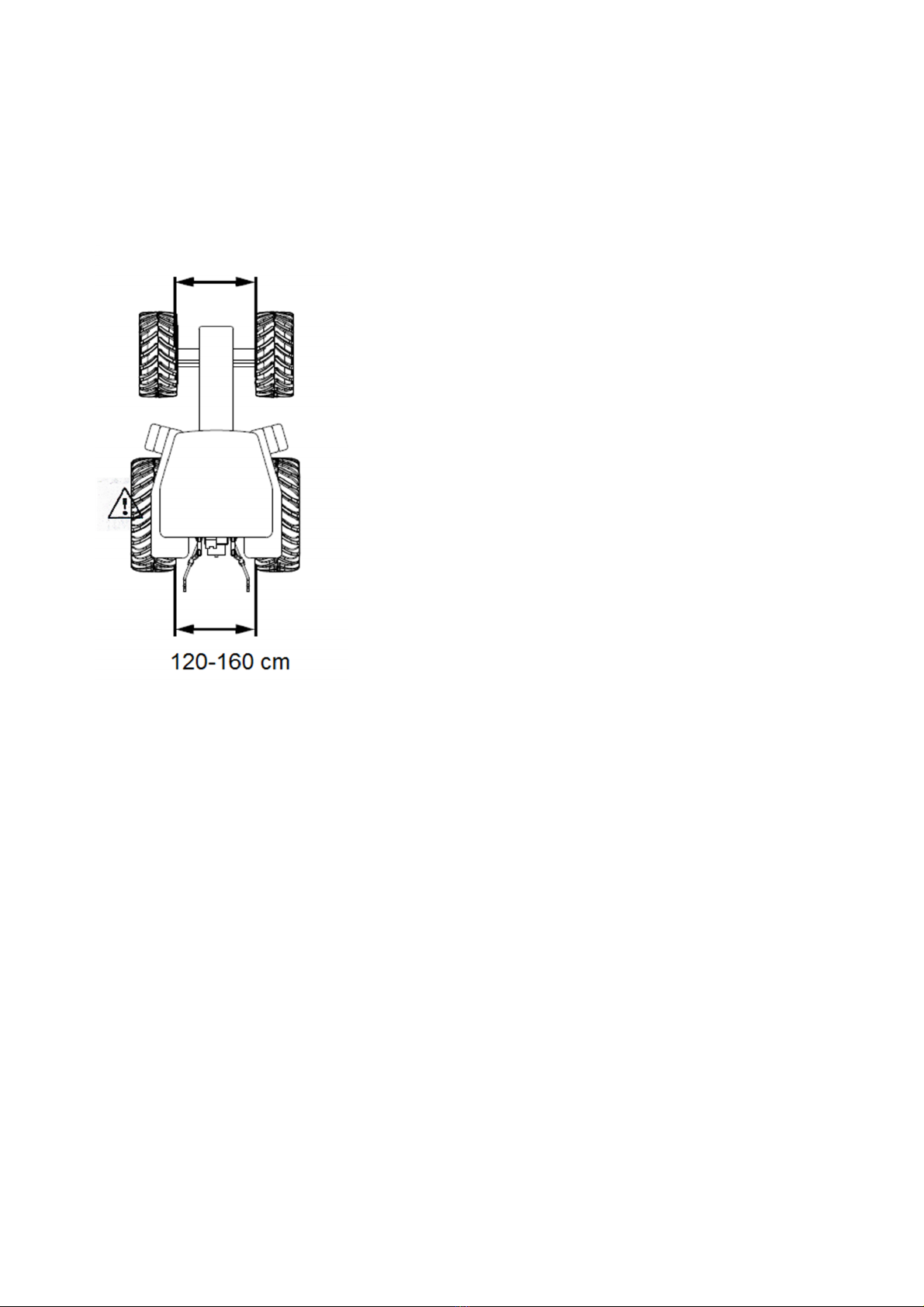

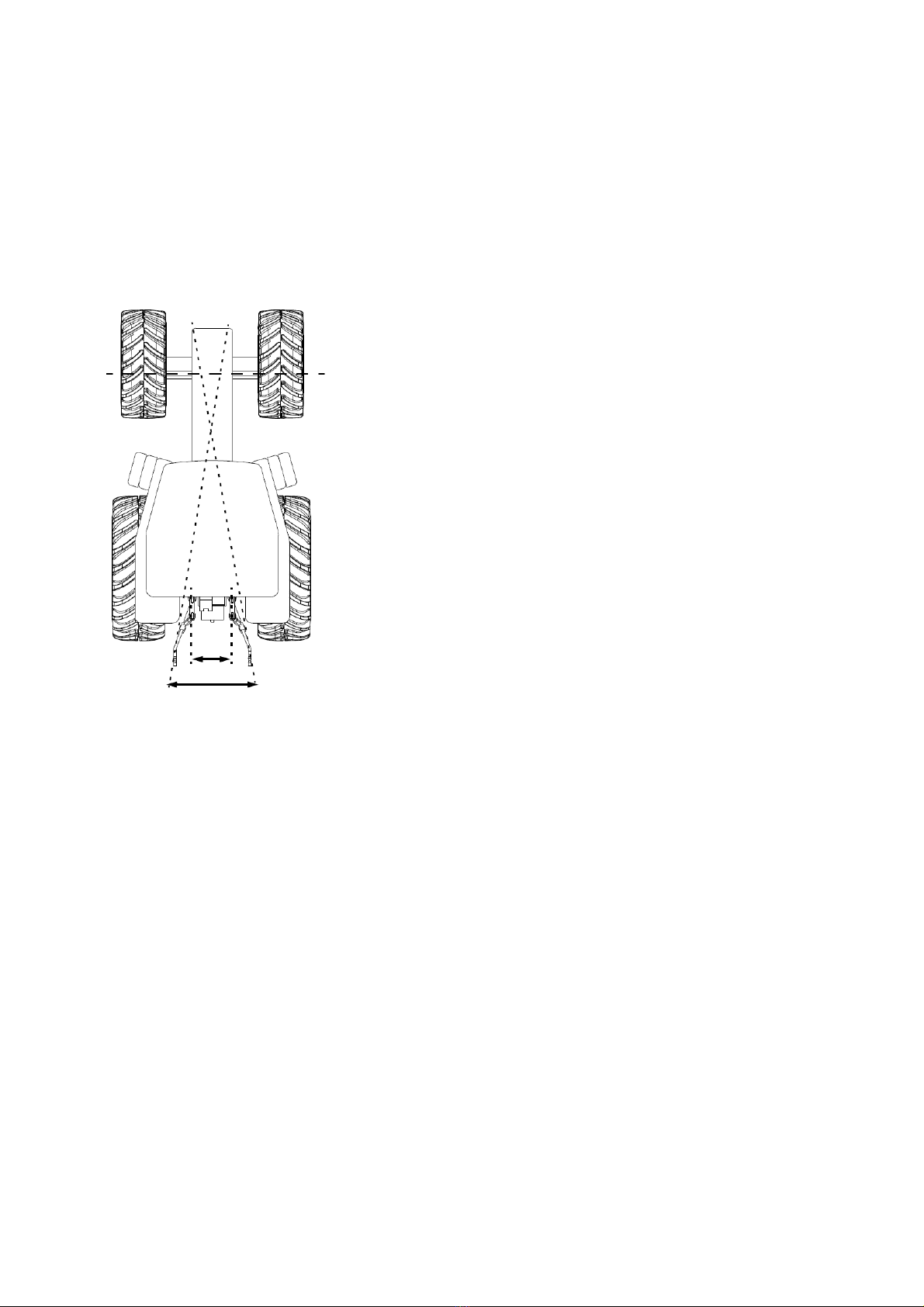

• The recommended distance between the far inner

points of the rear tyres (without the use of a furrow

extender) should be 120 - 160 cm,

• The recommended distance between the far inner

points of the front tyres should be 0 - 10 cm greater

than for the rear tyres

WARNING! The permissible loads on the axles and tyre

load capacities must not be exceeded. The front axle

load may not be less than 20% of total axle loads.

15

Axle load calculations

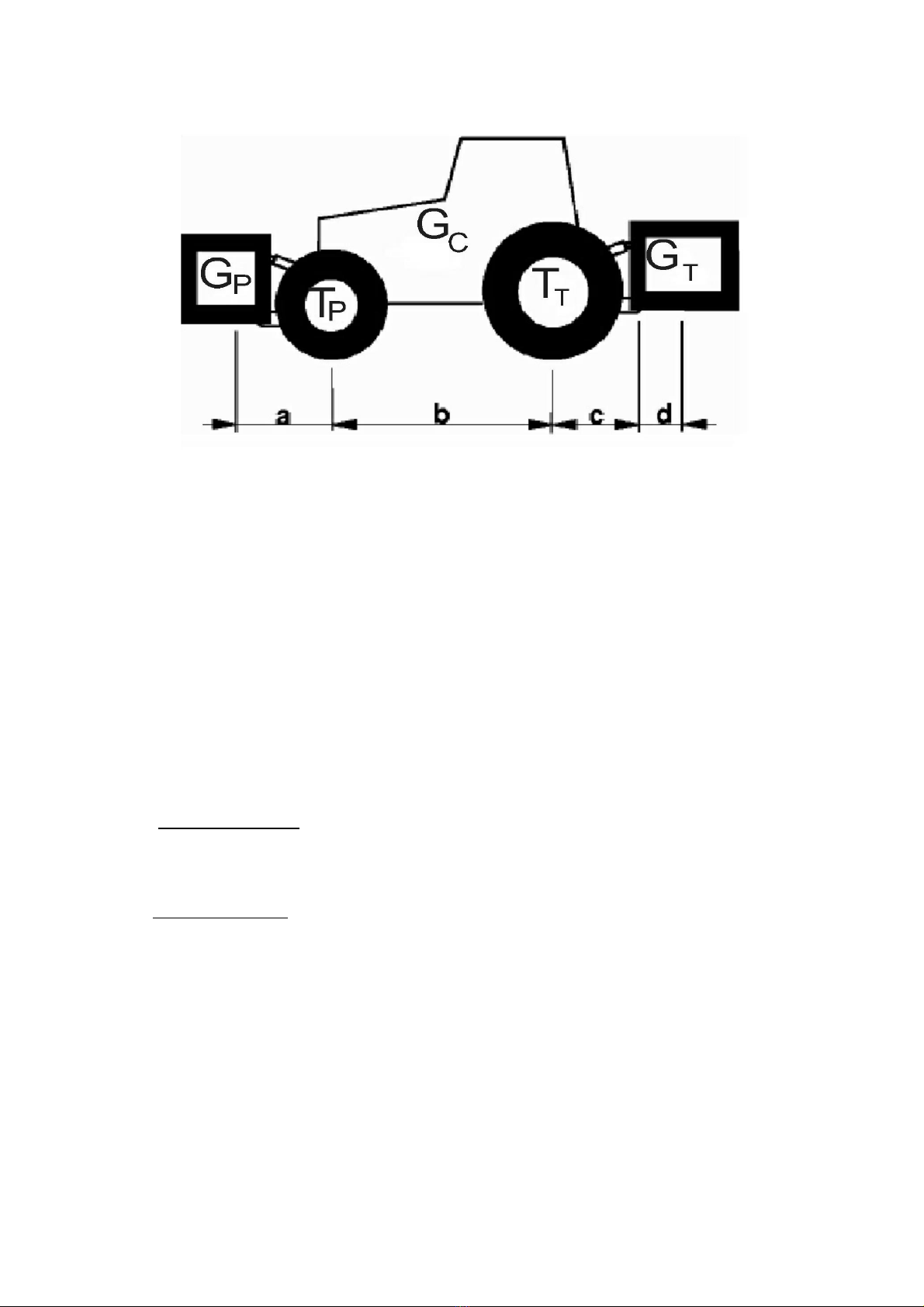

Signs:

GC – the tractor’s gross weight,

TP – front axle load for the unhitched tractor,

TT – rear axle load for the unhitched tractor,

GT – total weight of the equipment attached at the back,

GP – total weight of the equipment attached at the front,

a – the distance between the centre of gravity of the equipment attached at the front

and the centre of the front axle,

b – wheelbase of the tractor,

c – the distance between the centre of gravity of the rear axle and the centre of the

hitching pin of the equipment at the back,

d – the distance from the centre of gravity of the agricultural machinery to the hitching

pins of the tractor,

x – the distance of the centre of gravity from the rear axle (if the manufacturer does not

specify, one should make this 0.45).

The minimum front load when attaching the agricultural machinery to the rear of the tractor:

GPmin= GT⋅cd−Tp⋅b0,2⋅GC⋅b

ab

Actual load on front axle:

TPtot= GP⋅(a+b)+Tp⋅b−GT⋅(c+d)

b

Actual total weight:

Gtot=GPGCGT

Actual load on rear axle:

TTtot=Gtot−TPtot

16

wrong

4.1. Preparing the plough

The plough is usually delivered ready to be used. Due to transport limitations, it

may also be at times delivered partially dismantled. Check the technical condition of the

plough, especially the moving parts and all bolt connections, before commencing work.

4.2. Selection of the hitching bar

In order to obtain a rst ridge of a stable width, the

theoretical line of intersection of the lower connectors of

the tractor’s suspension system should be at the distance

of 1/3 of the tractor’s wheelbase behind the front axle.

Failure to do this may cause the plough to “slew”. In such

a case, a hitching bar of a dierent length must be used.

4.3. Hitching the plough to the tractor

The TUZ lower connectors should be at the same height, spaced apart by a distance

corresponding to the space between the lower plough suspension points. When hitching the

plough to the tractor, the agricultural machinery should stand on a hard and level surface.

When hitching the two pieces of machinery together the following must be carried out:

• Suspend the hitching bar on the lower connectors of the TUZ and secure with cotter pins,

• Switch the hydraulic system of the tractor to the positioning adjustment,,

• Carefully reverse and hitch the agricultural machinery onto the hitching bar and then

secure it with the bolts,

• Connect the tractor’s upper connector (when the plough is in operation the xing

point of the upper connector on the plough should be positioned higher than the

xing point of that connector on the tractor),

• Check the raising, lowering and overall operation of the plough’s hydraulic system.

17

smaller

ploughs

larger ploughs

handle openings

handle bolts

hitching bar

hitching bar

handle

Connection of upper connector:

• Oval (longitudinal) holes allow for better

longitudinal ploughing of the terrain. Use for

4-5 furrow plough, in extreme cases 3-furrow

plough.

• A xed hole prevents the plough from rising up

on heavy and stony soils. Use for 2-3 furrow

ploughs.

4.4. Adjustment of the hitching bar height

The hitching bar can be set at the height of 64.5 cm and 57 cm from the ground depending

on the type of tractor operating the plough. In order to change the position of the hitching

bar, rst remove the hitching bar from the plough’s suspension system. Then turn the

hitching bar handle to the appropriate holes.

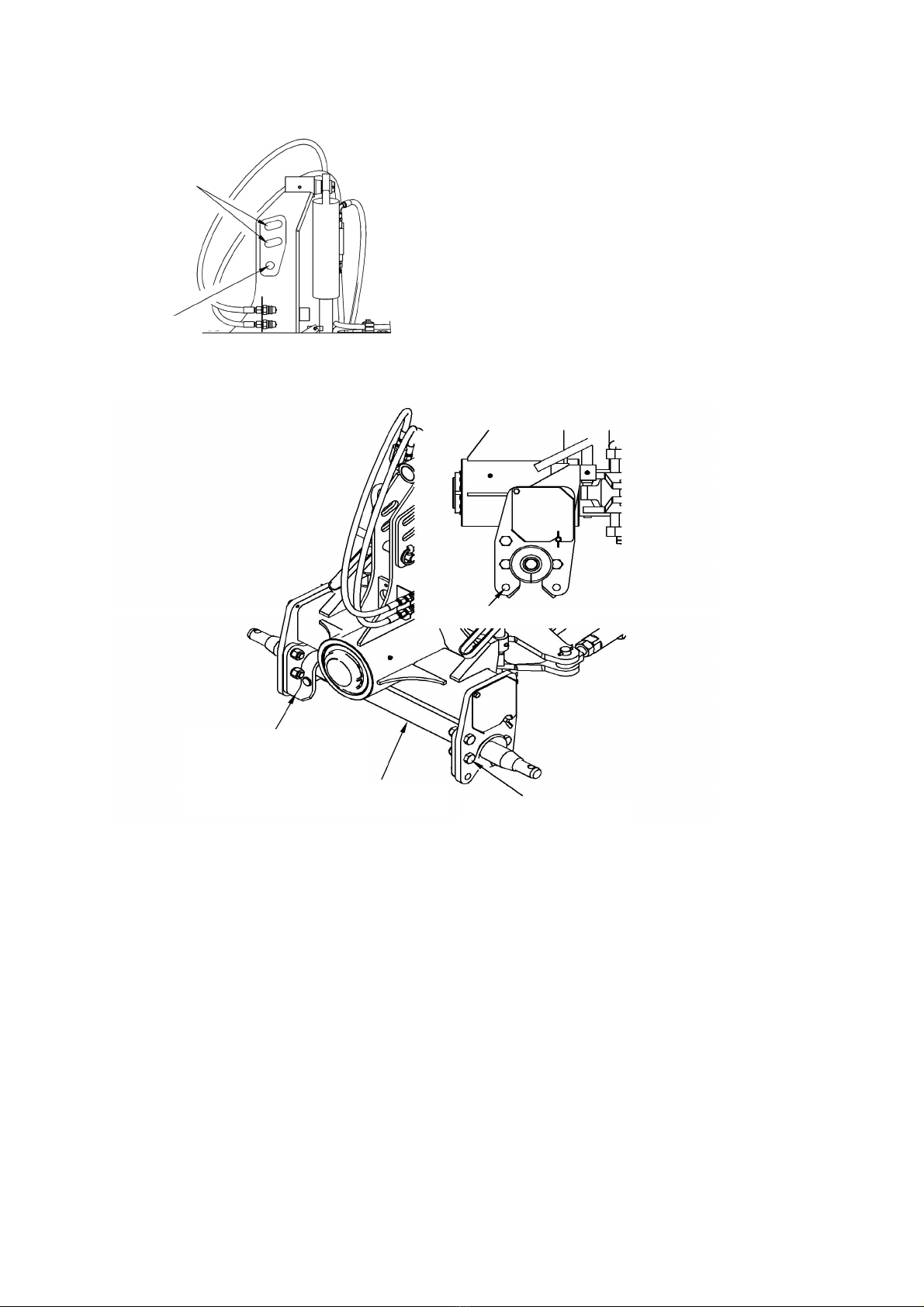

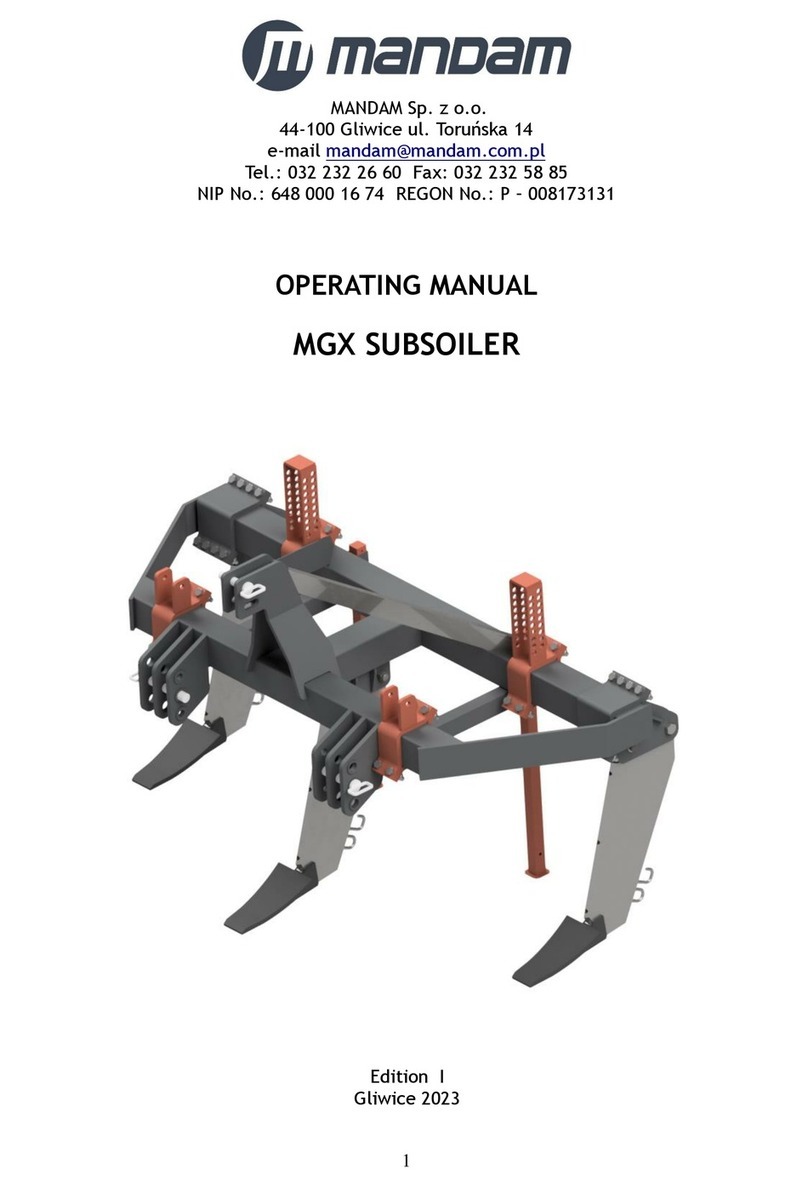

4.5. Adjustment of the furrow width

The ORKAN VARIO plough is equipped for an innitely adjustable furrow width. Changing

the furrow width is possible thanks to the use of a hydraulic actuator. The furrow width

can be smoothly adjusted, i.e. without steps, anywhere from 30 to 50 cm. The arrow in

the photo below shows the position of the furrow width adjustment actuator and its view

as seen from above.

18

bolt for adjustment

of the width of the rst ridge

Setting the optimum furrow width is of particular importance for reducing the working

resistance of the agricultural machinery and minimizing the degree of soil clumping

after ploughing. The operating width of a plough body must be adjusted according to

the weather conditions, terrain and the capabilities of the farm tractor. Indicated above

is the position of the actuator within the agricultural machinery and the direction of

its movement. Extension of the actuator reduces the furrow width, while the maximum

position of the actuator corresponds to the maximum furrow width.

4.6. Adjusting the rst ridge

The width of the rst ridge should correspond to the width of

the remaining ridges, but one should also take into account:

• resultant compensation of the plough’s operating resistance,

• with wide tractor tyres, the width of the rst ridge should

be reduced to ensure proper alignment of the front ridges,

• For a plough equipped with a furrow widener, the width of

the rst ridge should be reduced by 13 cm compared to the

width of the remaining ridges.

After altering the working width of the rst ridge, one may need to adjust the width of

the furrow.

19

transverse levelling

adjustment bolt

wheel adjustment

crank

4.7. Levelling

The plough is longitudinally levelled by means of the upper connector. The plough frame

should always be parallel to the ground. The upper connector bolt should be in the middle

of the longitudinal hole.

The plough is transversely adjusted using the bolts with

handles. There is separate adjustment for the left and

right sides. Looking at the plough from behind, the

plough’s beams should be positioned perpendicular to

the ground. With any change in the depth of the furrow,

a transverse levelling adjustment must be made

4.8. Adjusting the furrow depth.

When attaching the upper connector to the longitudinal

holes, it is necessary to set the furrow depth by means of

the tractor’s hydraulic (actuator/positional) regulation.

Setting the furrow depth on the gauge wheel is carried

out using a screw crank. The setting is the same for left

and right-hand side. Bumpers (screws with a counter nut)

allow the angle of the gauge wheel arm to be changed

relative to the ground. This allows you to change the

distribution of forces acting on the gauge wheel moving

over dicult terrain. Changing the angle of the gauge

wheel arm also results in the change to the depth of the

furrow.

20

This manual suits for next models

4

Table of contents

Other Mandam Farm Equipment manuals

Mandam

Mandam MGX 2200 User manual

Mandam

Mandam SAL DISC HARROW User manual

Mandam

Mandam SUPER User manual

Mandam

Mandam Hybro 3,0 User manual

Mandam

Mandam KNIFE ROLLER 3.0 User manual

Mandam

Mandam SPEC HD 2,5 User manual

Mandam

Mandam MBS User manual

Mandam

Mandam ORKAN 3+ User manual

Mandam

Mandam RHINO User manual

Mandam

Mandam GAL-K User manual

Popular Farm Equipment manuals by other brands

GREAT PLAINS

GREAT PLAINS BD7600 Original instructions

RITEWAY

RITEWAY ROCK PICKER 250 Operator's manual & parts

Land Pride

Land Pride CB1060 Operator's manual

AGT INDUSTRIAL

AGT INDUSTRIAL AGT-ECSSLR72 product manual

Wylie

Wylie Non-DOT Nurse Trailer Operator's & parts manual

Schlagel

Schlagel HD-1000 Series Operator's manual