Meanwell EDR-75-12 User manual

Other Meanwell Power Supply manuals

Meanwell

Meanwell SDR Series User manual

Meanwell

Meanwell RCP-1000 Series User manual

Meanwell

Meanwell KNX-20E-640 User manual

Meanwell

Meanwell SHP-30K-HV Series User manual

Meanwell

Meanwell HLG-240H-15 User manual

Meanwell

Meanwell DRA-40 Series User manual

Meanwell

Meanwell KNX-40E-1280D User manual

Meanwell

Meanwell RKP-1U-CMU1 User manual

Meanwell

Meanwell HEP-1000 User manual

Meanwell

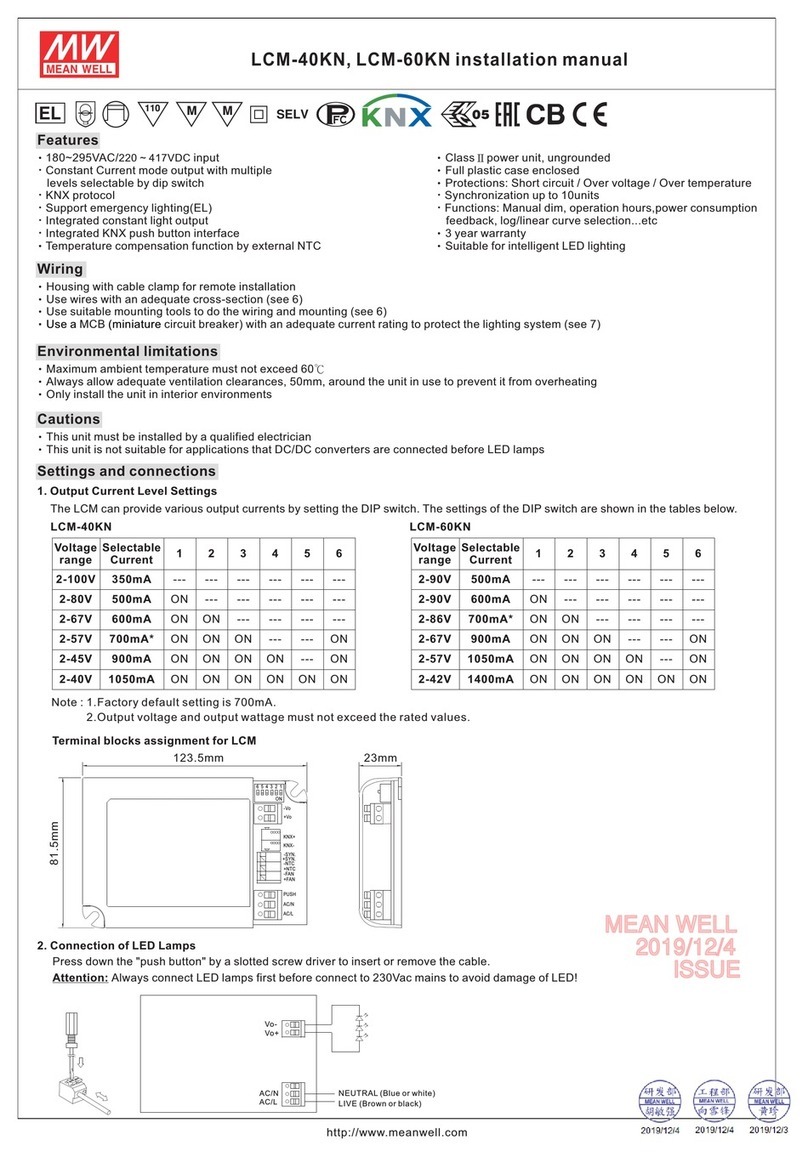

Meanwell LCM-40KN User manual

Meanwell

Meanwell DRS Series User manual

Meanwell

Meanwell DDR-120A-12 User manual

Meanwell

Meanwell SHP-10K Series User manual

Meanwell

Meanwell DR-15-12 User manual

Meanwell

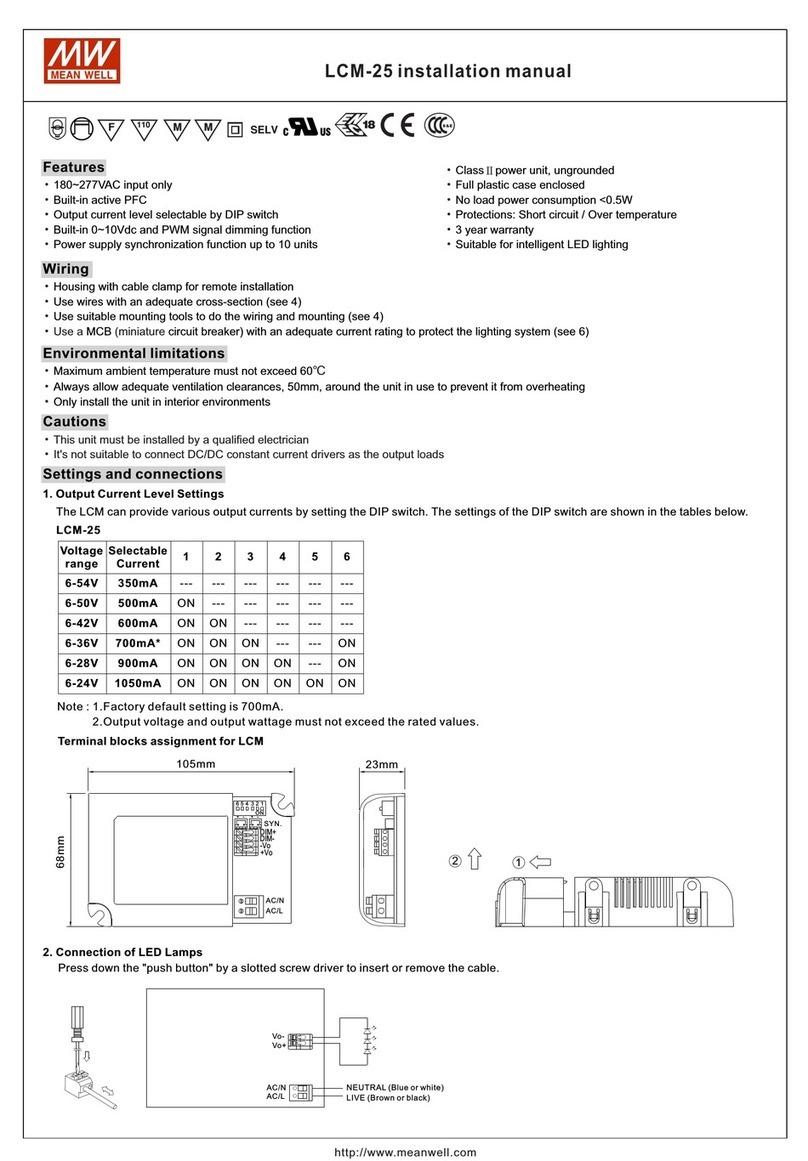

Meanwell LCM-25 User manual

Meanwell

Meanwell HEP-1000 User manual

Meanwell

Meanwell TDR-240-24 User manual

Meanwell

Meanwell DRP-3200 Series User manual

Meanwell

Meanwell RKP-CMU1 User manual

Meanwell

Meanwell MDR Series User manual

Popular Power Supply manuals by other brands

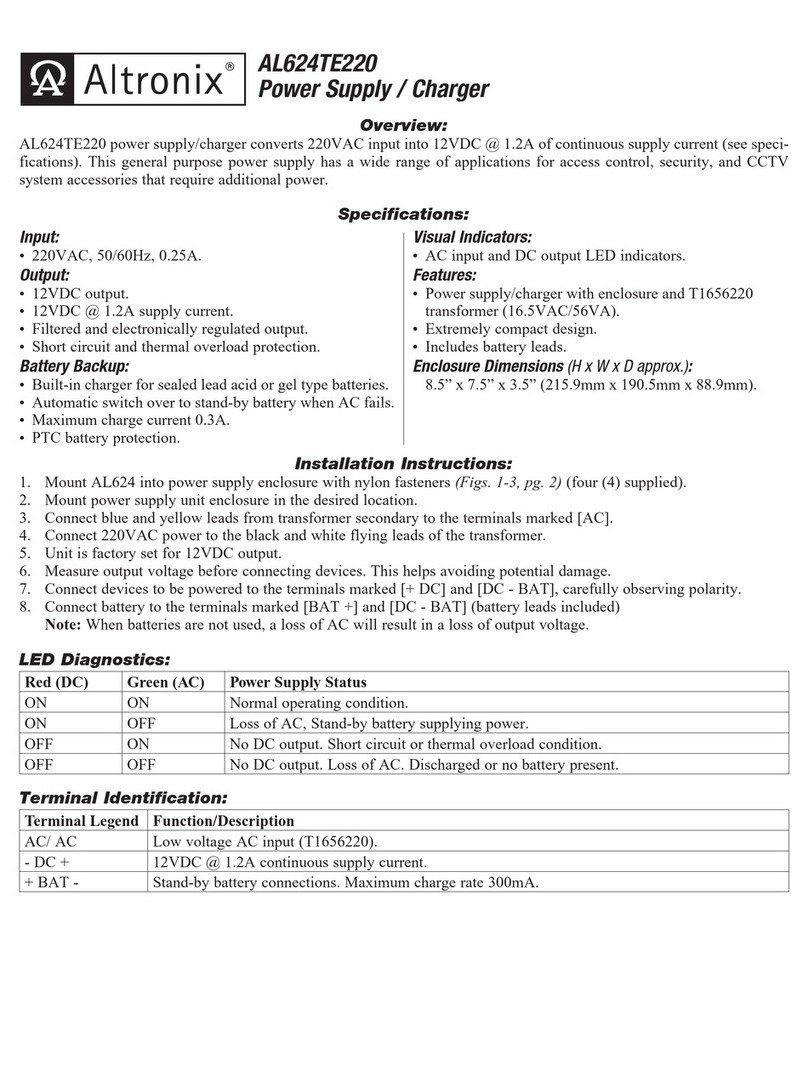

Altronix

Altronix AL624TE220 installation instructions

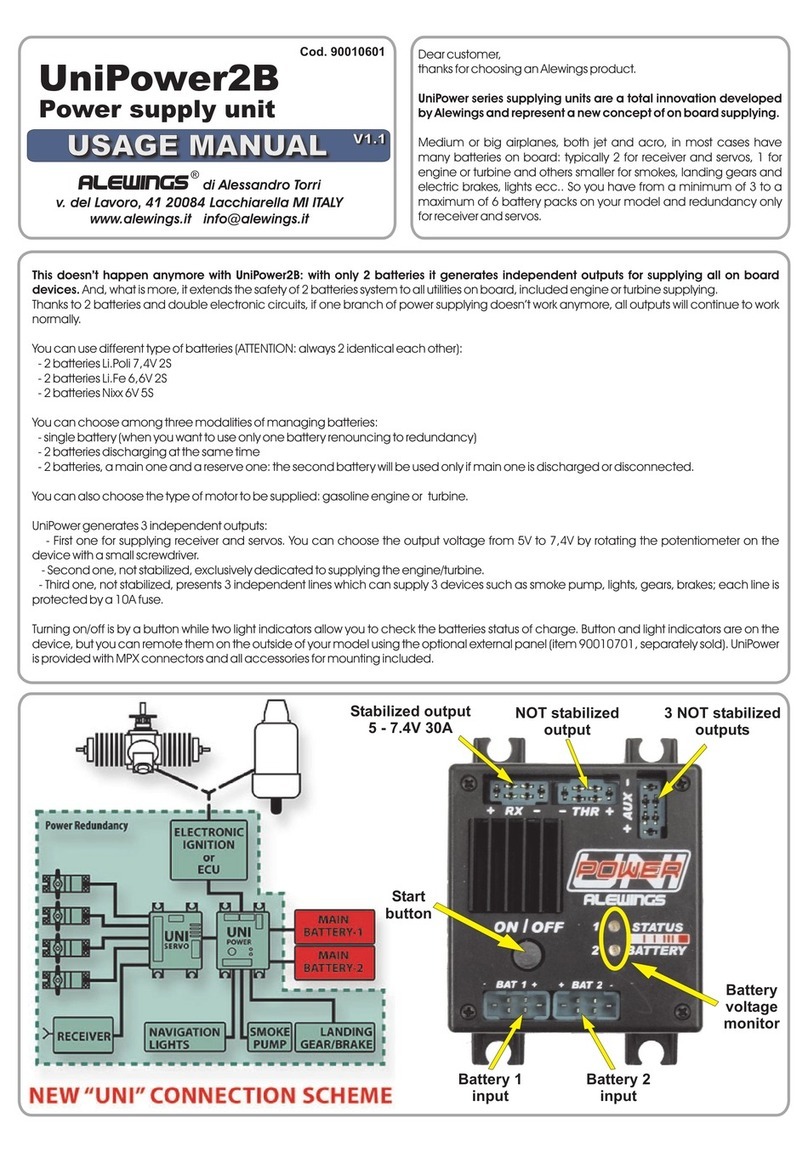

Alewings

Alewings UniPower2B Usage manual

Emerson

Emerson NetSure 501 A50 instruction manual

socomec

socomec SUNSYS PCS2 IM UL Series Installation and operating manual

TDK

TDK iHA48060A012V datasheet

Geno Technology

Geno Technology BT Lab Systems BT407 manual