English

1.0 INTRODUCTION

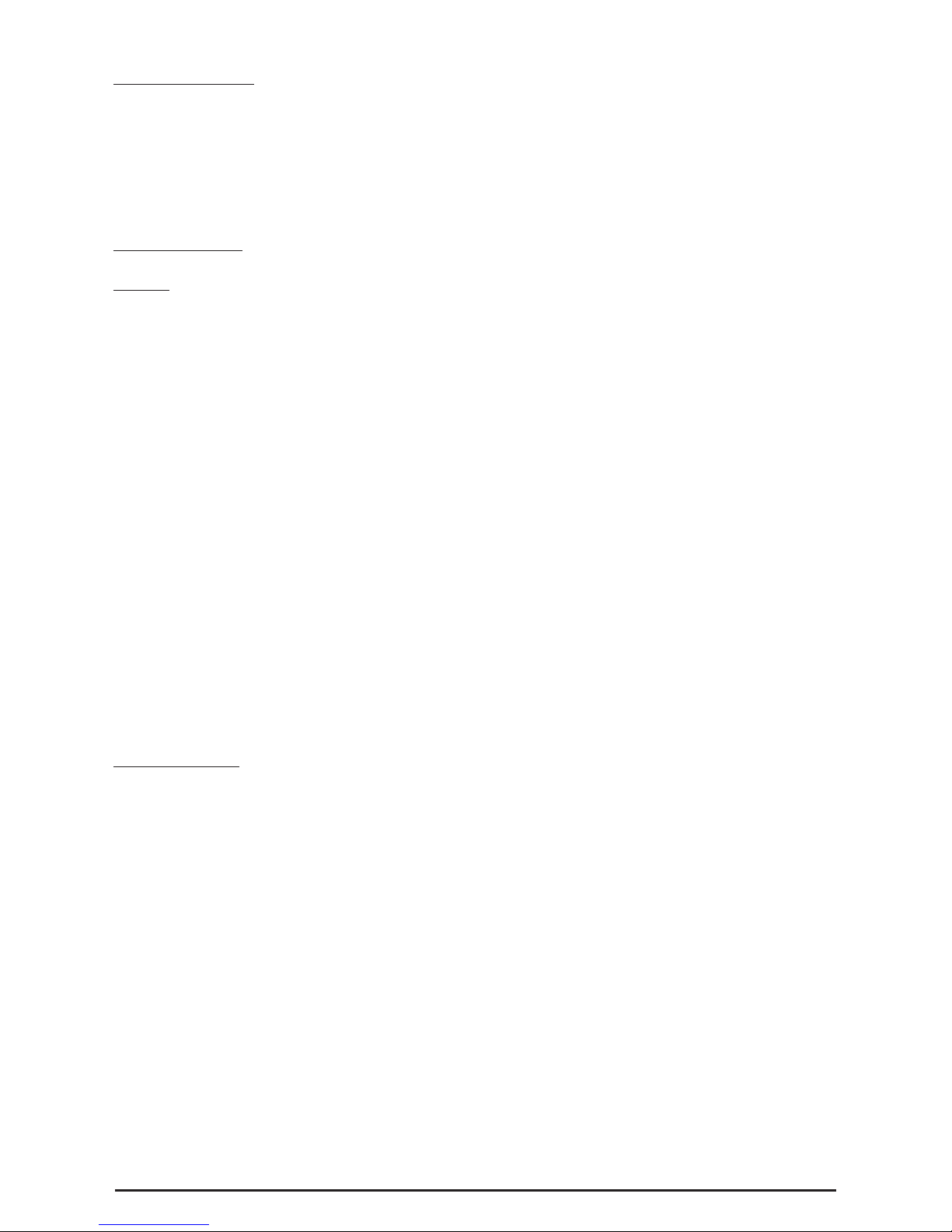

This range of light weight, flameproof sounders has been designed with a high weatherproof rating to cope with

the harsh environmental conditions found offshore and onshore in the oil, gas and petrochemical industries

New electronic circuitry allows the DB1 and DB1H to be switched between two user selectable tones by either

reversing the polarity, or connecting a second voltage supply (dual tone facility is available on dc units only).

The higher output DB1H is particularly suitable for noisy environments.

2.0 INSTALLATION

General

When installing and operating explosion-protected equipment, requirements for selection, installation and op-

eration should be referred to e.g. IEE Wiring Regulations and the ‘National Electrical Code’ in North America.

Additional national and/or local requirements may apply.

Ensure that all nuts, bolts and fixings are secure.

Ensure that only the correct listed or certified stopping plugs are used to blank off unused gland entry points

and that the NEMA/IP rating of the unit is maintained. MEDC recommend the use of a sealing compound such

as ‘HYLOMAR PL32’ on the threads of glands and stopping plugs in order to maintain the IP or NEMA rating

of the unit.

The sounder is mounted via the 2 off Ø9mm fixing holes. The fixing holes have been designed to accept an M8

screw or bolt.

MEDC recommend the use of stainless steel screws.

The unit has been designed and certified to operate at any attitude – from horizontal to vertical however, it is

important to note that the alignment of the sounder should ensure that:-

1. Dust or debris cannot lodge or settle in the re-entrant horn

2. Water from hoses, jets or rain cannot settle in the re-entrant horn

Cable Termination

CAUTION: Before removing the cover assembly, ensure that the power to the unit is isolated.

Unscrew the 4 off M6 screws (5.0mm A/F hexagon key) holding the cover assembly to the base. Keep screws

in a safe accessible place as they are not retained in the cover.

Before lifting the cover, gently twist the cover assembly clockwise then anti-clockwise to break the seal.

Continue to gently twist the cover clockwise and anti-clockwise while gently lifting the cover assembly away from

the base of the enclosure to gain access to the interior.

The cover assembly is connected to the cover by a nylon restraining strap to prevent loss.

Cable termination should be in accordance with specifications applying to the required application. MEDC

recommends that all cables and cores should be correctly identified. Please refer to the wiring diagram provided

with the product and see below for wiring options.

Ensure that only the correct listed or certified cable glands are used and that the assembly is shrouded and

correctly earthed.

All cable glands should be of an equivalent NEMA/IP rating to that of the unit and integrated with the unit such

that this rating is maintained.

The internal earth terminal, where fitted, must be used for the equipment grounding connection and the external

terminal is for a supplementary bonding connection where local codes or authorities permit or require such a

connection.

© Eaton MEDC Ltd 2018 01/18