EM-0489 Rev.2 P. 1 / 3

MG CO., LTD. www.mgco.jp

5-2-55 Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

INSTRUCTION MANUAL

CONTROL OUTPUT ISOLATOR MODEL 18KYC

BEFORE USE ....

Thank you for choosing us. Before use, please check con-

tents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact our sales office or representatives.

■PACKAGE INCLUDES:

Signal conditioner ...............................................................(1)

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

24V DC rating: 24V ±10%, approx. 50mA

■GENERAL PRECAUTIONS

• Before you remove the unit or mount it, turn off the power

supply and input signal for safety.

■ENVIRONMENT

• Indoor use.

• When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■WIRING

• Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

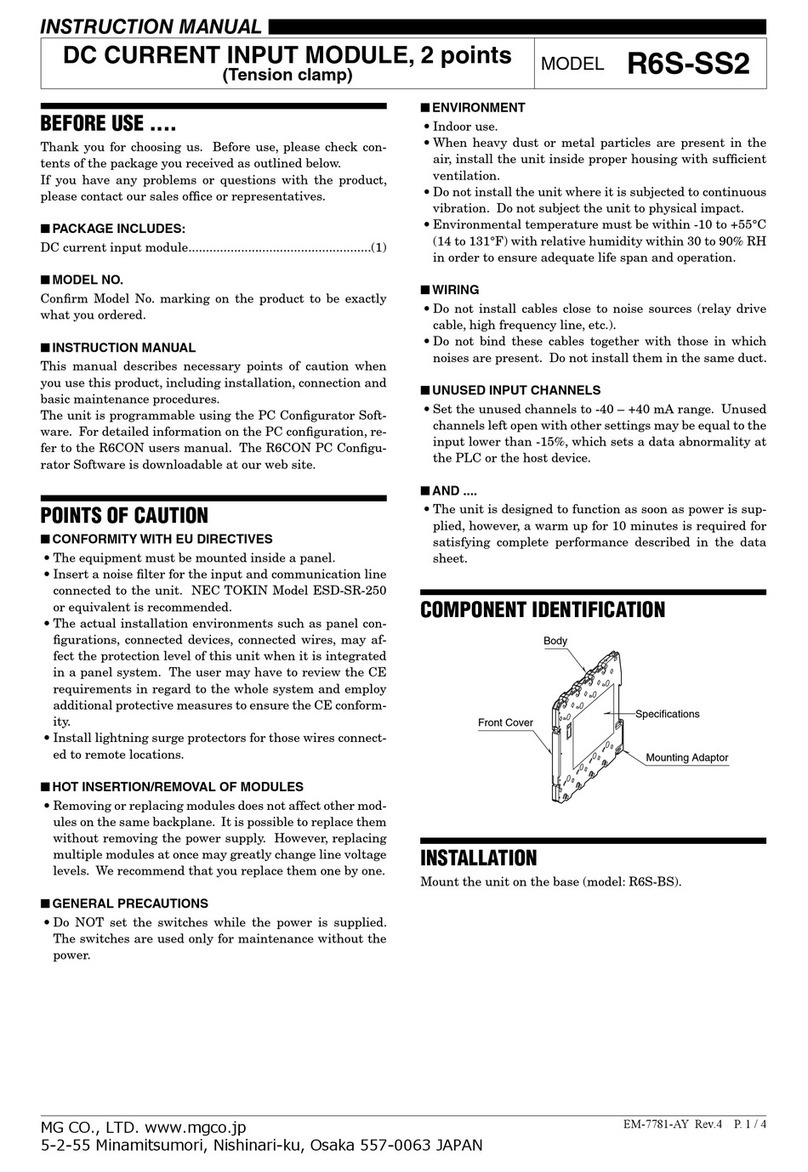

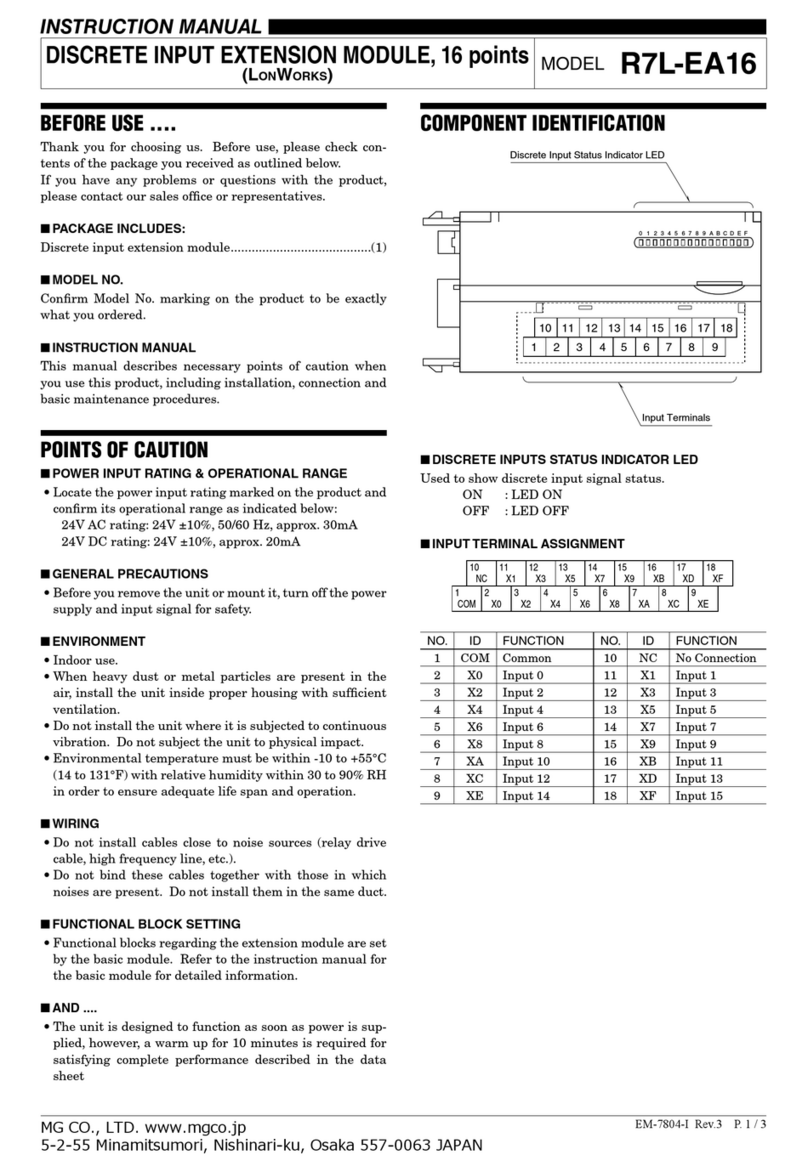

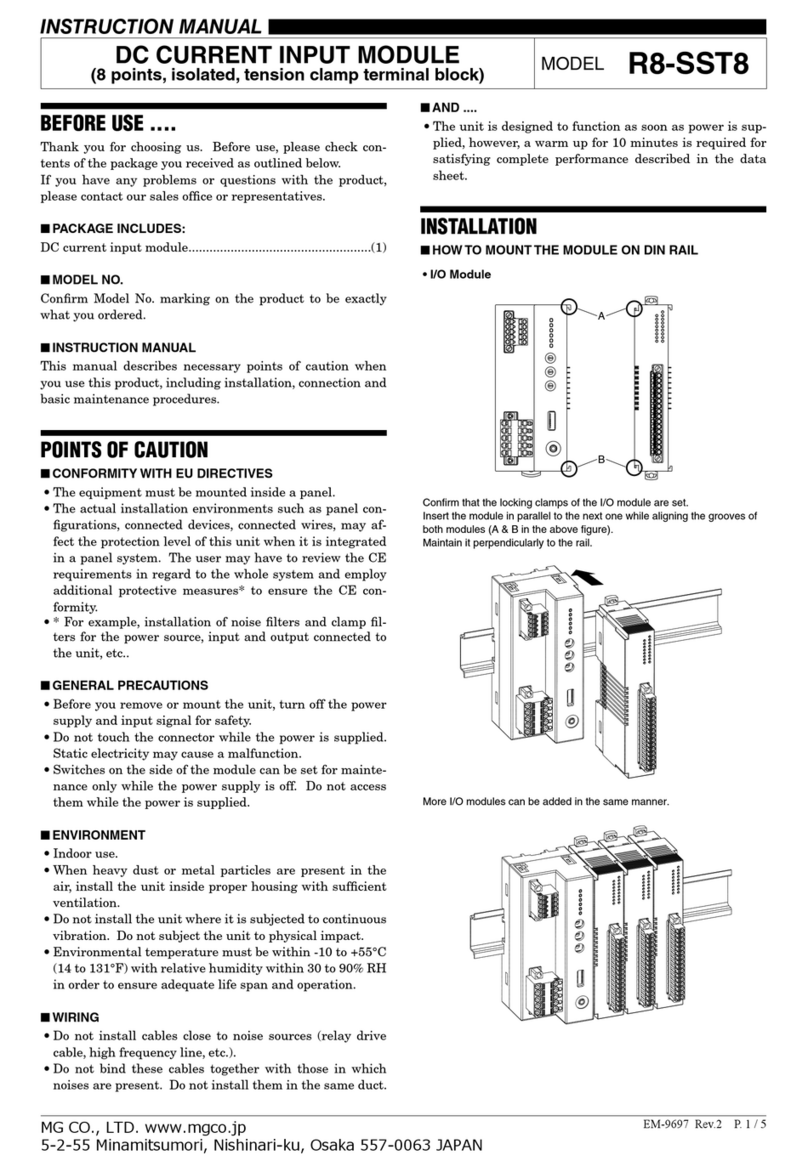

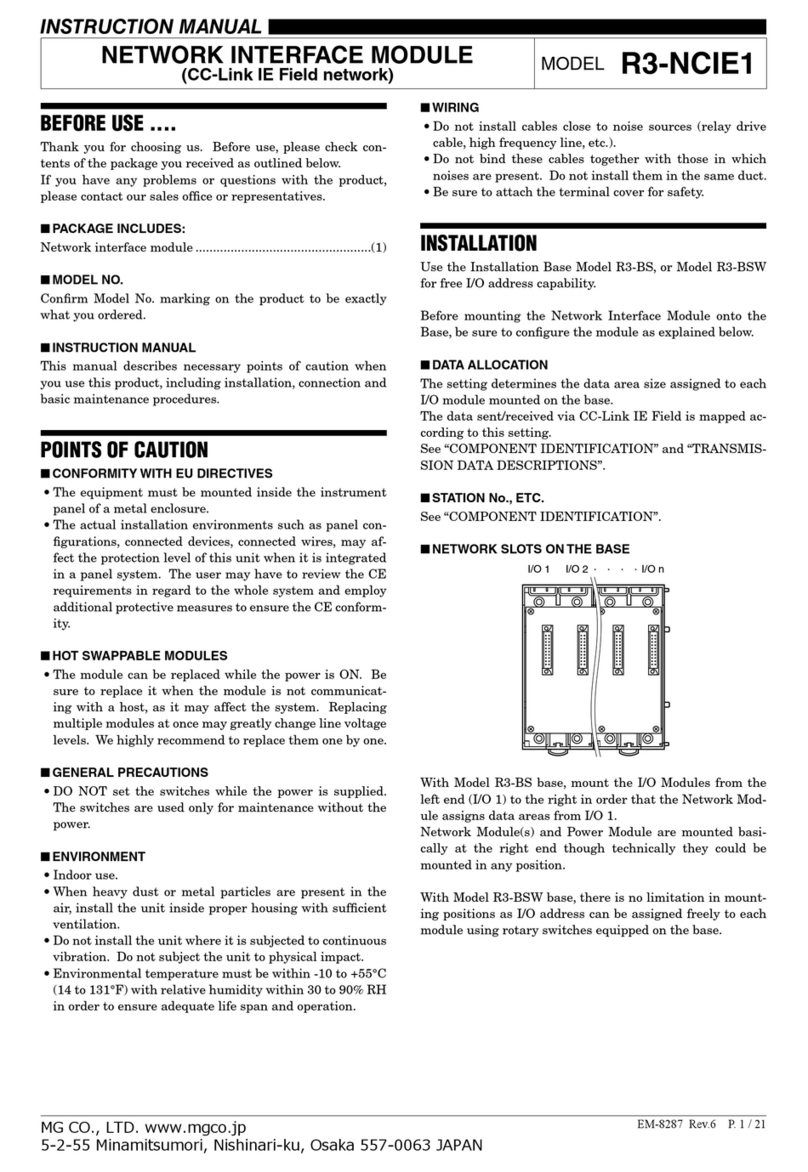

COMPONENT IDENTIFICATION

Body

Specifications

Front Cover

(Connection diagram

behind)

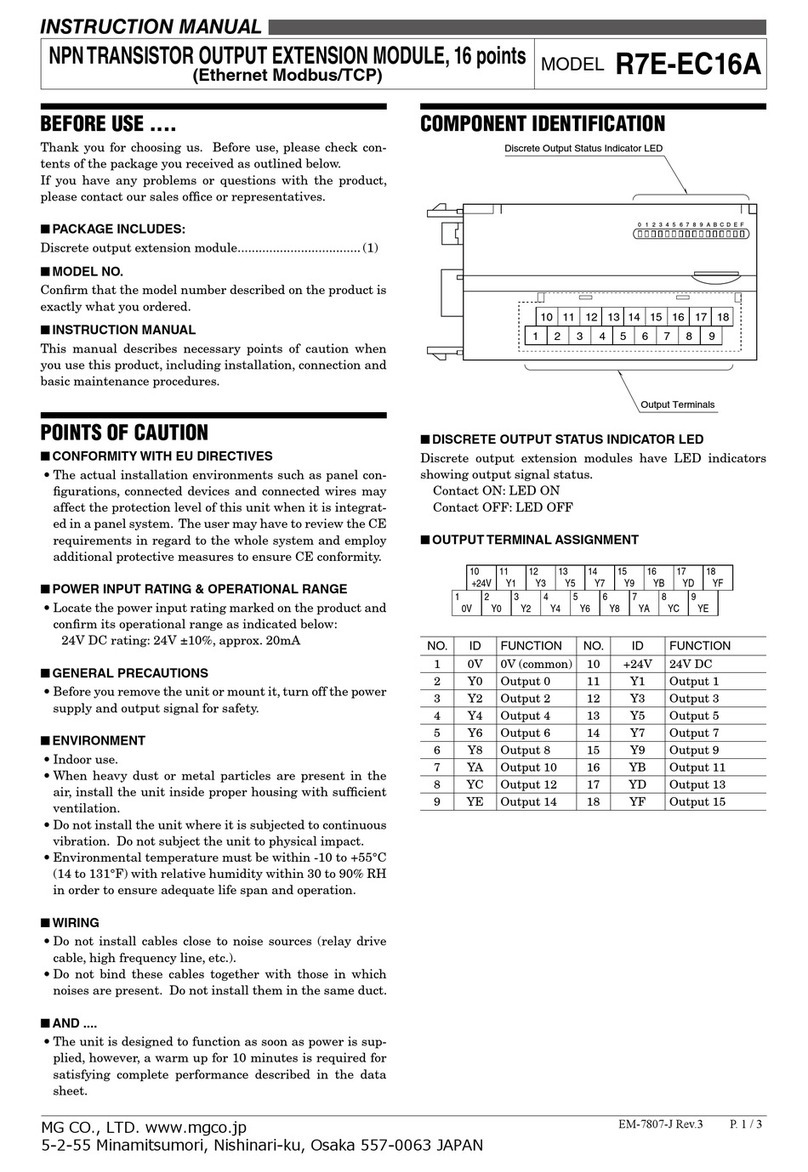

■FRONT VIEW (with cover open)

• Without Power Switch

Span Adj.

Zero Adj.

1

78

56

2

34

• With Power Switch

Power Switch

Span Adj.

Zero Adj.

1

78

56

2

34

ON

OFF

INSTALLATION

Use Standard Rack (model: 18KBXx).