The mainboard module also makes a calculation using the oximetry input signal; from this signal collected at a 16

msec/frequency the percentage value of oxygen saturation in the blood and the heart beat values are obtained, which are

oximetry parameters.

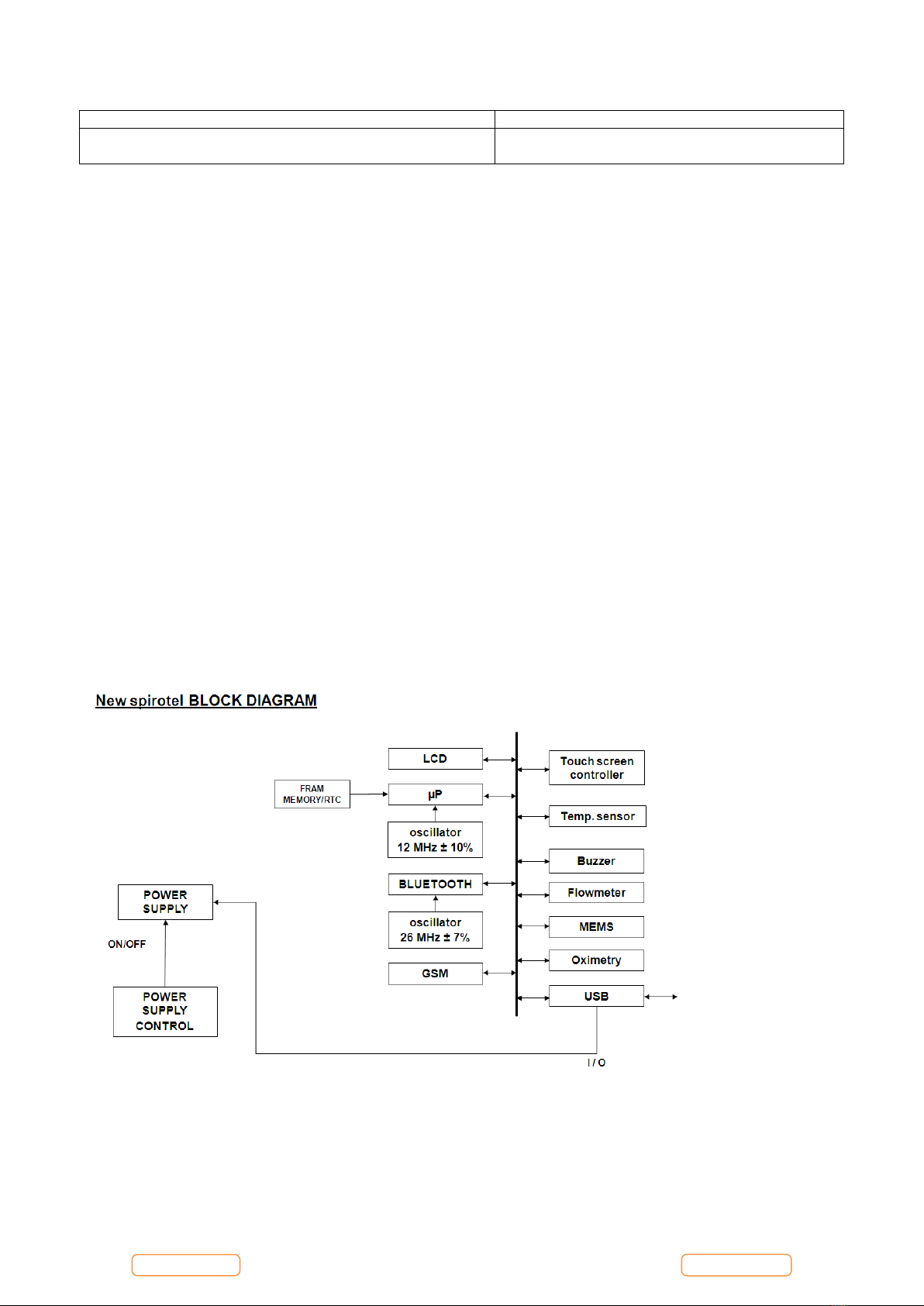

The mainboard module includes:

-Main Microcontroller

-FLASH memory with device configuration and spirometry data

-FRAM IC with non volatile memory and real time clock

-Measuring controller for flow, volume and ambient temperature

-Ambient temperature sensor (to enable conversion from ATP to BTPS conditions).

-USB port

-Oximetry port

-Bluetooth module

-GSM Module

2.1.1. Charging controller for battery pack (IC7 LTC 4067)

The charging controlling circuit used in the new spirotel ensures a charge and optimum condition of the battery pack

providing that the battery temperature and voltage are within the preset limits. Temperature, voltage and time are all

monitored throughout the charge process.

The charging process itself is automatically initiated in two situations:

1. After connecting the battery charger to the unit.

2. When the unit is switched on, the battery charger is connected and the voltage level of the battery is below a preset

limit. In this situation the LCD indicates the low battery status with one line in the battery indicator.

The fast charging process is terminated by any of the following:

-Battery voltage out of range (Maximum/Minimum)

-Battery temperature out of range (Maximum/Minimum)

-Maximum charging time (timeout = 2h after the voltage arrives at the maximum value, 4.2 V)

Charging phases:

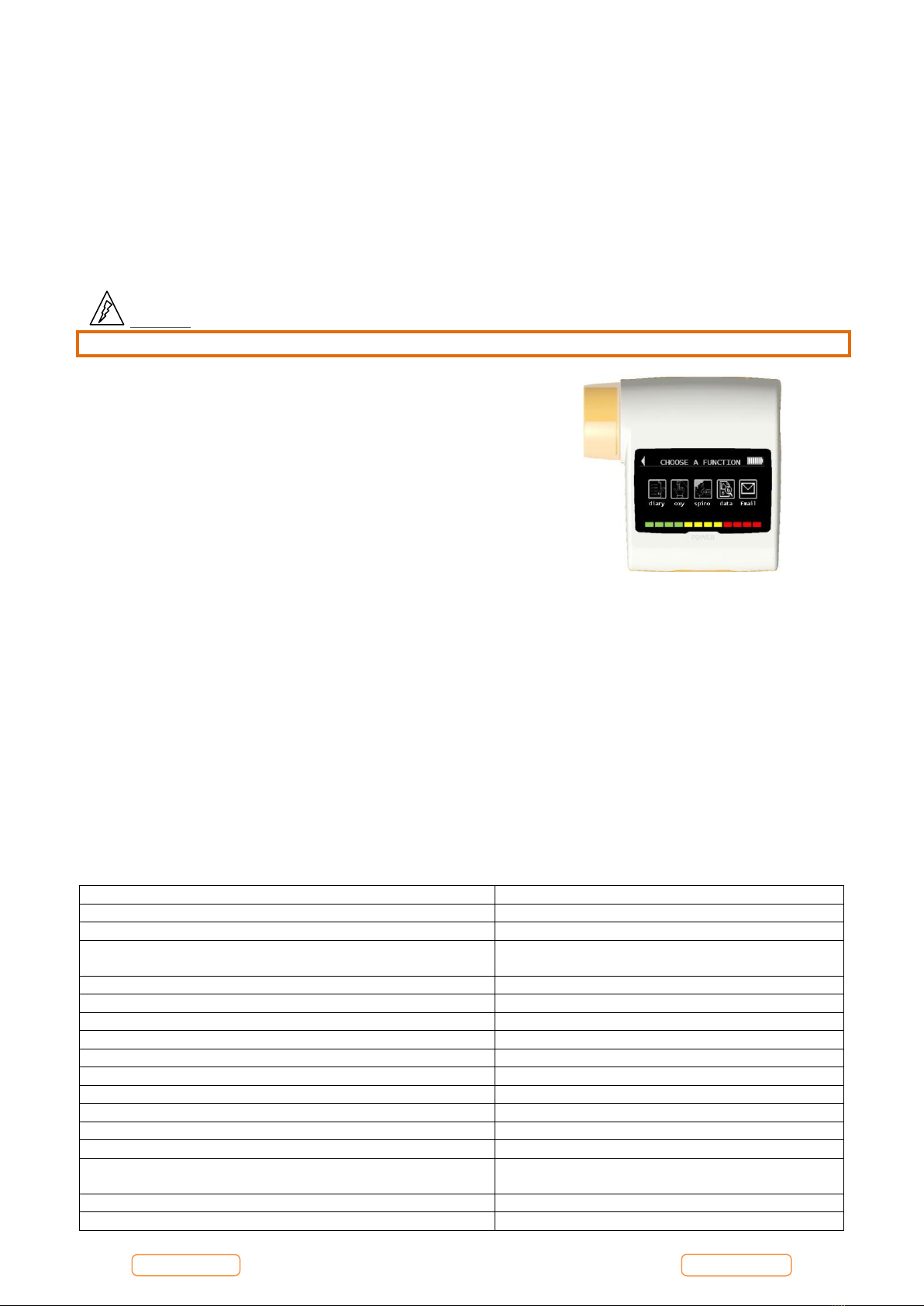

1. If everything is in order (battery temperature, temperature rising, battery voltage etc.) then the charging process starts

and the display shows the following image in the upper right

2. At the end of the regular charging process, the display shows the following message:

Battery full

3. If after completing the charging process the battery charger is still connected, a so-called Pulse-Trickle-Function is

activated that gives a very low charge to compensate the self-discharging of the battery while it is idle connected to the

charger.

2.1.2. Room temperature sensor

(IC6) DALLAS DS 18B20 to measure the ambient (room) temperature to enable the calculation of the BTPS conversion

factor.

2.1.3. USB communication port

Version 2.0.

2.1.4. Oximetry port

The connector beside the USB ports is used to connect the oximetry sensor, where this function is enabled on the device.

Many sensors can be used on new spirotel

based on the type of test to be performed and on the patient characteristics.

The manufacturer provides the most frequently used sensor with the device, which has the following features: