INDEX

1. INTRODUCTION..................................................................................................................................................................................................................3

1.1. INTRODUCTORY REMARKS .............................................................................................................................................................................................3

1.1.1. General Aspects..................................................................................................................................................................................................................3

1.1.2. Safety Aspects.....................................................................................................................................................................................................................3

1.1.3. Legal Aspects .....................................................................................................................................................................................................................3

1.1.4. Environmental Aspects...................................................................................................................................................................................................... 3

1.2. DATA REGISTRATION........................................................................................................................................................................................................4

1.2.1. Equipment and customer registration / Service file ........................................................................................................................................................4

1.2.2. Configuration register........................................................................................................................................................................................................4

1.2.3. Product documentation .....................................................................................................................................................................................................4

1.2.4. Technical modifications ....................................................................................................................................................................................................4

1.2.5. Product evaluation .............................................................................................................................................................................................................4

1.2.6. Additional Information ......................................................................................................................................................................................................5

1.2.7. Installation..........................................................................................................................................................................................................................5

1.3. GENERAL...............................................................................................................................................................................................................................5

1.3.1. Technical Data...................................................................................................................................................................................................................5

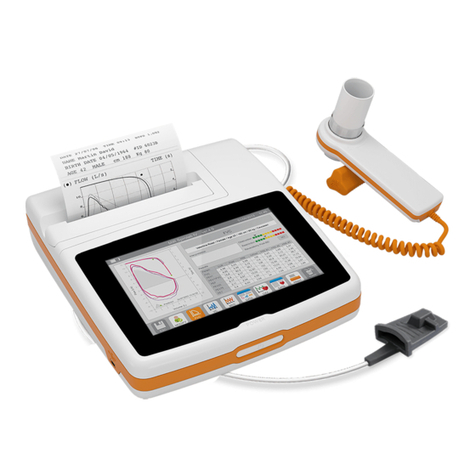

1.3.1.1. spirobank II unit ................................................................................................................................................................................................................5

1.3.1.2. Battery charger ...................................................................................................................................................................................................................6

1.4. STANDARDS APPLIED ........................................................................................................................................................................................................6

2. HARDWARE DESCRIPTION ..............................................................................................................................................................................................6

2.1. MAIN BOARD MODULE .....................................................................................................................................................................................................7

2.1.1. Charging controller for battery (IC1 LTC 4067) ..............................................................................................................................................................7

2.1.2. Room temperature sensor..................................................................................................................................................................................................8

2.1.3. USB communication port..................................................................................................................................................................................................8

2.1.4. Oximetry port .....................................................................................................................................................................................................................8

2.2. DISPLAY MODULE...............................................................................................................................................................................................................8

2.3. TURBINE FLOWMETER.....................................................................................................................................................................................................8

3. MAINTENANCE ...................................................................................................................................................................................................................9

3.1. GENERAL...............................................................................................................................................................................................................................9

3.2. TEST EQUIPMENT ..............................................................................................................................................................................................................9

3.3. CHECKLIST.......................................................................................................................................................................................................................... 10

3.3.1. Functional test.................................................................................................................................................................................................................. 10

3.3.1.1. Self test.............................................................................................................................................................................................................................. 10

3.3.1.2. Software version ............................................................................................................................................................................................................... 10

4. REPLACEMENT PROCEDURES ..................................................................................................................................................................................... 10

4.1. General ................................................................................................................................................................................................................................... 10

4.2. Cover........................................................................................................................................................................................................................................11

4.2.1. Opening the device ...........................................................................................................................................................................................................11

4.3. PCBs and components .......................................................................................................................................................................................................... 12

4.3.1. Removing and replacing the display............................................................................................................................................................................... 12

4.3.2. Removing and replacing the keyboard ........................................................................................................................................................................... 13

4.3.3. Removing and replacing the internal battery ................................................................................................................................................................. 13

4.3.4. Turbine............................................................................................................................................................................................................................. 16

4.3.4.1. Cleaning the reusable turbine.......................................................................................................................................................................................... 16

4.3.4.2. Calibration of the reusable turbine.................................................................................................................................................................................. 17

4.3.5. Internal software upgrade procedure .............................................................................................................................................................................. 17

4.4. Oximeter module ................................................................................................................................................................................................................... 18

4.4.1. Replacing of the oximetry module .................................................................................................................................................................................. 18

4.5. Testing procedures ................................................................................................................................................................................................................ 19

4.5.1. Testing procedures for devices with oximeter................................................................................................................................................................ 19

4.5.2. Testing procedures for devices without oximeter .......................................................................................................................................................... 23

5. SPARE PARTS....................................................................................................................................................................................................................... 25

5.1. ORDERING .......................................................................................................................................................................................................................... 25

5.2. DELIVERY............................................................................................................................................................................................................................ 25

5.2.1. Ordering PCB's................................................................................................................................................................................................................ 25

5.2.2. Warranty claims................................................................................................................................................................................................................ 25

5.3. RETURN SHIPMENTS ...................................................................................................................................................................................................... 25

6. TROUBLESHOOTING....................................................................................................................................................................................................... 26

6.1. The device does not switch on .............................................................................................................................................................................................. 26

6.2. The LCD does not display..................................................................................................................................................................................................... 26

6.3. The battery is not working correctly .................................................................................................................................................................................... 26

6.4. The device does not measure spirometry at all .................................................................................................................................................................... 27

6.5. The device does not measure spirometry correctly.............................................................................................................................................................. 27

6.6. The device does not measure oximetry at all ....................................................................................................................................................................... 27

6.7. The device does not measure oximetry correctly ................................................................................................................................................................. 27

6.8. The data communication via USB does not function .......................................................................................................................................................... 27

6.9. Index of components ............................................................................................................................................................................................................. 28

APPENDIX A: SPARE PARTS LIST .............................................................................................................................................................................................. 29

APPENDIX B: SERVICE INFO'S (Product Change Notes) ........................................................................................................................................................ 32

APPENDIX C.................................................................................................................................................................................................................................... 33

ANNEX.............................................................................................................................................................................................................................................. 35