Printed in Japan

Mitutoyo Corporation 1-20-1 Sakado, Takatsu-ku, Kawasaki City, Kanagawa 213-8533

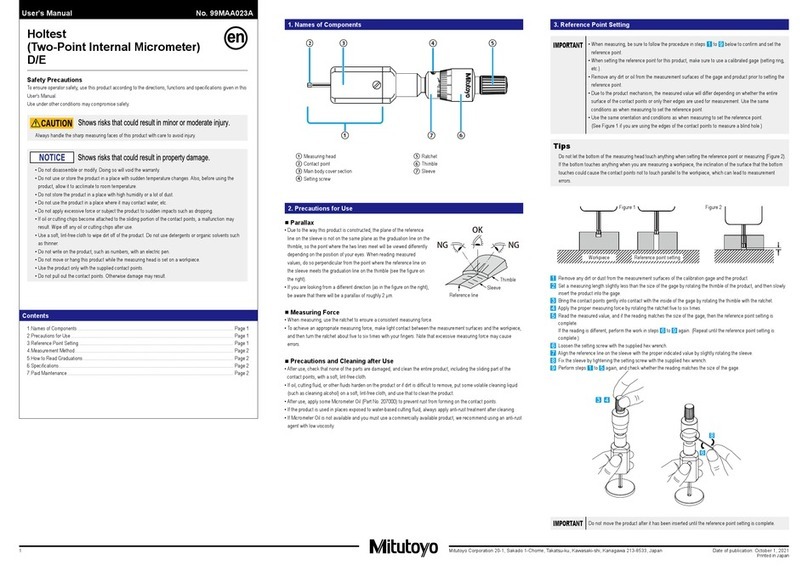

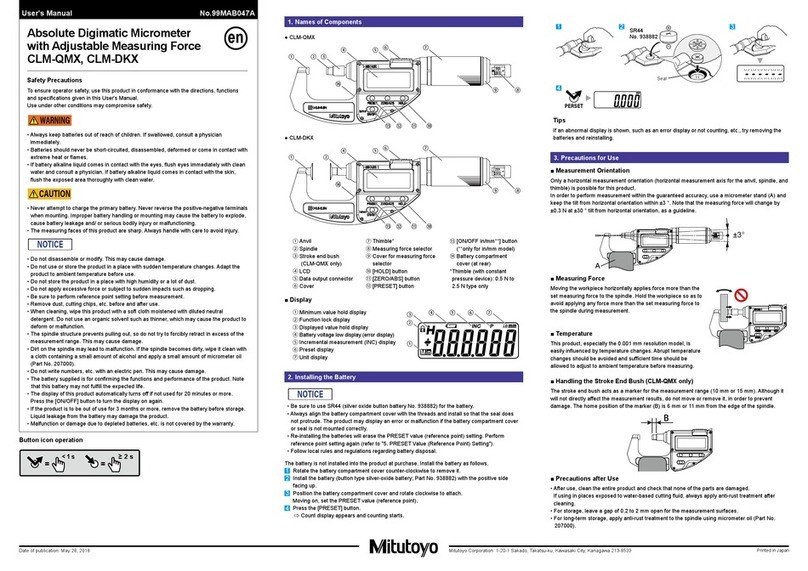

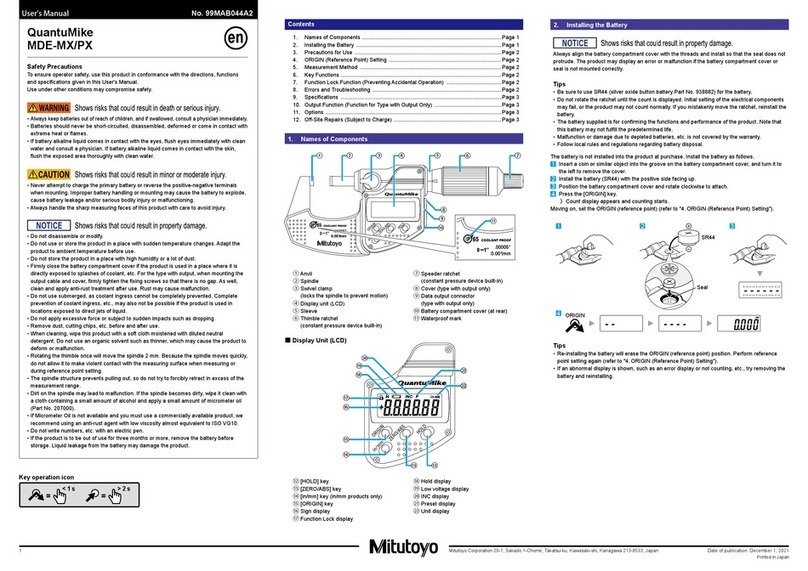

1. Names of Components

②

⑪

①

⑫

⑥

④③ ⑤

⑨⑩ ⑧ ⑦

①Anvil

②Spindle

③LCD

④Data output connector

⑤Cover

⑥Thimble (ratchet friction

type)

⑦[HOLD] button

⑧[ZERO/ABS] button

⑨[ORIGIN] button

⑩[ON/OFF in/mm*] button

(*only for in/mm model)

⑪Battery compartment

cover (at rear)

⑫Waterproof mark

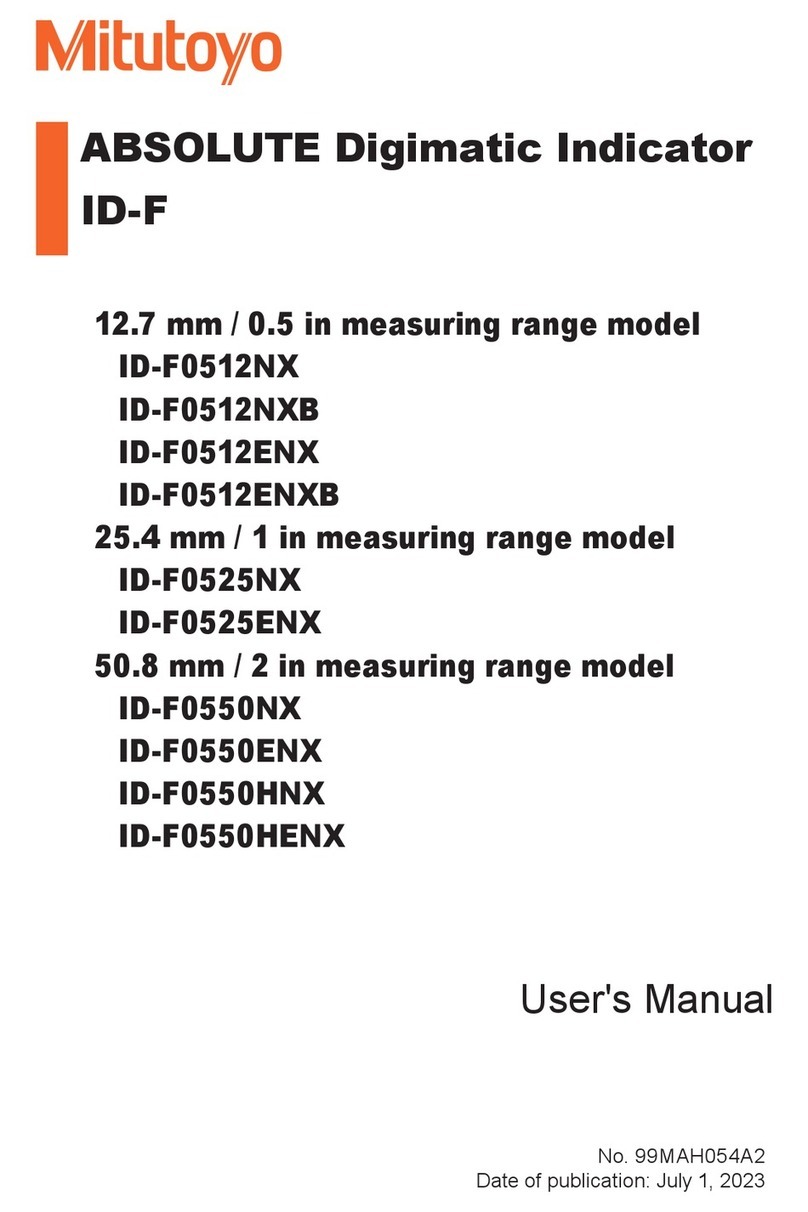

■ Display

①Minimum value hold display

②Function lock display

③Displayed value hold display

④Battery voltage low display (error display)

⑤Incremental measurement (INC) display

⑥Preset display

⑦Unit display

2. Installing the Battery

• Be sure to use SR44 (silver oxide button battery No. 938882) for the battery.

• Always align the battery compartment cover with the threads and install so that the seal does

not protrude. The product may display an error or malfunction if the battery compartment cover

or seal is not mounted correctly.

• Re-installing the batteries will erase the ORIGIN (reference point) position. Perform reference

point setting again (refer to "4. ORIGIN (Reference Point) Setting").

• Follow local rules and regulations regarding battery disposal.

The battery is not installed into the product at purchase. Install the battery as follows.

1Rotate the battery compartment cover counter-clockwise to remove it.

2Install the battery (button type silver-oxide battery; Part No. 938882) with the positive side facing up.

3Position the battery compartment cover and rotate clockwise to attach.

Moving on, set the ORIGIN (reference point).

4Press the [ORIGIN] button.

⇨ Count display appears and counting starts.

SR44

No. 938882

1 2 3

4

ORIGIN

Seal

Tips

If an abnormal display is shown, such as an error display or not counting, etc., try removing the

batteries and reinstalling.

③⑤ ⑥ ⑦

②

①

④

3. Precautions for Use

■ Measuring Force

• Be sure to use the thimble to apply a constant measuring force

when making measurements.

The appropriate measuring force is achieved with the following

procedure: make light contact between the measurement surfaces

and the workpiece, stop momentarily, and then manually turn the

thimble about three to ve times.

• Removing the workpiece from the measurement surfaces while measuring force is applied will

cause the spindle to advance and the measured value to change. Always read the measured

value while the workpiece remains clamped.

Hold the workpiece to stabilize measured values. If the workpiece moves, the measuring force will

change, introducing variations in the displayed value.

■ Temperature

This product, especially the 0.001 mm resolution model, is easily inuenced by temperature

changes. Abrupt temperature changes should be avoided and sufcient time should be allowed to

adjust to ambient temperature before measuring.

■ Precautions after Use

• After use, clean the entire product and check that none of the parts are damaged.

If using in places exposed to water-based cutting uid, always apply anti-rust treatment after cleaning.

• For storage, leave a gap of 0.2 to 2 mm open for the measurement surfaces.

• For long-term storage, apply anti-rust treatment to the spindle using micrometer oil (Part No. 207000).

4. ORIGIN (Reference Point) Setting

• For reference point setting, use a periodically inspected reference gage (gauge block,

micrometer standard bar, etc.).

• Reference point setting and measurement should be made in the same orientation and

conditions and with the procedure as below.

• If the reference point changes due to temperature changes, recongure the ORIGIN.

■ ORIGIN (Reference Point) Setting

1Clean both anvil and spindle measurement surfaces, together with the micrometer standard bar

if it is used to remove all debris or dust.

2For 0 to 30 mm measurement range:

After making light contact with both measurement surfaces, stop momentarily, and then apply

the appropriate measuring force (Refer to "3. Precautions for Use ■ Measuring Force").

For outside the 0 to 30 mm measurement range:

After the spindle makes light contact with the standard bar sandwiched between the

measurement surfaces, stop momentarily, and then apply the appropriate measuring force

(Refer to "3. Precautions for Use ■ Measuring Force").

3Press the [ORIGIN] button.

⇨Check that [P] is blinking and the ORIGIN (reference point) value* is displayed

(*Refer to "Tips" on the following page).

4Press the [ORIGIN] button again.

⇨[P] turns off and the ORIGIN (reference point) value is set.

• For 0 to 30 mm measurement range:

2

1 3 4

ORIGIN ORIGIN

• For above the 0 to 30 mm measurement range (e.g., 25 to 55 mm):

Turn approximately

three to ve times.

2

13 4

ORIGIN ORIGIN

Safety Precautions

To ensure operator safety, use this product in conformance with the directions, functions

and specications given in this User's Manual.

Use under other conditions may compromise safety.

• Always keep batteries out of reach of children. If swallowed, consult a physician

immediately.

• Batteries should never be short-circuited, disassembled, deformed or come in contact with

extreme heat or ames.

• If battery alkaline liquid comes in contact with the eyes, ush eyes immediately with clean

water and consult a physician. If battery alkaline liquid comes in contact with the skin,

ush the exposed area thoroughly with clean water.

• Never attempt to charge the primary battery. Never reverse the positive-negative terminals

when mounting. Improper battery handling or mounting may cause the battery to explode,

cause battery leakage and/ or serious bodily injury or malfunctioning.

• The measuring faces of this product are sharp. Always handle with care to avoid injury.

• Do not disassemble or modify. This may cause damage.

• Do not use or store the product in a place with sudden temperature changes. Adapt the

product to room temperature before use.

• Do not store the product in a place with high humidity or a lot of dust.

• Firmly close the battery compartment cover if the product is used in a place where it is

directly exposed to splashes of coolant, etc. When mounting the output cable and cover,

rmly tighten the mounting screws so that there is no gap. As well, apply anti-rust

treatment after use. Rust may cause malfunction.

• Do not use even waterproof types submerged, as coolant ingress cannot be completely

prevented. Complete prevention of coolant ingress, etc., may also not be possible if the

product is used in locations exposed to direct jets of liquid.

• Do not apply excessive force or subject to sudden impacts such as dropping.

• Be sure to perform reference point setting before measurement.

• Remove dust, cutting chips, etc. before and after use.

• When cleaning, wipe this product with a soft cloth moistened with diluted neutral

detergent. Do not use an organic solvent such as thinner, which may cause the product to

deform or malfunction.

• The spindle structure prevents pulling out, so do not try to forcibly retract in excess of the

measurement range. This may cause damage.

• Dirt on the spindle may lead to malfunction. If the spindle becomes dirty, wipe it clean with

a cloth containing a small amount of alcohol and apply a small amount of micrometer oil

(Part No. 207000).

• Do not write numbers, etc. with an electric pen. This may cause damage.

• The display of this product automatically turns off if not used for 20 minutes or more. Press

the [ON/OFF] button to turn the display on again.

• The battery supplied is for conrming the functions and performance of the product. Note

that this battery may not fulll the expected life.

• If the product is to be out of use for 3 months or more, remove the battery before storage.

Liquid leakage from the battery may damage the product.

• Malfunction or damage due to depleted batteries, etc. is not covered by the warranty.

Quickmike MDQ

User's Manual No.99MAB046A

Button icon operation

=

≥ 2 s

=

< 1 s

Date of publication: May 28, 2018