Ⅶ、Working procedure

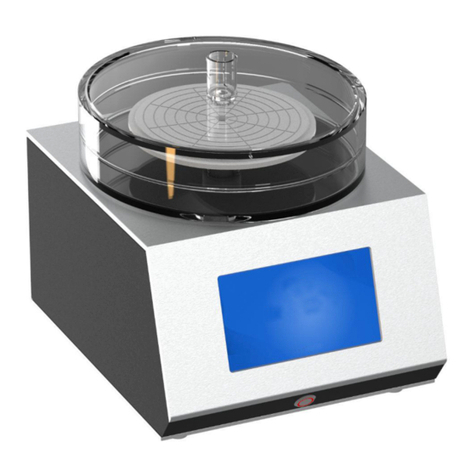

1) the centrifuge placed on the platform, visual to balance, shake and check whether the

centrifuge placed smoothly.

2) confirm the placement is stable, turn on the power, press the power switch, press the "stop

/ open" button, the lid can be opened.

3) Open the lid, the selected rotor gently placed on the motor shaft, screw on the screw so

that the rotor and the motor shaft tightly connected together (Note: it should be careful

and gentle, to avoid shaking and pull up and down, so as not to Damage the motor

support), and then put the tube set or adapter on the rotor, complete gently turn the rotor,

the rotor should be flexible rotation, Tube set (adapter) on the rotor should be tilted freely,

no block and rub Touch the phenomenon.

4) Put the tube filled with the same amount of test solution symmetrical into the tube set to

ensure that the rotor balance operation.

5) close the lid and check whether it has been locked (closed gently lift the lid, the lid is not

open. If the lid is not closed, press the "Start", the "time display" window will display "

E3 ").

6) set the rotor number, speed, time and other operating parameters.

(1)Set the speed: press the "Set" key, move the cursor to the "speed setting" position,

when the speed digital flicker, that is, enter the speed setting, then press the "increase

key" or "reduce key" to set the speed of this operation, after setting, press the

confirmation key to confirm the parameters.

Special reminder: The horizontal rotors and different adapters of this machine have their

own rotor numbers and maximum speed limits. Users must strictly observe the speed

limits of the rotor parameters when setting the speed parameters. Overspeed operation is

strictly prohibited to ensure safe operation.

(2)RCF set:Press“Set”to move the cusrsor to“Speed indicator”, when flashing,it is speed &

RCF switching state,Press“+”or“-” Switch the speed to RCF, “RCF”indicator,Press“Set”

move to,“Speed/RCF set”,when flashing,Press“+”or“-” to set and press “Enter” confirm

(3)Time:press“Set” to move the cursor to“Time Set”, when flashing,Press "+" or "-" to time

set,then press“Enter” confirm.

(4)Acc/Dec Set:press“Set” to move the cursor to“Acc” or “Dec”, when flashing,Press "+"

or "-" to acc/Dec set,then press“Enter”to confirm.

The system supports 0- 9 a total of 10 files, 0 is the fastest, 9 is the slowest, when the