1

Content

1 GENERAL............................................................................................................................. 3

1.1 INTRODUCTION ....................................................................................................................3

1.2 SAFETY................................................................................................................................3

1.2.1 User’s Qualification ........................................................................................................3

1.2.2 Proper Use ......................................................................................................................3

1.2.3 Improper Use ..................................................................................................................3

1.2.4 Warning Signs.................................................................................................................4

1.2.5 Hazards Related to the Instrument..................................................................................5

1.2.6 Other Hazards .................................................................................................................6

1.2.7 Safety Measures..............................................................................................................6

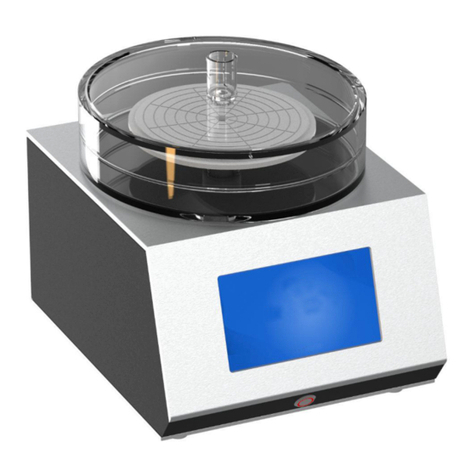

1.3 INSTRUMENT SYNOPSIS .......................................................................................................6

1.4 INSTRUMENT CONFIGURATION....................................................................................................7

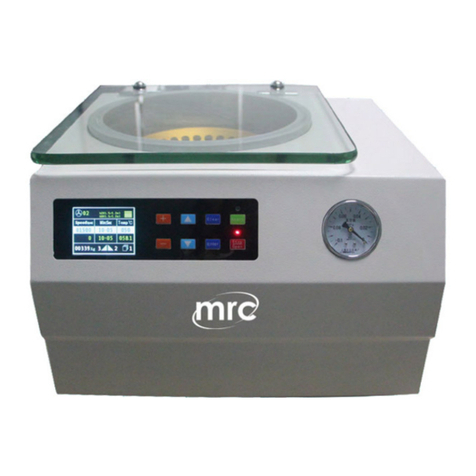

1.4.1 COT-2000H Configuration..............................................................................................7

1.4.2 COT-5000H Configuration..............................................................................................7

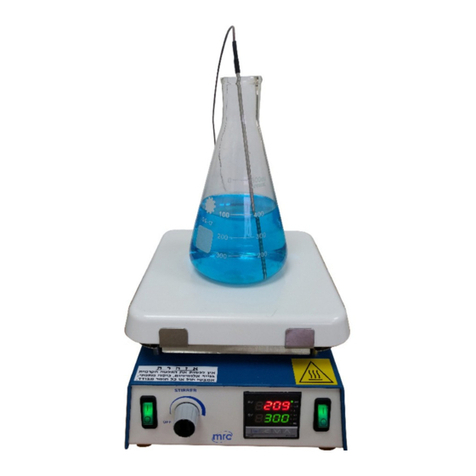

1.4.3 COT-2000L Configuration ..............................................................................................8

1.4.4 COT-5000L Configuration ..............................................................................................8

1.5 CONTROL PANEL INSTRUCTION............................................................................................9

1.5.1 COT-2000H、COT-5000H Control Panel Instruction.......................................................9

1.5.2 COT-2000L、COT-5000L Control Panel Instruction........................................................9

2UNPACKINGAND INSTALLATION.............................................................................. 10

3 TECHNICAL SPECIFICATIONS.................................................................................... 11

4. OPERATION.................................................................................................................... 12

4.1 POWER CONNECTION.........................................................................................................12

4.2 POWER ON .........................................................................................................................12

4.2.1 Close Breaker................................................................................................................12

4.2.2 Power Wwitch...............................................................................................................12

4.3 START REFRIGERATION SYSTEM ........................................................................................13

4.3.1 Start Refrigeration System at -40℃..............................................................................13

4.3.2 Start Refrigeration System at -80℃..............................................................................13

4.4 DRAIN ......................................................................................................................................13

4.5 POWER OFF ..............................................................................................................................14

5 PROTECTION FUNCTION............................................................................................... 14

6 MAINTENANCE AND MANAGEMENT.......................................................................... 14

6.1 MANAGEMENT...................................................................................................................14