2 Preventive Care

These actions are described in the operating manual supplied with each helmet and must be performed by the

helmet user at the prescribed frequency.

2.1 Routine Inspection

WARNING!

• Helmet absorbs the energy of a blow by partial destruction of, or damage to, the helmet. Even though such

damage may not be readily apparent, any helmet subjected to a severe impact should be replaced.

• Do not drop the helmet. Avoid unnecessary impacts to the helmet which could damage the face shield and/or

optional visor (cracks/scratches).

• In case of visible damage identified during the daily check (before or after use), such as impacts, significant

scratches, coating removal on the shell or visors, melted parts, broken parts, torn straps or paddings, missing

components, non-operational moving parts (such as visors or ratchet), etc., the helmet should be taken to the

trained maintenance technician or an MSA approved maintenance center for complete control processing.

• Do not use a helmet that has damage.

• Do not attempt to test the helmet. The performance properties of the helmet and its components cannot be

properly tested by a user in the field.

• Do not apply paint, adhesives or self-adhesives labels, cleaning products with a hydrocarbon base or solvents

to the helmet or visors to prevent damaging the materials of your helmet.

• Inspection and Maintenance operation listed in this manual must be performed only by personnel who have

been trained and certified by MSA.

• Use only MSA-approved parts. Do not alter, modify or substitute parts without the approval of MSA. Do not

deviate from the maintenance and repair procedures contained herein unless approved in writing by MSA.

• Failure to follow the recommended inspection procedures can reduce helmet performance and result in

serious personal injury, disease, illness, or death.

Failure to follow these warnings can result in serious personal injury or death.

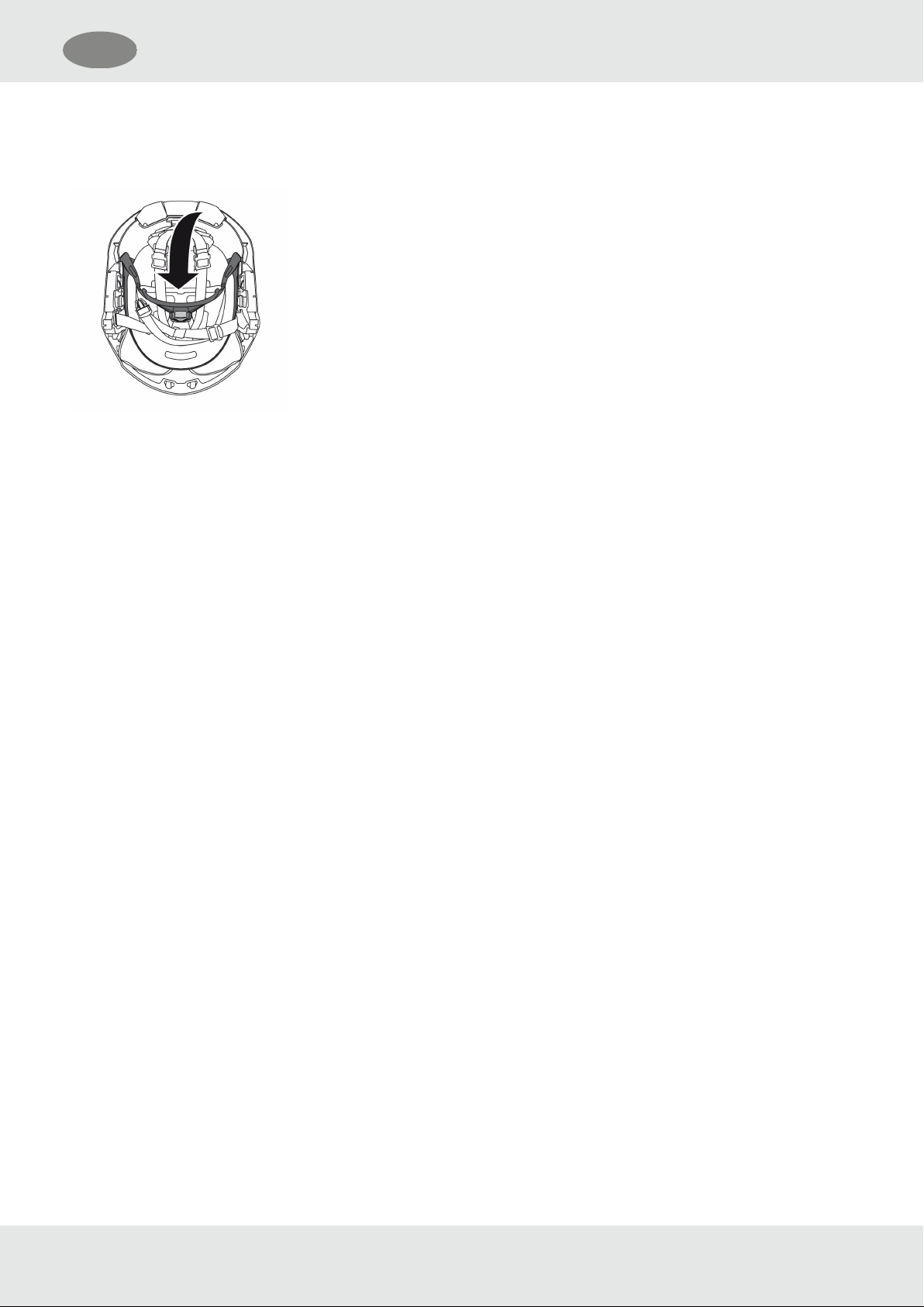

Before each use, inspect the helmet for visible damages such as:

• Cracks, breakages, major plastic distorsion (bumps) on shell, visors and all solid elements.

• Damaged straps or fabric elements (holes, torn areas, missing stitches, etc.).

• Proper attachment of the helmet’s components (chinstrap, suspension, interfaces) to the shell.

Check proper operation of adjustment and safety elements such as the headband ratchet knob, chinstrap buckle,

straps adjusters, etc.

If in doubt, do not use the helmet and request an advanced inspection or replacement of the damaged components.

5 GALLET F2XR

GB 2 Preventive Care