4

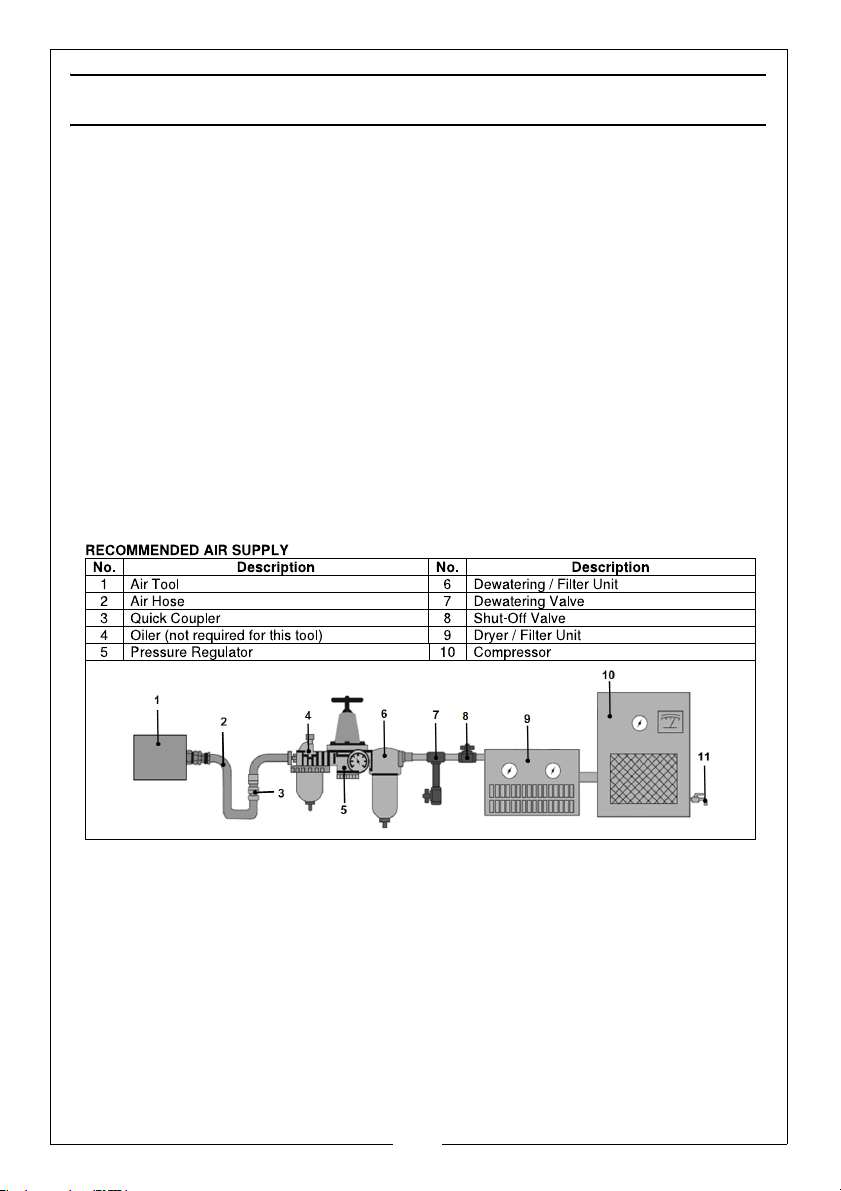

GENERAL SAFETY RULES

1. Read this instruction manual before connecting the sandblaster to a

compressor.

2. Do not use any silica based abrasives with this tool. Silica based abrasives

have been linked to severe respiratory disease. Always use recommended

abrasives. Abrasives used in this unit may be covered by COSHH

Regulations.

3. Read this manual carefully, Learn the tool's applications and limitations, as

well as potential hazards specific to it.

4. Do not expose tool to moisture. Don't use this tool in damp or wet locations,

Keep out of rain.

5. Keep work area clean and well lit. Cluttered or dark work areas invite

accidents,

6. Keep children away. All children should be kept away from the work area.

Never let a child handle a tool without strict adult supervision.

7. Do not operate this tool if under the influence of alcohol or drugs. Read

warning labels on prescriptions to determine if your judgment or reflexes

are impaired while taking drugs. If there is any doubt, do not attempt to

operate,

8. Use safety equipment. Dust mask, non-skid safety shoes, hard hat, or

hearing protection should be used in appropriate conditions.

9. Don't overreach, Keep proper footing and balance at all times when

operating this product.

10. Always disconnect the tool from the air supply and release pressure from

the tank before storing, servicing, or changing accessories.

11. Use clamps or other practical means to secure and support the work piece

to a stable platform. Do not hold the work by hand or against your body.

12. Do not point the sandblaster at anyone or any objects other than the

intended work object.

13. Check your sandblaster regularly for damage, If part of the sandblaster is

damaged it should be carefully inspected to make sure that it can perform

its intended function correctly. If in doubt, the part should be repaired.

Refer all servicing to a qualified technician. Consult your dealer for advice.

14. Do not attempt to operate this tool near flammable materials or

combustibles. Failure to comply may cause serious injury.

Warning: Compressed air can be dangerous. This machine is supposed to

be operated by pre-training.Ensure that you are thoroughly familiar with

all precautions relating to the use of compressors and compressed air

supply.Only professionals could use this equipment.