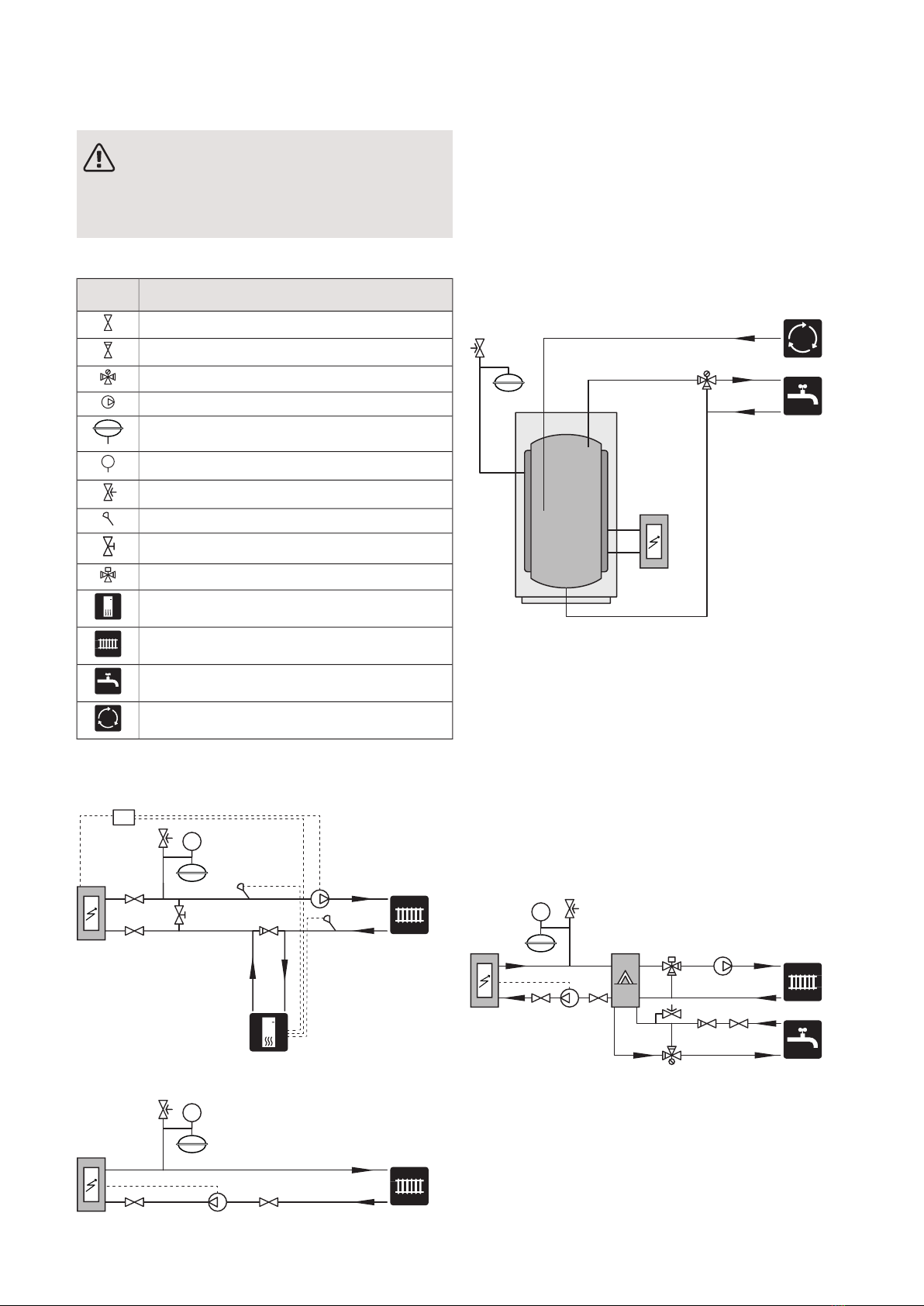

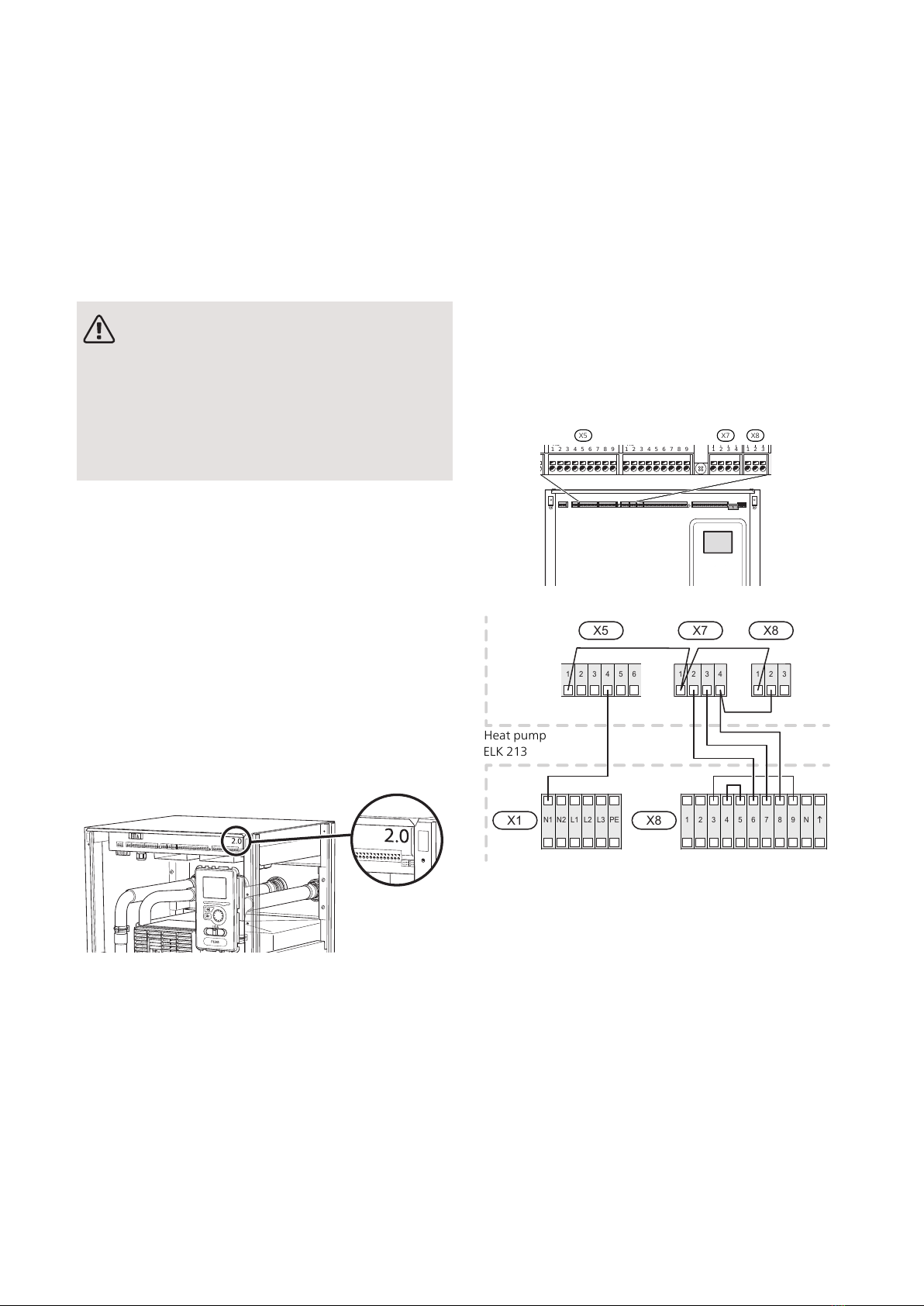

Nibe ELK 213 User guide

Other Nibe Heater manuals

Nibe

Nibe Drazice PTO 3.5 User manual

Nibe

Nibe EAH 20-900 User guide

Nibe

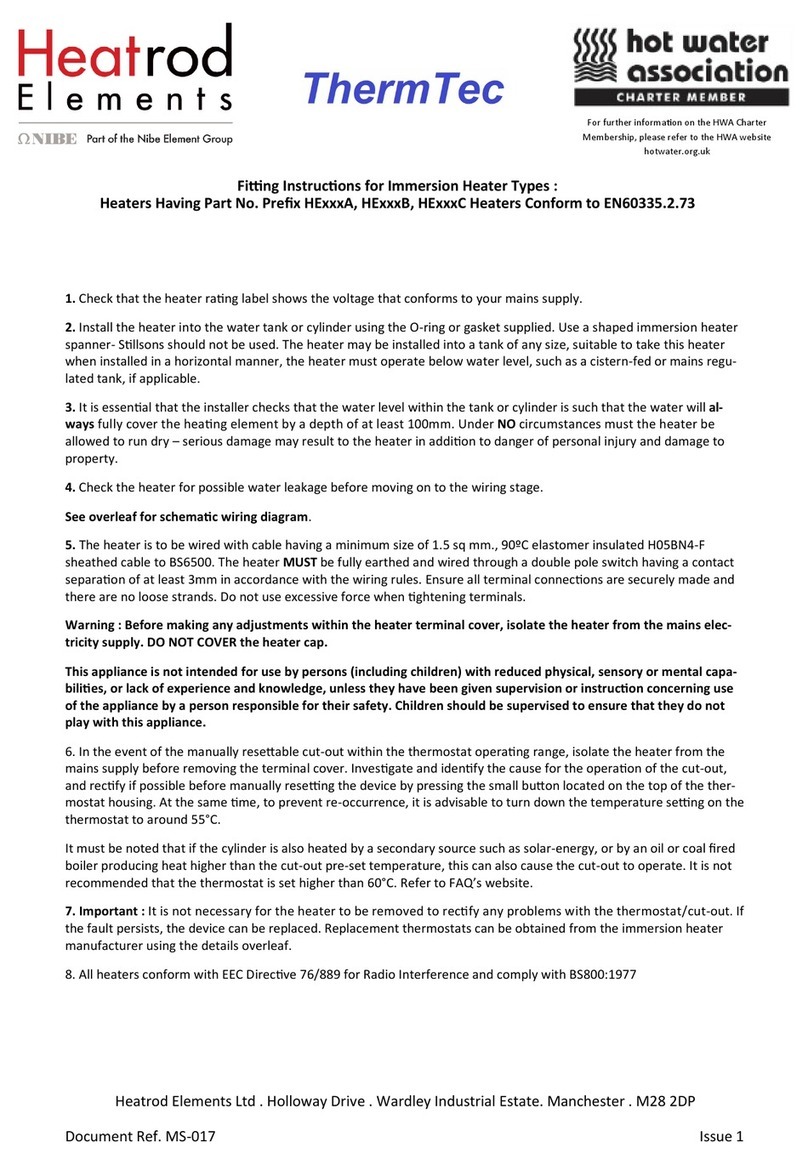

Nibe Heatrod Elements ThermTec HE A Series User manual

Nibe

Nibe SAM 41 User manual

Nibe

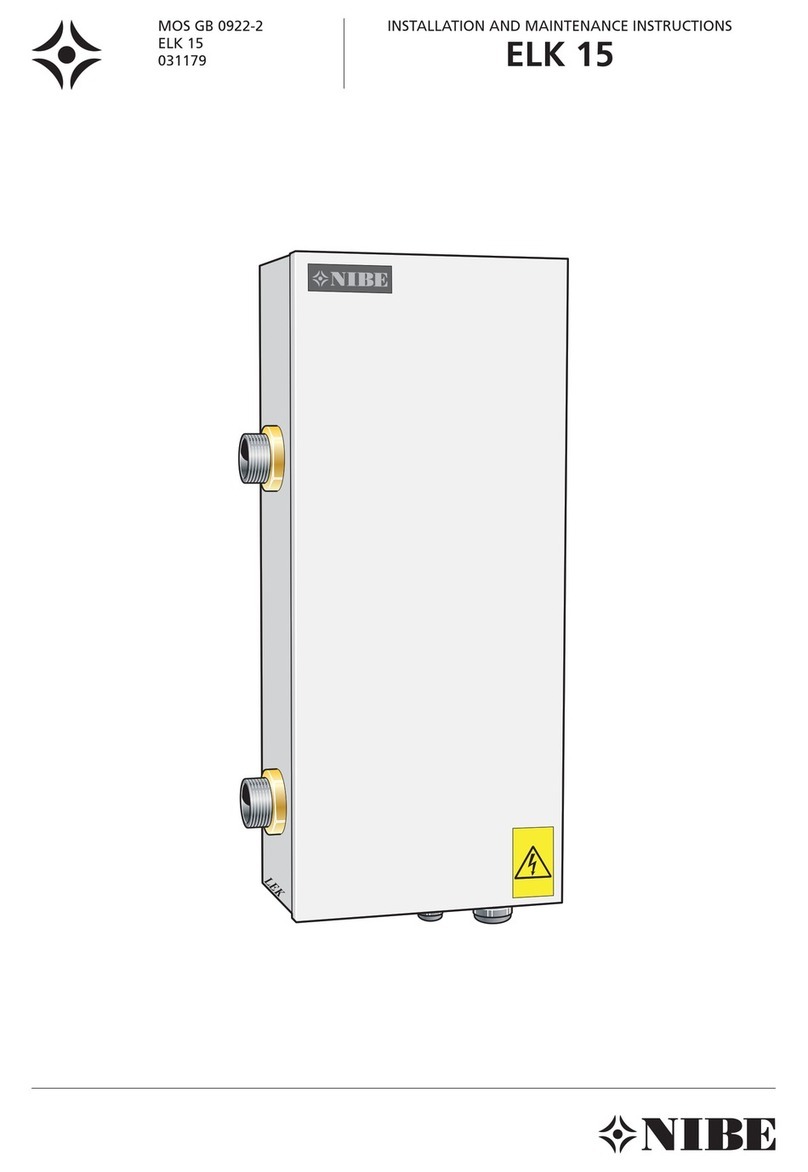

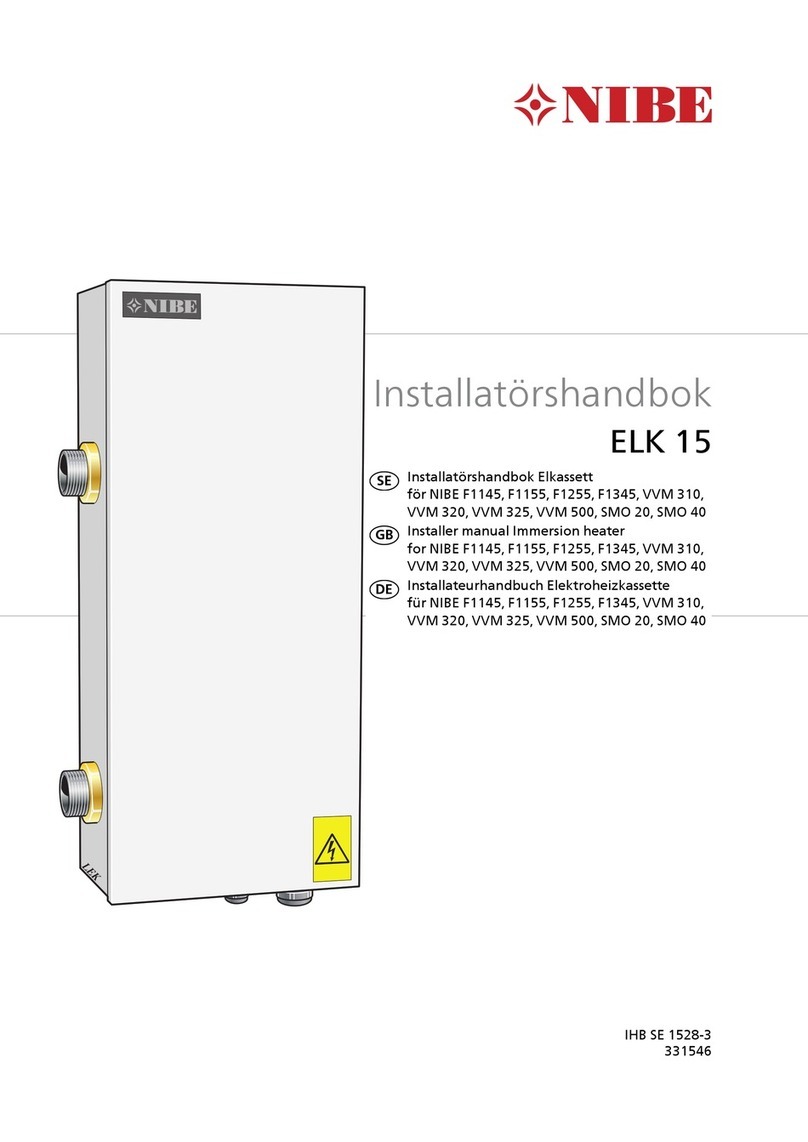

Nibe ELK 15 User manual

Nibe

Nibe EAH 21-1800 User guide

Nibe

Nibe ELK 15 User manual

Nibe

Nibe FIGHTER 310P Operating instructions

Nibe

Nibe ELK 15 User guide

Nibe

Nibe ELK 42 User guide

Popular Heater manuals by other brands

oventrop

oventrop Regucor Series quick start guide

Blaze King

Blaze King CLARITY CL2118.IPI.1 Operation & installation manual

ELMEKO

ELMEKO ML 150 Installation and operating manual

BN Thermic

BN Thermic 830T instructions

KING

KING K Series Installation, operation & maintenance instructions

Empire Comfort Systems

Empire Comfort Systems RH-50-5 Installation instructions and owner's manual

Well Straler

Well Straler RC-16B user guide

EUROM

EUROM 333299 instruction manual

Heylo

Heylo K 170 operating instructions

Eterna

Eterna TR70W installation instructions

Clarke

Clarke GRH15 Operation & maintenance instructions

Empire Heating Systems

Empire Heating Systems WCC65 Installation and owner's instructions