General

The installation must only be carried out by competent

personnel.

The enclosed materials are those required for the install-

ations described (see page 17). In special cases, they may

need to be supplemented. If unsure, contact the supplier.

Information regarding applicable standards and regula-

tions must be obtained prior to the installation and

commissioning of the solar panel system. The electrical

installation, and notification to the power supplier, must

be carried out by qualified electricians. The form for the

inverter must be enclosed with the notification (pre-

completed form is available on www.nibe.se) Please note

that the installation must not be put into use until the

power supplier has given its approval.

NOTE

Installation of a solar panel is an extensive inter-

vention on an existing roof. The roof covering,

particularly on converted and inhabited loft

spaces or where the roof's minimum angle is

undersized (relative to the covering), may re-

quire further measures against moisture because

of wind pressure and drifting snow, this must

be evaluated by the installer on a case to case

basis. The roof design must be able to handle

the wind and snow loading that can occur in

the region.

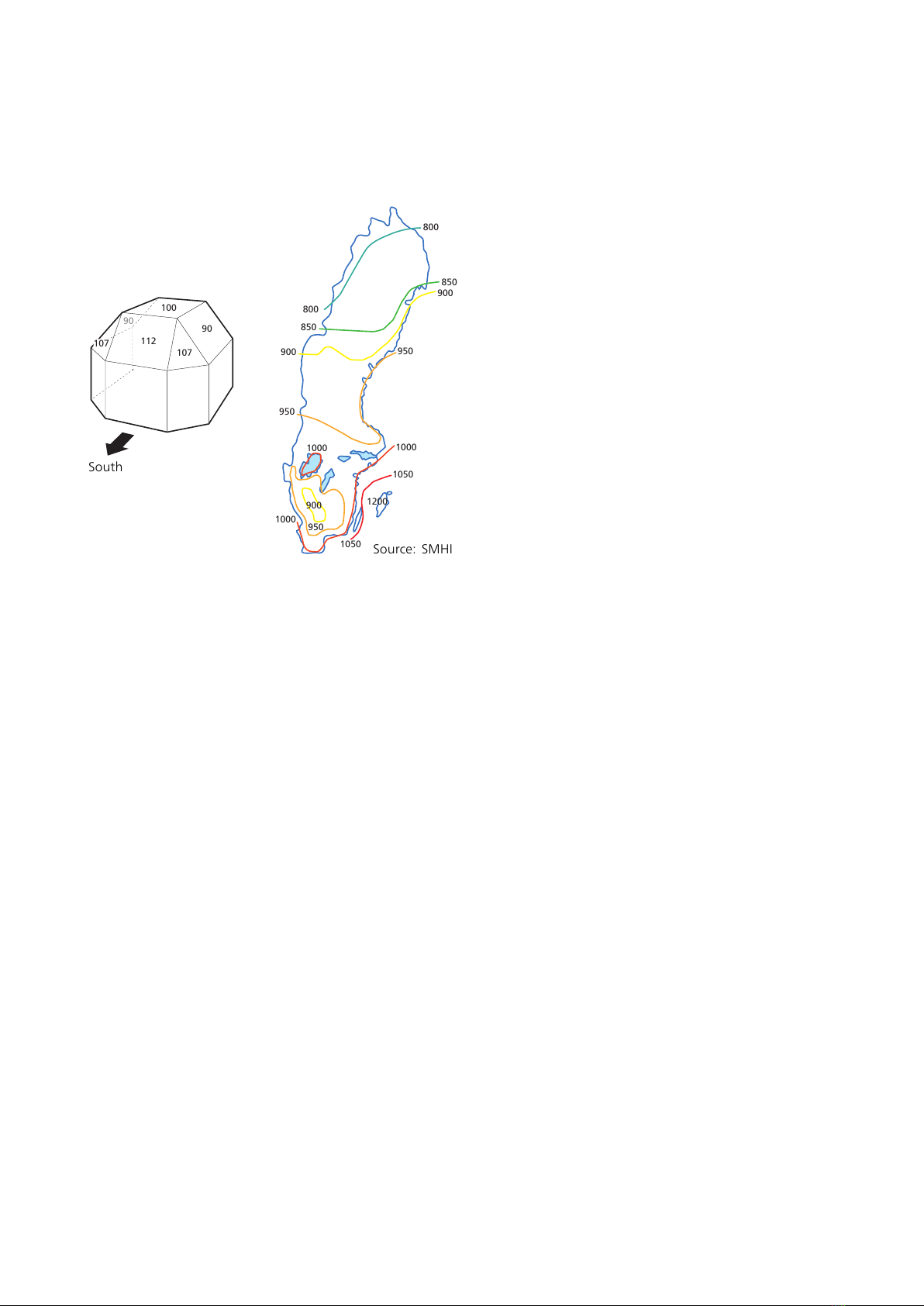

Static load

The installation may only be carried out on roof surfaces

or support constructions with sufficient carrying capacity

and strength. The static load capacity of the roof and

roof construction must if necessary be examined before

the solar panels are installed. Great importance should

be placed on the condition of wood roof structures and

the potential of screwing the mounting devices for the

solar panels to the structure. The roof construction must

be reinforced if necessary. Inspection of the whole solar

panel installation in accordance with DIN 1055 part 4

and 5, or in accordance with country specific regulations

is required, in particular, in areas with snow fall and

strong winds. The characteristics of the installation's

location (prevailing wind direction, whirl winds etc.) must

also be included in the calculation/evaluation of

whether these could mean increased loads. The solar

panels must be installed so that snow drifts from snow

guards or caused by special conditions in the installation

location cannot occur in the vicinity of the solar panels.

The distance from the outer edge of the roof must be at

least 1 m at the sides of roofs and 0.2 m at ridges and

eaves, this is to reduce the risk of the wind ripping the

solar panels off.

The installation system according to DIN 1055 part 5 for

snow zone II is intended for use up to 400 m above sea

level. If the installation is made on a tiled roof, it is recom-

mended that the snow is cleared if it reaches a depth of

more than 30 cm on the solar panels (NOTE! If the snow

has melted, been packed down and then more snow

has fallen and so the density has increased, the snow

may need to be cleared - even though it is not 30 cm

deep.)

If there is a risk that the snow will slide down onto the

panels and in particular behind the rear of raised panels,

snow guards must be installed to prevent this.

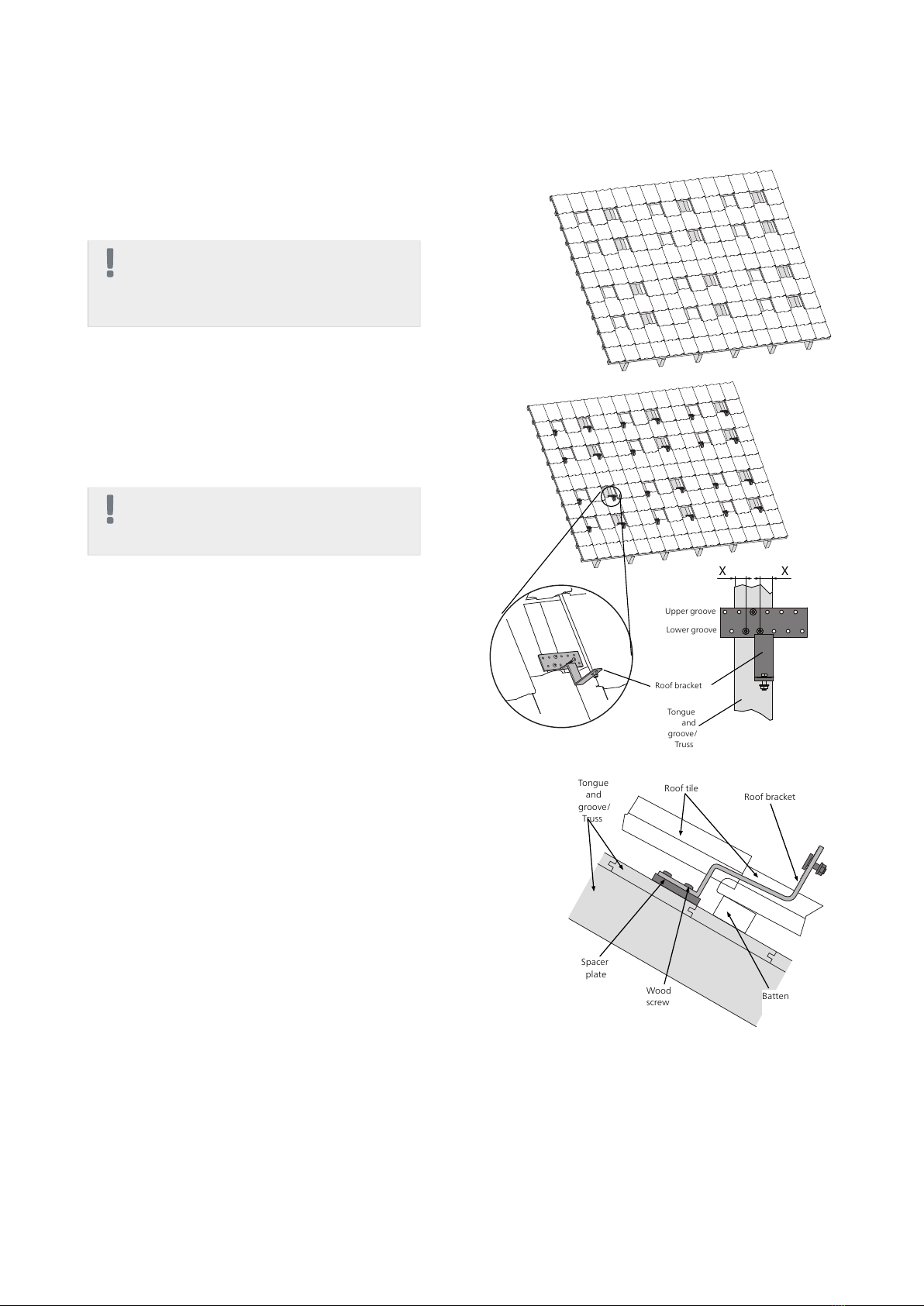

Ensure that the material under roofs with roof tiles is

sufficiently stable to support the roof mounting points.

Otherwise the roof must be reinforced. The installer must

evaluate this and make a decision, if uncertain a structur-

al engineer should be consulted. We recommend that

the roof tiles are cut down so that there are no point

loads between the roof and the roof brackets. The min-

imum distance between roof tiles at overlap points and

the underside of the brackets is 3 mm, this is in order to

allow for any movements in the mounting system in re-

action to the loads that occur.

Lightning protection

If external lightning protection is installed, the solar

panels and the roof structure must be integrated so that

the solar panel field is protected from a direct lightning

strike. The combined solar panel area must be located

within the protective area provided by the lightning

protection. A safety distance of 0.5 m in all directions

from the solar panels to the periphery of the protected

area must be observed.

Safety instructions

■Applicable safety regulations for working on roofs and

similar constructions must be followed.

■Barriers to protect against falling parts must be in-

stalled. This is particularly important for high buildings

and locations where a lot of people pass below the

roof/under the building.

■Personal safety equipment or scaffolding must be used

when working on roofs, according to the applic-

able.regulations.

■Adequate measures must be taken during the install-

ation so that the solar panel does not come loose and

fall.

■Observe the safety distance to the current conducting

cables.

7Chapter 3 | InstallationPV Solar package

3 Installation