Nic Mercury RA-4500 User manual

NIC-704-2005-01

SERVICE MANUAL

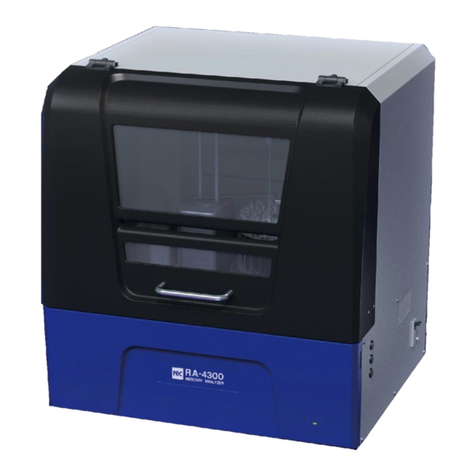

Reducing Vaporization Mercury Analyzer

Mercury RA-4500

Service Manual

Nippon Instruments Corporation

Table of contents

Reducing Vaporization Mercury Analyzer Mercury RA-4500

i

NIC-704-2005-01

Reducing Vaporization Mercury Analyzer Mercury RA-4500

Service Manual

Table of contents

1. INTRODUCTION..............................................................................................................2

1.1. Safety precautions .....................................................................................................2

1.1.1. Meanings and descriptions of symbols................................................................2

1.1.2. Cautions concerning work ...................................................................................2

1.2. Application..................................................................................................................2

2. FIRMWARE UPDATE.......................................................................................................3

2.1. Procedure for updating firmware................................................................................3

2.1.1. File reading..........................................................................................................4

2.1.2. Writing .................................................................................................................5

2.1.3. Validation.............................................................................................................6

2.2. Measures against unsuccessful firmware update.......................................................7

3. REPLACEMENT OF COMPONENTS..............................................................................8

3.1. Replacement of mainboard........................................................................................8

3.2. Replacement of reagent pump...................................................................................9

3.3. Replacement of lamp...............................................................................................11

3.4. Replacement of heater.............................................................................................12

3.4.1. Procedure for removing turntable ......................................................................12

3.4.2. Procedure for removing right side panel............................................................13

3.5. Replacement of arm.................................................................................................17

4. MAINTENANCE .............................................................................................................24

4.1. Daily inspection........................................................................................................24

5. MEASURES AGAINST ABNORMALITY .......................................................................25

5.1. Abnormal blank value...............................................................................................25

5.2. Cleaning procedure..................................................................................................26

5.2.1. Cleaning of reagent tube ...................................................................................26

5.2.2. Cleaning of cap, bubbler, light absorption cell and dehumidifier tube................26

5.3. Poor sensitivity.........................................................................................................26

5.3.1. Recovery from poor sensitivity...........................................................................27

5.4. Checking of and recovery from leak.........................................................................28

6. CONTACT ......................................................................................................................29

1. Introduction

Reducing Vaporization Mercury Analyzer Mercury RA-4500

2

NIC-704-2005-01

1. Introduction

1.1. Safety precautions

1.1.1. Meanings and descriptions of symbols

In the case of mishandling, a user may be killed or suffer a serious injury.

In the case of mishandling, a user may suffer a slight or medium injury or

material damage alone is expected.

1.1.2. Cautions concerning work

- Cut off the power supply before removing any cover of the instrument, otherwise

an electric shock or damage to the instrument may result.

- Before updating the firmware, make sure that it is compatible with the version of

the personal computer software.

- Remove from the instrument chemicals such as sample containers and reagent

bottles on the turntable before starting work because they may be spilled by

mistake at the time of work.

1.2. Application

This manual describes work that can be carried out only by qualified persons who have

received service education at Nippon Instruments Corporation. When carrying out work,

observe safety precautions.

Warning

Caution

Warning

Caution

2. Firmware update

Reducing Vaporization Mercury Analyzer Mercury RA-4500

3

NIC-704-2005-01

2. Firmware update

- Before updating the firmware, make sure that it is compatible with the version of

the personal computer software.

2.1. Procedure for updating firmware

Since RA4Win and the firmware have a rewriting function for the firmware, it can be updated

easily.

Click “System” and “Firmware Update” of RA-4win.

The screen shown above appears. This screen will be used to update the firmware.

Follow the procedure described below:

(1) Make a firmware file read into the personal computer.

(2) Write the read data to the flash memory on the mainboard of the RA4.

(3) Turn off and on the main unit to enable the update.

Warning

2. Firmware update

Reducing Vaporization Mercury Analyzer Mercury RA-4500

4

NIC-704-2005-01

2.1.1. File reading

Click the “Open” button to read the firmware file.

Ordinarily, the file name is “RA4.mot”.

When the reading is completed normally, “File load success.” is displayed and the

“Program” button becomes valid, as shown below. When the read file is not normal, “File

loading fail” is displayed and the “Program” button does not become valid.

2. Firmware update

Reducing Vaporization Mercury Analyzer Mercury RA-4500

5

NIC-704-2005-01

2.1.2. Writing

Click the “Program” button to write the read data to the flash memory of the RA4 main

unit.

Erasing, writing and verification are carried out in that order in the writing procedure.

* Do not turn off the power during the writing procedure. If the power is turned off,

rewriting will be impossible.

The verification can be skipped by erasing the check mark even during execution.

- Writing screen -

- Verification screen -

2. Firmware update

Reducing Vaporization Mercury Analyzer Mercury RA-4500

6

NIC-704-2005-01

2.1.3. Validation

When the writing is completed, the window shown below appears. Click “OK” to terminate

the process.

Turn off the RA4 main unit and turn it on again.

When the power is turned on again, the new program becomes valid.

2. Firmware update

Reducing Vaporization Mercury Analyzer Mercury RA-4500

7

NIC-704-2005-01

2.2. Measures against unsuccessful firmware update

If the power is turned off during the firmware update, the system will not start up when it

is turned on again because the program has not been written normally.

If the system does not start up, it is impossible to rewrite the program.

In such a case, start a boot mode, which is exclusively for firmware rewriting, and rewrite

the firmware.

(1) Turn off the power, open the rear cover of the main unit, and set the SW1 on the

CPU board to the boot mode.

(2) Make sure that the personal computer and the RA4 main unit have been connected

with the Ethernet cable, and then turn on the power.

(3) Start RA4Win.

(4) Carry out writing in the same procedure as “2.1.Procedure for updating firmware”.

(5) When the writing is completed, turn off the power, return the SW1 on the CPU board

to the normal mode as before, and turn on the power again. Now the procedure is

completed.

Normal mode Boot mode

Normal mode

Boot mode

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

8

NIC-704-2005-01

3. Replacement of components

- Cut off the power supply before removing any cover of the instrument, otherwise

an electric shock or damage to the instrument may result.

- Remove from the instrument chemicals such as sample containers and reagent

bottles on the turntable before starting work because they may be spilled by

mistake at the time of work.

3.1. Replacement of mainboard

(1) Remove the six screws from the rear of the instrument.

(2) Disconnect the connectors connected to the mainboard and remove the six screws.

(3) Attach a new mainboard in the procedure reverse to that for the removal.

Warning

Caution

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

9

NIC-704-2005-01

3.2. Replacement of reagent pump

(1) To remove the pump mount, remove the screw of the side panel.

(2) Remove the screw of the pump mount.

(3) Push the pump mount inside.

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

10

NIC-704-2005-01

(4) Remove the screws of the pump from the inside of the pump mount, and replace the

pump.

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

11

NIC-704-2005-01

3.3. Replacement of lamp

External appearance of optical system

Remove the screws of the optical system

box shown above, and remove the

intermediate plate.

Then disconnect the connectors of the

constant temperature cap and lamp.

Loosen the screws fixing the constant

temperature cap, and remove it.

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

12

NIC-704-2005-01

Remove the screws of the plate fixing the

lamp to the constant temperature cap.

The front of the lamp is shown on the left.

Fix the lamp such that the front of the lamp

is aligned with the direction of the hole in

the constant temperature cap.

Attach the lamp in the procedure reverse to

that for the removal.

After attaching the optical system as

before, carry out “OpticalAdjust” to adjust

the voltage of the optical system in the

maintenance mode on the screen shown

on the left.

* Adjust the optical system 20 minutes or

more after turning on the instrument.

* After the replacement, be sure to reset the count in the maintenance mode.

3.4. Replacement of heater

(Before the replacement, disconnect the power cable.)

3.4.1. Procedure for removing turntable

(1) Turn manually the knob in the center of the turntable, and remove it.

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

13

NIC-704-2005-01

(2) Pull the turntable right upward to remove it.

3.4.2. Procedure for removing right side panel

(1) Remove the screw shown below from the inside of the instrument.

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

14

NIC-704-2005-01

(2) Remove the six screws on the right side.

(3) Since the right side panel has been hung on screws, it can be removed by applying

force to it.

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

15

NIC-704-2005-01

(4) Remove the four screws fixing the heater.

(5) Pull out the pins connected to the terminal block on the right side, connect the pins of a

new heater and assemble the terminal block.

3. Replacement of components

Reducing Vaporization Mercury Analyzer Mercury RA-4500

16

NIC-704-2005-01

(6) Attach the heater such that the slant metal plate comes to the inside.

Service manual

Reducing Vaporization Mercury Analyzer Mercury RA-4500

17

3.5. Replacement of arm

(1) View before replacement. (Ordinarily, the

covers have been attached.)

(2) Remove the hexagon socket head cap

screws of the cap mounting plate.

(3) Disconnect the pump tube and effluent tube from the inlet and outlet.

(4) Remove the screws fixing the pump unit case.

Service manual

Reducing Vaporization Mercury Analyzer Mercury RA-4500

18

(5) Remove the pump unit from the cabinet.

(6) When the removal is difficult, disconnect

the air pump and reagent pump

connectors.

(7) Disconnect the “COLOR” connector.

(8) Remove the screws fixing the dispensing

case.

(9) Remove the connectors for the

dispensing unit.

(10) Remove the dispensing case.

Service manual

Reducing Vaporization Mercury Analyzer Mercury RA-4500

19

(11) A new unit is shown below. Replace

the unit.

(12) The flange in the trapezoidal thread of

the new unit has been changed from

resin to brass, and the vertical torque

has been tripled.

(13) Prevent the shafts from loosening with

screw locking. (14) Fix the components using a ball point

driver so that they do not loosen.

(15) Attach both shafts and make sure of a

right angle.

(16) If it is impossible to obtain a right

angle, make a fine adjustment by

inserting foil.

Table of contents

Other Nic Measuring Instrument manuals