NOVUS AUTOMATION 2/52

1SAFETY ALERTS...............................................................................................................................................................................................3

2INTRODUCTION ................................................................................................................................................................................................4

3IDENTIFICATION ...............................................................................................................................................................................................5

3.1 MODELS WITHOUT DISPLAY ...................................................................................................................................................................5

3.2 MODELS WITH DISPLAY ...........................................................................................................................................................................5

3.3 DEVICE MODELS .......................................................................................................................................................................................6

4DISPLAY INDICATIONS ....................................................................................................................................................................................7

4.1 HOME SCREEN..........................................................................................................................................................................................7

4.2 DISPLAYING MAXIMUM AND MINIMUM VALUES ...................................................................................................................................7

4.3 DISPLAYING OTHER PSYCHROMETRIC PROPERTIES ........................................................................................................................7

4.4 SIGNALS .....................................................................................................................................................................................................8

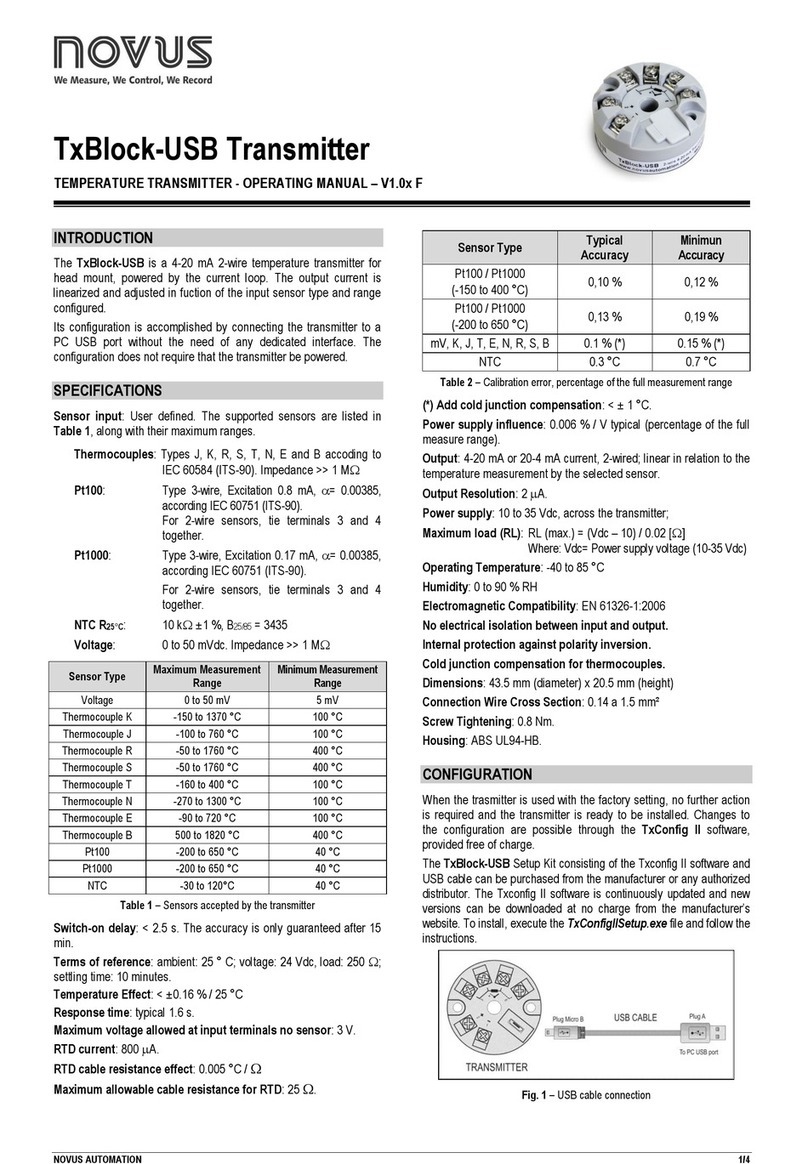

5INSTALLATION ..................................................................................................................................................................................................9

5.1 MECHANICAL INSTALLATION ..................................................................................................................................................................9

5.1.1 DIMENSIONS ....................................................................................................................................................................................9

5.1.1.1 RHT Climate TRANSMITTER (WM MODEL) ............................................................................................................................. 9

5.1.1.2 RHT Climate TRANSMITTER (DM MODEL) ............................................................................................................................ 10

5.1.2 REMOVING AND INSTALLING THE FRONT COVER...................................................................................................................10

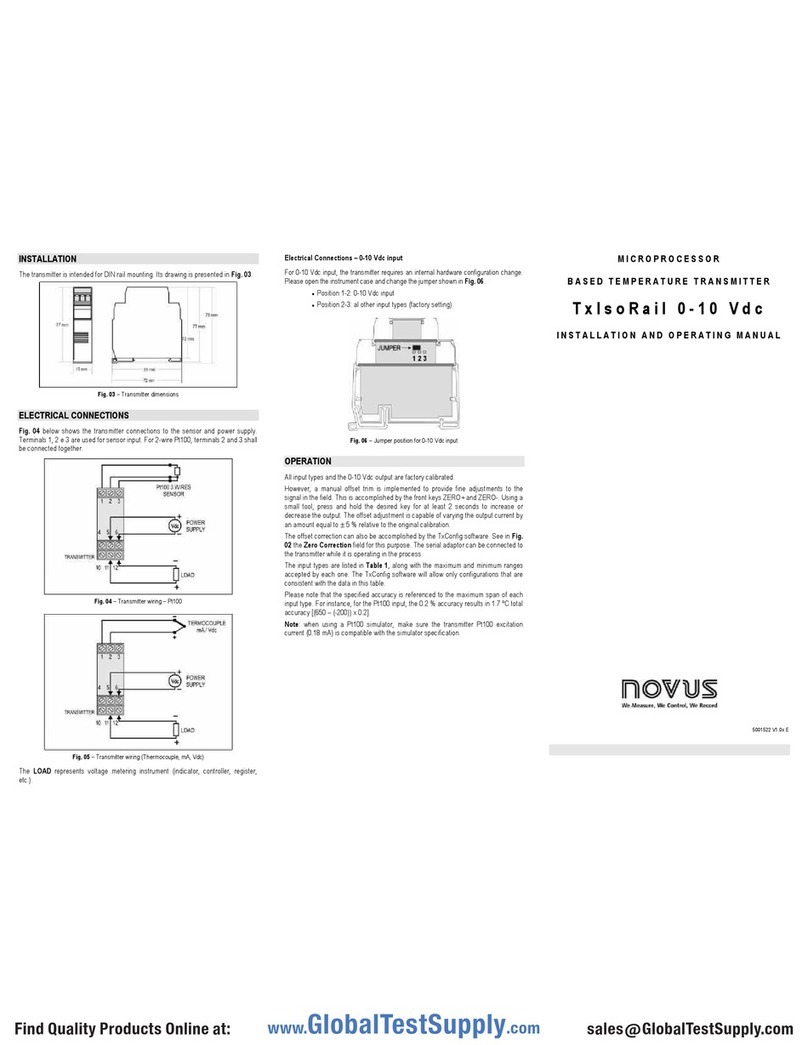

5.2 ELECTRICAL INSTALLATION..................................................................................................................................................................11

5.2.1 INSTALLATION RECOMMENDATIONS.........................................................................................................................................11

5.2.2 SPECIAL PRECAUTION.................................................................................................................................................................11

5.2.3 ELECTRICAL CONNECTIONS.......................................................................................................................................................11

5.2.4 USB CONNECTION ........................................................................................................................................................................11

5.3 SENSOR MAINTENANCE ........................................................................................................................................................................12

5.3.1 PRECAUTIONS WITH SENSORS..................................................................................................................................................12

5.3.2 SENSOR REPLACEMENT .............................................................................................................................................................12

6PARAMETER CYCLES....................................................................................................................................................................................14

7CONFIGURATION............................................................................................................................................................................................15

7.1 ANALOG OUTPUTS 0VT1 / 0VT2 ..........................................................................................................................................................15

7.2 ALARM OUTPUTS ALM1 / ALM2 .............................................................................................................................................................17

7.3 BUZZER CONFIGURATION CYCLE ........................................................................................................................................................20

7.4 HMI CONFIGURATION CYCLE................................................................................................................................................................22

7.5 DIAGNOSTIC CYCLE ...............................................................................................................................................................................24

7.6 COMMUNICATION CYCLE ......................................................................................................................................................................25

7.7 GENERAL CONFIGURATION CYCLE .....................................................................................................................................................26

7.8 INFORMATION CYCLE ............................................................................................................................................................................28

8PARAMETERS MAP ........................................................................................................................................................................................29

9USB INTERFACE .............................................................................................................................................................................................30

9.1 CONNECTING TO A COMPUTER ...........................................................................................................................................................30

9.2 CONNECTING TO A SMARTPHONE.......................................................................................................................................................30

10 SERIAL COMMUNICATION.............................................................................................................................................................................31

10.1 HOLDING REGISTER TABLE ..................................................................................................................................................................31

11 SIGNOW SOFTWARE AND APP ....................................................................................................................................................................38

11.1 SIGNOW SOFTWARE ..............................................................................................................................................................................38

11.2 SIGNOW APP............................................................................................................................................................................................38

11.3 STARTING SIGNOW.................................................................................................................................................................................38

11.4 CONNECTING TO THE SIGNOW SOFTWARE.......................................................................................................................................39

11.5 CONNECTING TO THE SIGNOW APP....................................................................................................................................................40

11.6 CONFIGURING THE DEVICE ..................................................................................................................................................................41

11.6.1 GENERAL / BASIC..........................................................................................................................................................................41

11.6.2 COMMUNICATION..........................................................................................................................................................................41

11.6.3 TEMPERATURE..............................................................................................................................................................................42

11.6.4 RELATIVE HUMIDITY.....................................................................................................................................................................42

11.6.5 OUTPUTS 1 AND 2 .........................................................................................................................................................................43

11.6.6 ALARMS 1 AND 2 ...........................................................................................................................................................................43

11.6.7 HMI ..................................................................................................................................................................................................44

11.6.8 DIAGRAM ........................................................................................................................................................................................45

11.6.9 FIRMWARE UPDATE......................................................................................................................................................................46

11.7 PERFORMING THE DIAGNOSTICS ........................................................................................................................................................47

12 TECHNICAL SPECIFICATIONS ......................................................................................................................................................................49

13 WARRANTY .....................................................................................................................................................................................................51

14 APPENDIX I – NOTIONS ABOUT PSYCHROMETRY ....................................................................................................................................52