45372301TH Rev.2 vi /

Oki Data CONFIDENTIAL

CONTENTS

MJ-1038

1. SPECIFICATIONS, ACCESSORY AND CONSUMABLES.......................................... 1-1

1.1 Specifications....................................................................................................................... 1-1

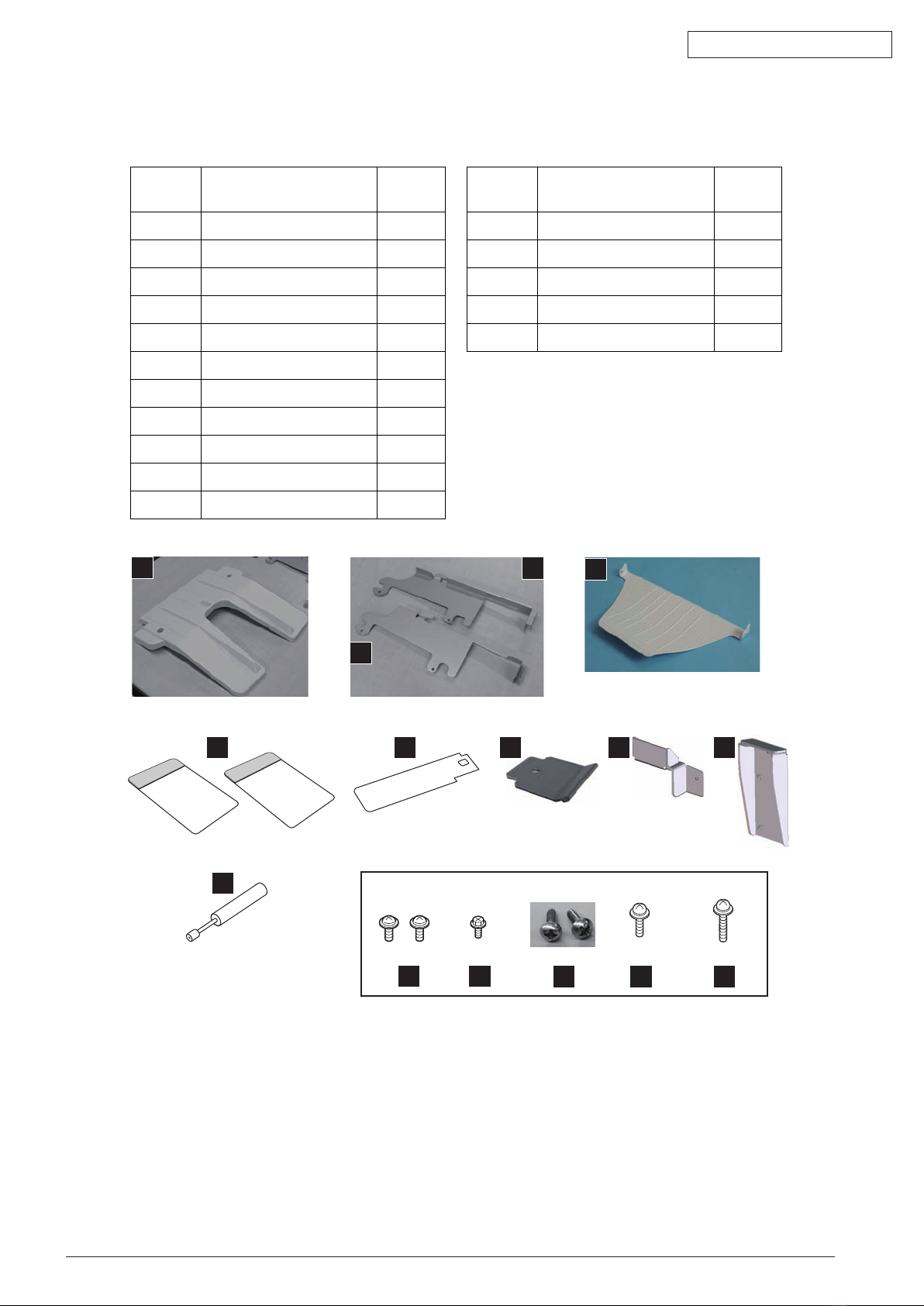

1.2 Accessory ............................................................................................................................ 1-3

1.3 Consumables....................................................................................................................... 1-4

2. GENERAL DESCRIPTION............................................................................................ 2-1

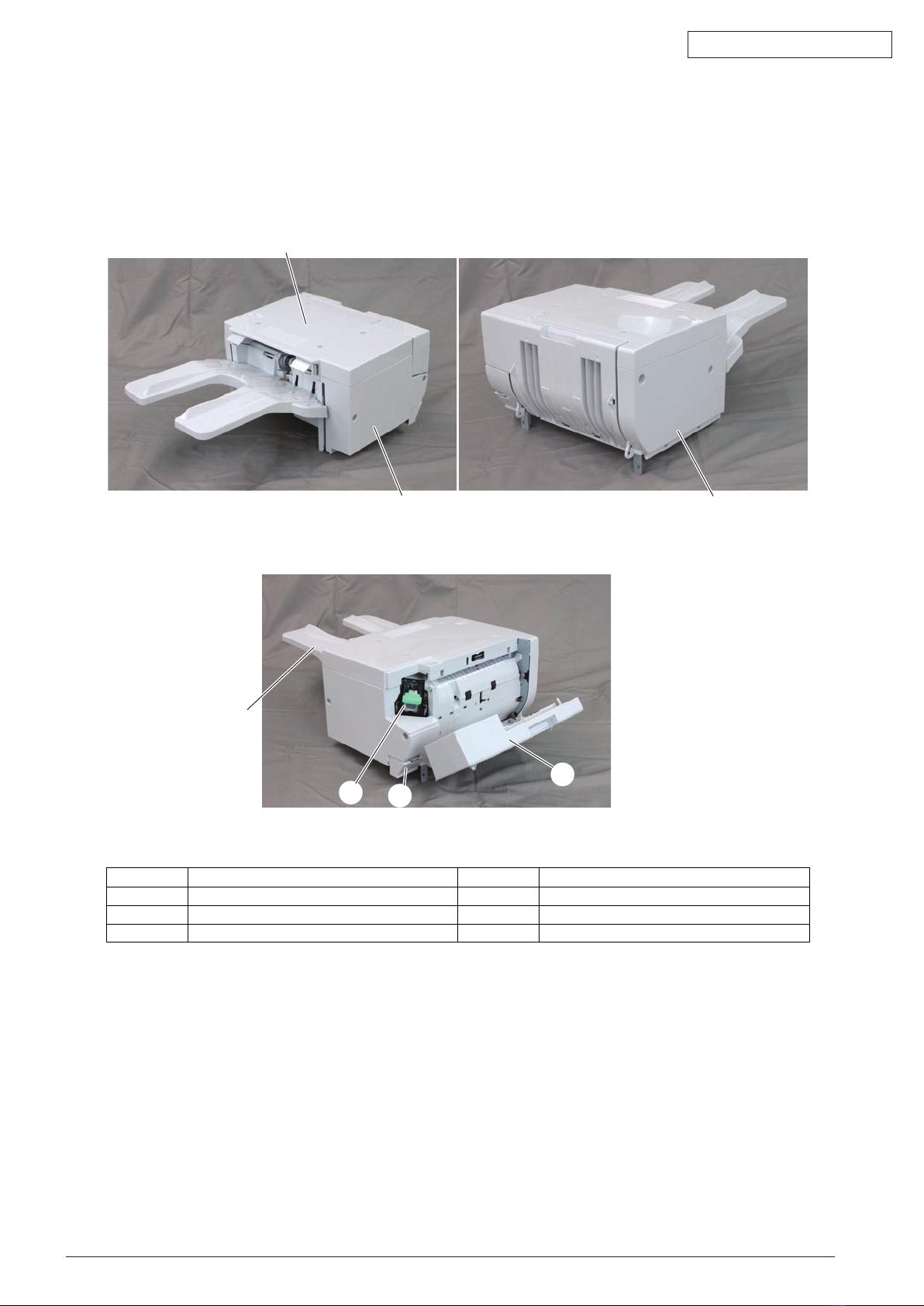

2.1 Main Components................................................................................................................ 2-1

2.2 Sectional View ..................................................................................................................... 2-2

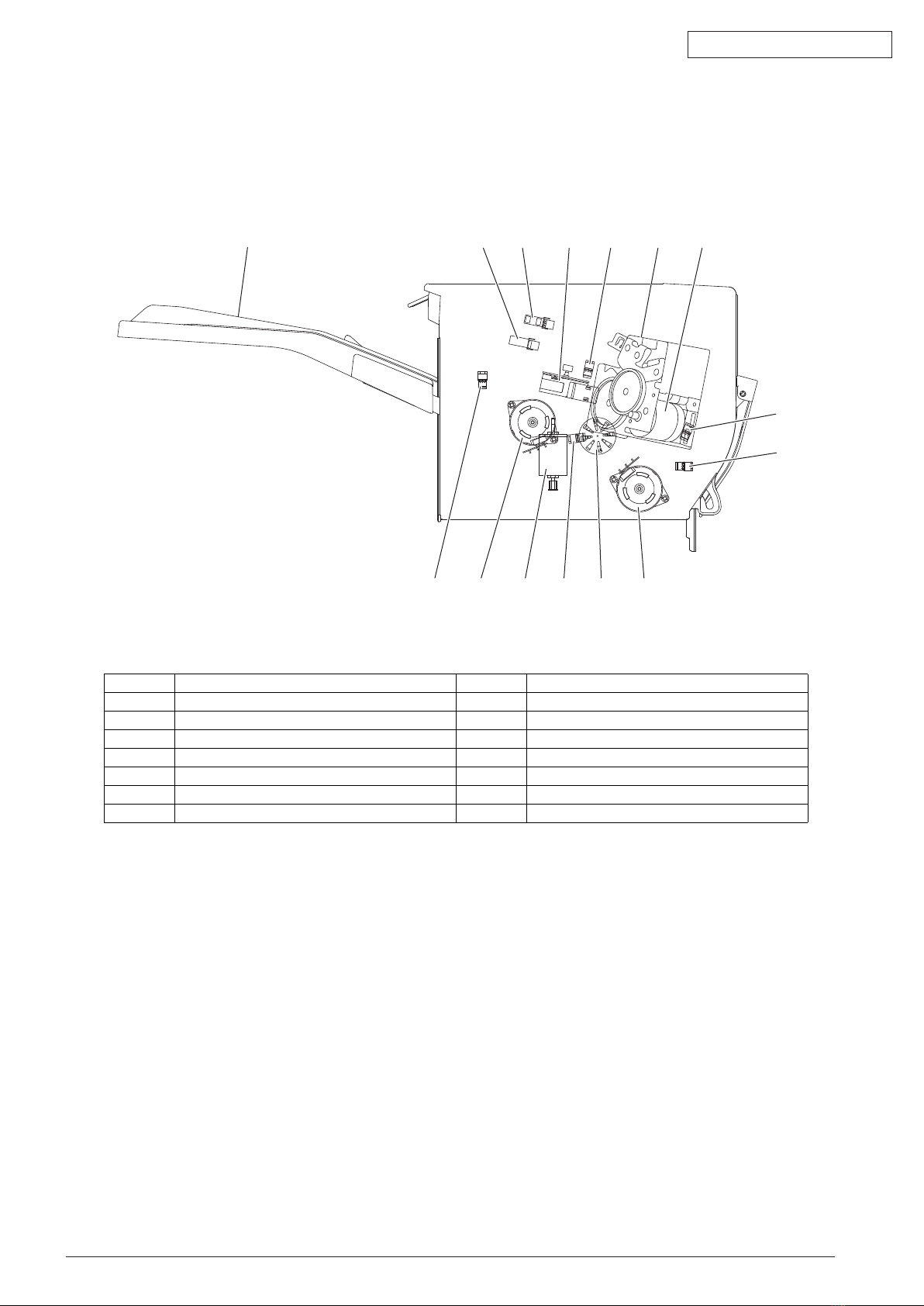

2.3 Electric Parts Layout............................................................................................................ 2-4

2.4 Symbols and Functions of Various Components................................................................. 2-6

2.5 Diagram of Signal Blocks..................................................................................................... 2-8

3. DESCRIPTION OF OPERATIONS ............................................................................... 3-1

3.1 Basic Operations ................................................................................................................. 3-1

3.1.1 Specifications ......................................................................................................... 3-1

3.1.2 Transport drive system - General description ........................................................ 3-2

3.1.3 Jam detection ......................................................................................................... 3-9

4. DISASSEMBLY AND INSTALLATION......................................................................... 4-1

4.1 Disassembly and Replacement of Covers........................................................................... 4-1

4.1.1 Upper cover............................................................................................................ 4-1

4.1.2 Right cover ............................................................................................................. 4-1

4.1.3 Left cover................................................................................................................ 4-2

4.2 Disassembly and Replacement of Sensors and Switches................................................... 4-3

4.2.1 Guide upper ASSY ................................................................................................. 4-3

4.2.2 Guide rear ASSY.................................................................................................... 4-3

4.2.3 Entrance transport sensor (S1) .............................................................................. 4-6

4.2.4 Exit transport sensor (S2)....................................................................................... 4-6

4.2.5 Alignment plate home position sensor (R) (S4)...................................................... 4-7

4.2.6 Alignment plate home position sensor (L) (S5) ...................................................... 4-7

4.2.7 Ejector home position sensor (S7) ......................................................................... 4-8

4.2.8 Ejector encoder sensor (S8)................................................................................. 4-10

4.2.9 Stapler paper sensor (S14) .................................................................................. 4-13

4.2.10 Stack home position sensor (S9) ......................................................................... 4-15

4.2.11 Paper support home position sensor (S6) ............................................................ 4-17

4.2.12 Door switch (SW2) ............................................................................................... 4-20

4.2.13 Stacker tray lower limit switch (SW1) ................................................................... 4-20

4.2.14 Lever path home position sensor (S15) ............................................................... 4-21

4.3 Disassembly and Replacement of motors ......................................................................... 4-22

4.3.1 Entrance transport motor (M1) ............................................................................. 4-22

4.3.2 Exit transport motor (M2)...................................................................................... 4-22

4.3.3 Alignment motor (R) (M4)..................................................................................... 4-23

4.3.4 Alignment motor (L) (M5) ..................................................................................... 4-25

4.3.5 Paddle motor (M3)................................................................................................ 4-27

4.3.6 Paper support motor (M6) .................................................................................... 4-28

4.3.7 Ejector motor (M7)................................................................................................ 4-31

4.3.8 Stacker motor (M8)............................................................................................... 4-34

4.3.9 Lever path motor (M10)........................................................................................ 4-35

4.4 Disassembly and Replacement of transport system.......................................................... 4-37

4.4.1 Entrance transport roller....................................................................................... 4-37

4.4.2 Exit Transport roller .............................................................................................. 4-38

4.4.3 Exit roller (PM)...................................................................................................... 4-39

4.4.4 Sub paddle ........................................................................................................... 4-41