45372301TH Rev.1 vi /

Oki Data CONFIDENTIAL

CONTENTS

1. SPECIFICATIONS, ACCESSORY AND CONSUMABLES ...............................1-1

1.1 Specifications............................................................................................... 1-1

1.2 Accessory ....................................................................................................1-3

1.3 Consumables ...............................................................................................1-4

2. GENERAL DESCRIPTION ................................................................................2-1

2.1 Main Components........................................................................................ 2-1

2.2 Sectional View .............................................................................................2-2

2.3 Electric Parts Layout ....................................................................................2-4

2.4 Symbols and Functions of Various Components .........................................2-6

2.5 Diagram of Signal Blocks.............................................................................2-8

3. DESCRIPTION OF OPERATIONS.....................................................................3-1

3.1 Basic Operations..........................................................................................3-1

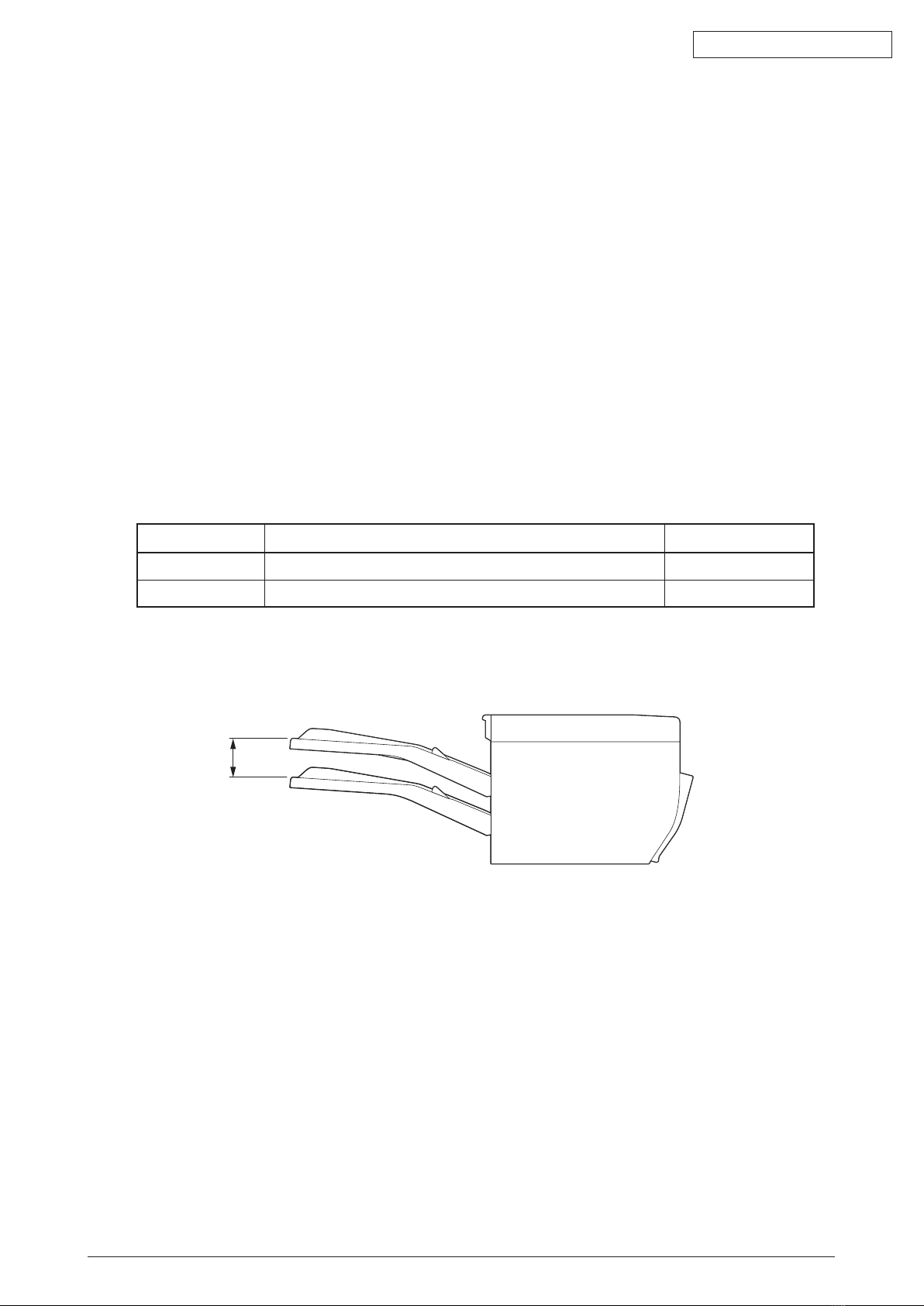

3.1.1 Specifications............................................................................................................3-1

3.1.2 Transport drive system - General description.......................................................... 3-2

3.1.3 Jam detection .......................................................................................................... 3-9

4. DISASSEMBLY AND INSTALLATION ..............................................................4-1

4.1 Disassembly and Replacement of Covers ...................................................4-1

4.1.1 Upper cover ..............................................................................................................4-1

4.1.2 Front cover................................................................................................................4-1

4.1.3 Rear cover ............................................................................................................... 4-2

4.2 Disassembly and Replacement of Sensors and Switches ...........................4-3

4.2.1 Guide upper ASSY................................................................................................... 4-3

4.2.2 Guide rear ASSY ..................................................................................................... 4-3

4.2.3 Entrance transport sensor (S1)................................................................................ 4-6

4.2.4 Exit transport sensor (S2)........................................................................................ 4-6

4.2.5 Front alignment plate home position sensor (S4).....................................................4-7

4.2.6 Rear alignment plate home position sensor (S5) .....................................................4-7

4.2.7 Ejector home position sensor (S7) .......................................................................... 4-8

4.2.8 Ejector encoder sensor (S8)...................................................................................4-10

4.2.9 Stapler paper sensor (S14).....................................................................................4-13

4.2.10 Stack home position sensor (S9) ...........................................................................4-15

4.2.11 Paper support home position sensor (S6)..............................................................4-17

4.2.12 Door switch (SW2)................................................................................................. 4-20

4.2.13 Stacker tray lower limit switch (SW1)..................................................................... 4-20

4.2.14 Lever path home position sensor (S15) ................................................................. 4-21

4.3 Disassembly and Replacement of motors..................................................4-22

4.3.1 Entrance transport motor (M1)............................................................................... 4-22

4.3.2 Exit transport motor (M2)....................................................................................... 4-22

4.3.3 Front alignment motor (M4) ................................................................................... 4-23

4.3.4 Rear alignment motor (M5).................................................................................... 4-25

4.3.5 Paddle motor (M3) ................................................................................................. 4-27

4.3.6 Paper support motor (M6) ..................................................................................... 4-28

4.3.7 Ejector motor (M7) ................................................................................................. 4-31

4.3.8 Stacker motor (M8) ................................................................................................ 4-34

4.3.9 Lever path motor (M10).......................................................................................... 4-35