ix

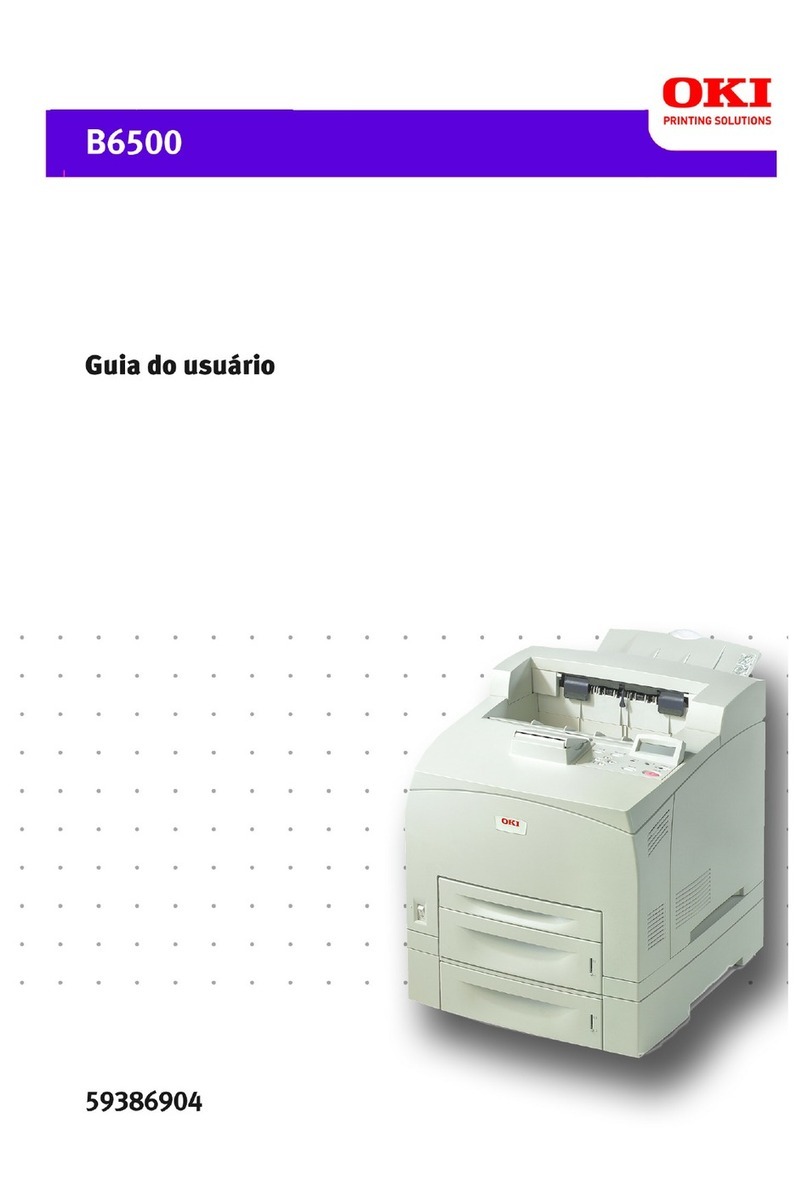

5. Installation

5.1 Power source

Do not plug too many leads into a single socket. Use a dedicated electric outlet and confirm that the

power is within the specification.

Connect the single power cord to an electric outlet which supplies power more

than the maximum power consumption of this laser printer.

5.2 Ground

Be sure to establish the ground of this laser printer.

Be sure to connect the ground of this laser printer with one of the followings:

- Grounding terminal of an electric outlet

- Copper or the like which is embedded 650 mm or deeper in the ground

- Grounding terminal for which the grounding work has been carried out

Be sure not to establish a ground with the followings:

- Gas pipe

- Ground for telephone

- Water pipe which is partially made from plastic

When establishing a ground, be sure not to use the 2pin - 3pin conversion plug.

5.3 Installation location

- Make sure there is enough space for operations of this laser printer.

- Install where the temperature and the humidity meet the following environment:

- During operation:5 to 35 degree C / 15 to 85 %RH (70%RH at 35 degree C, 85%RH at 32 degree C).

- no condensation

- Not in operation:-20 to 40 degree C / 5 to 85%RH (A place with no condensation)

- Install in a flat place with the angle of gradient of 5 degree or less.

- Install in a place with the illumination of 3000 Lux or less. (Avoid direct sunlight.)

- Avoid a place near a water system, a humidifier or fire, a dusty place, or a place which gets air blasting

of an air conditioning.

- Avoid where volatile or flammable gas is generated.

- Avoid an ill-ventilated place.

- Avoid an unstable and non-durable place.