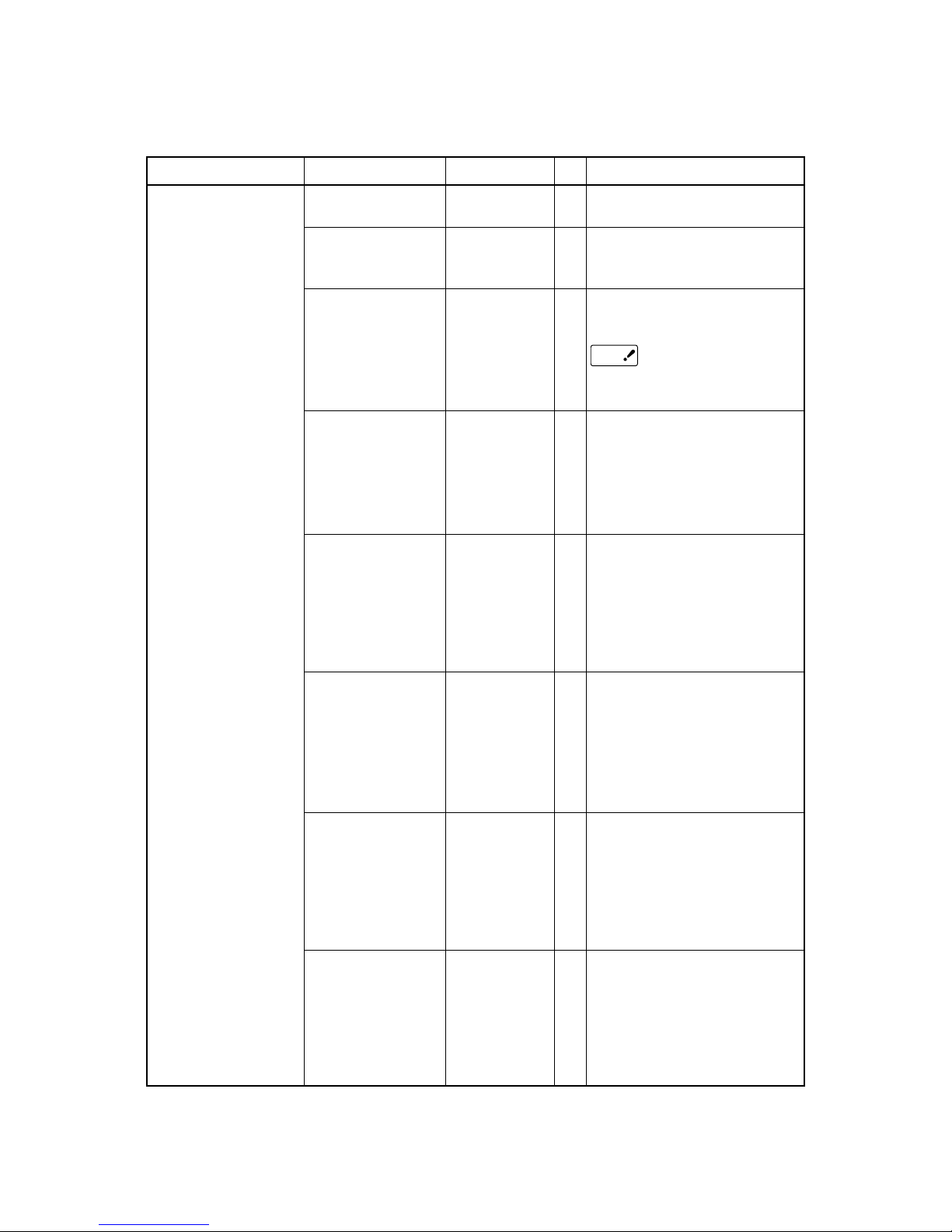

Table 5-0. Maintenance Menu Display Table (2/2)

During the Engine Self-Diagnosis Mode, switch operations and the LCD display is instructed by the

engine firmware, therefore, it will vary from the specifications of the controller firmware operations.

Note that the Engine Self-Diagnosis Mode can also be executed in the state with the controller PCD

removed.

For details, accordingly refer to the Engine Specifications Manual.

Value

Execute

NEXT

Execute

Execute

Enable

Disable

Enable

Disable

Enable

Disable

Execute

Execute

Item

Format HDD

Format

Flash ROM

Reset

EEPROM

Reset

Parameter

IBM PPR

III XL

EPSON

FX

HP-GL/2

Slot 0

Slot 1

Category

Maintenance

Menu

Personality

Format

Flash ROM

Function

Initialize the HDD. When executed it

will escape from the menu and start

initializing the HDD.

[Display Condition]

¥Mount HDD ( Boot Menu - Storage

Setup - Enable Initialization

Enable, Boot Menu - Storage

Setup - Enable HDD Yes)

This displays the menu to initialize

the Flash ROM.

This resets the EEPROM details to

the factory preset (factory default)

value. It automatically reboots after

the settings are made and applied.

* Some special items are not

initialized.

This resets the EEPROM details to

the factory preset (factory default)

value. At that time, the OEM related

settings that are not initialized with

Reset EEPROM will also be

initialized.

It automatically reboots after the

settings are made and applied.

* Some of the PU, network, etc.

cannot be initialized.

Changes the default PDL language

supported according to the destination.

The PDL language disabled from

this menu will no longer be displayed

on the Print Setup — Personality

of the Function menu. When

receiving print data in the disabled

PDL language, display INVALID

DATA and dispose the incoming

data. (HP-GL/2 is currently under

development and there are no plans

scheduled for application for the

product). PDF requires Adobe

Postscript, therefore, it is not

possible to turn PDF ON/OFF by

itself (if Adobe Postscript is

DISABLED, the PDF Function will

also be DISABLED).

It is not possible to DISABLE Adobe

Postscript and PDF with PX711/713.

(It shall be usually used in the

ENABLE state. Though DISABLE is

set the incoming data will still be

processed. It has been incorporated

for future extension purposes.)

Initialize the Flash ROM.

Escape the menu to execute, then

start formatting the Flash device

mounted on the resident (onboard).

Initialize the Flash ROM.

Escape the menu to execute, then start

formatting the Flash device mounted

on the wireless LAN (Optional).

Old Menu

SYSTEM

MAINENANCE

MENU —

MAINTENANCE

MENU — HDD

INITIALIZE

SYSTEM

MAINENANCE

MENU -

MAINTENANCE

MENU — FLASH

INITIALIZE

SYSTEM

MAINENANCE

MENU -

MAINTENANCE

MENU — MENU

RESET

SYSTEM

MAINENANCE

MENU -

PERONALITY —

IBM PPR III XL

SYSTEM

MAINENANCE

MENU -

PERONSALITY

— EPSON fx

SYSTEM

MAINENANCE

MENU -

PERSONALITY

— hp-gl/2

DF

-

-

-

-

*E

*J

*E

*J

*JE

-

-

Valid

ET

RB

RB

RB

ET

ET

Save

-

-

-

-

-

-

-

Troubleshooting Guide Page 4