41356801TH Rev.1 4 /

CONTENTS

1. CONFIGURATION.................................................................................................. 7

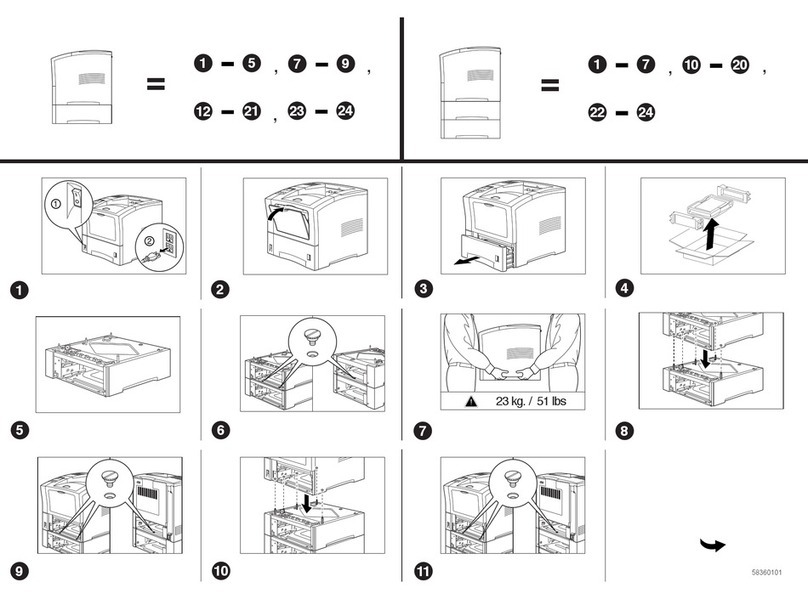

1.1 System Configuration ..................................................................................... 7

1.2 Printer Configuration....................................................................................... 9

1.3 Optional Configuration .................................................................................... 10

1.4 Specification ................................................................................................... 12

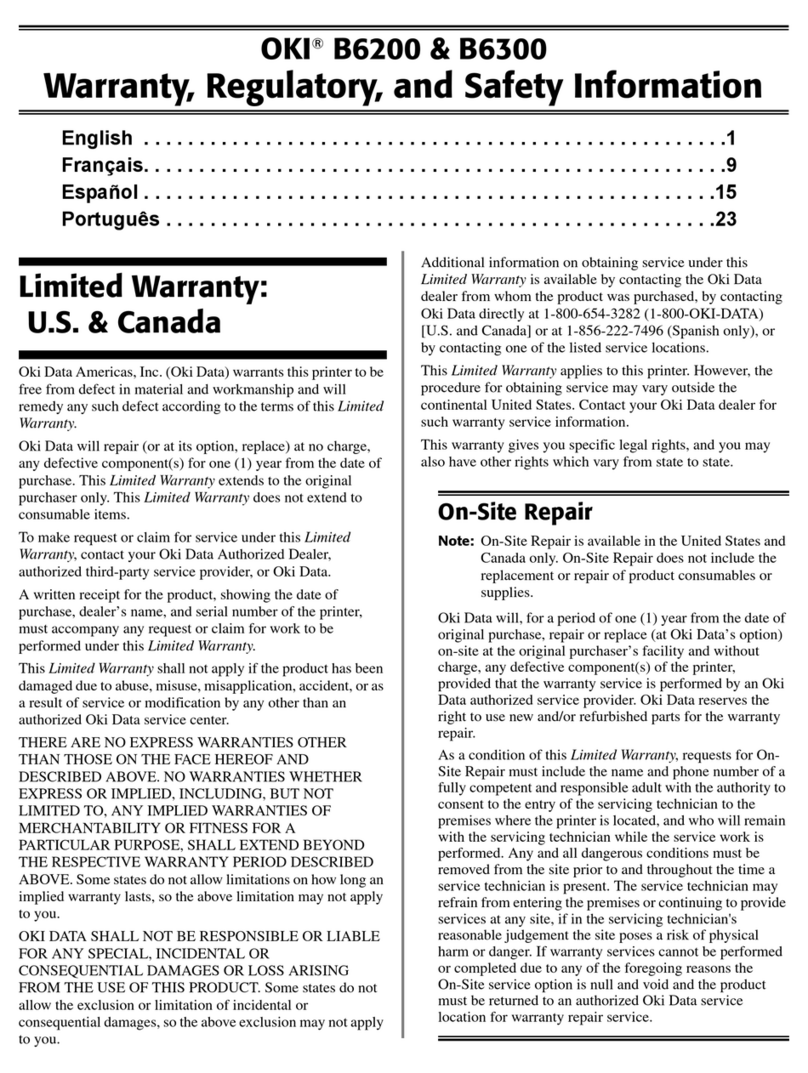

1.5 Safety Standards ............................................................................................ 14

1.5.1 Certification Label..................................................................................................... 14

1.5.2 Warning Label .......................................................................................................... 14

1.5.3 Warning/Caution Marking ......................................................................................... 15

2. OPERATION DESCRIPTION ................................................................................. 16

2.1 Main Control Board......................................................................................... 18

2.2 Power Supply/Sensor Board........................................................................... 19

2.3 Electrophotographic Process.......................................................................... 21

2.3.1 Electrophotographic Process Mechanism ................................................................ 21

2.3.2 Electrophotographic Process.................................................................................... 24

2.3.3 Process Operation Descriptions............................................................................... 27

2.3.4 Revision of LED Head Illumination........................................................................... 37

2.4 Paper Jam Detection ...................................................................................... 38

2.5 Cover Open .................................................................................................... 40

2.6 Toner Low Detection....................................................................................... 41

3. PARTS REPLACEMENT........................................................................................ 43

3.1 Precautions for Parts Replacement................................................................ 43

3.2 Parts Layout.................................................................................................... 45

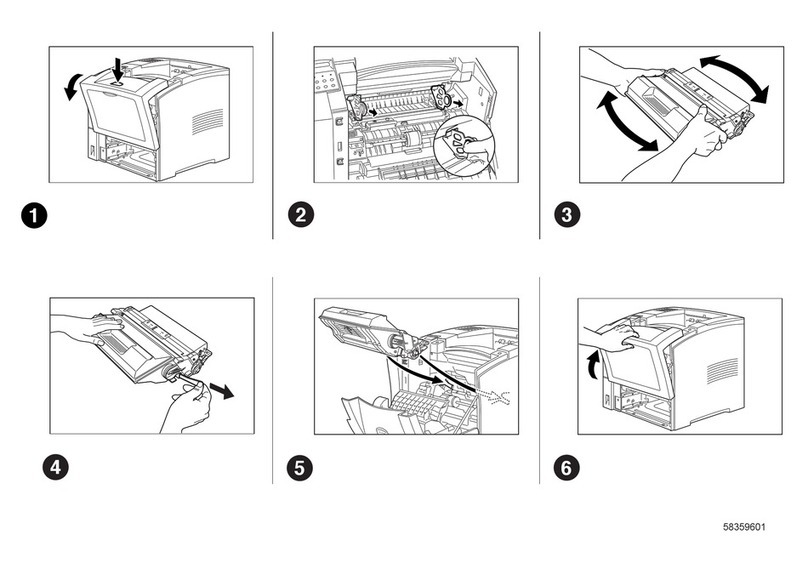

3.3 How to Change Parts...................................................................................... 48

3.3.1 Upper Cover Assy .................................................................................................... 49

3.3.2 LED Head ................................................................................................................. 50

3.3.3 Operator Panel Assy ................................................................................................ 51

3.3.4 Lower Base Unit ....................................................................................................... 52

3.3.5 Pulse Motor (Main/Drum) ......................................................................................... 53

3.3.6 Pulse Motor (Registration)........................................................................................ 54

3.3.7 Face Up Stacker Assy .............................................................................................. 55

3.3.8 Eject Roller Assy ...................................................................................................... 56

3.3.9 Motor Assy................................................................................................................ 57

3.3.10 Hopping Roller Shaft Assy........................................................................................ 58

3.3.11 Stacker Cover Assy.................................................................................................. 59

3.3.12 Registration Rolle ..................................................................................................... r60

3.3.13 Roller Transfer Assy ................................................................................................. 61

3.3.14 Fusing Unit ...............................................................................................................62

3.3.15 Back-up Roller .......................................................................................................... 63

3.3.16 Sensor Plate (Inlet)................................................................................................... 64

3.3.17 Sensor Plate (Outlet), Sensor Wire Assy ................................................................. 65

3.3.18 Manual Feed Guide Assy ......................................................................................... 66

3.3.19 Sensor Plate (Paper Supply) .................................................................................... 67

3.3.20 M7E-PCB.................................................................................................................. 68

3.3.21 Power Supply/Sensor Board, High Voltage Unit and Contact Assy ......................... 69

3.3.22 Cassette Guide L Assy............................................................................................. 70

3.3.23 Cassette Guide R Assy ............................................................................................ 71

3.3.24 Spacer Bearing (L/R)................................................................................................ 72