41260201TH Draft 4 /

CONTENTS

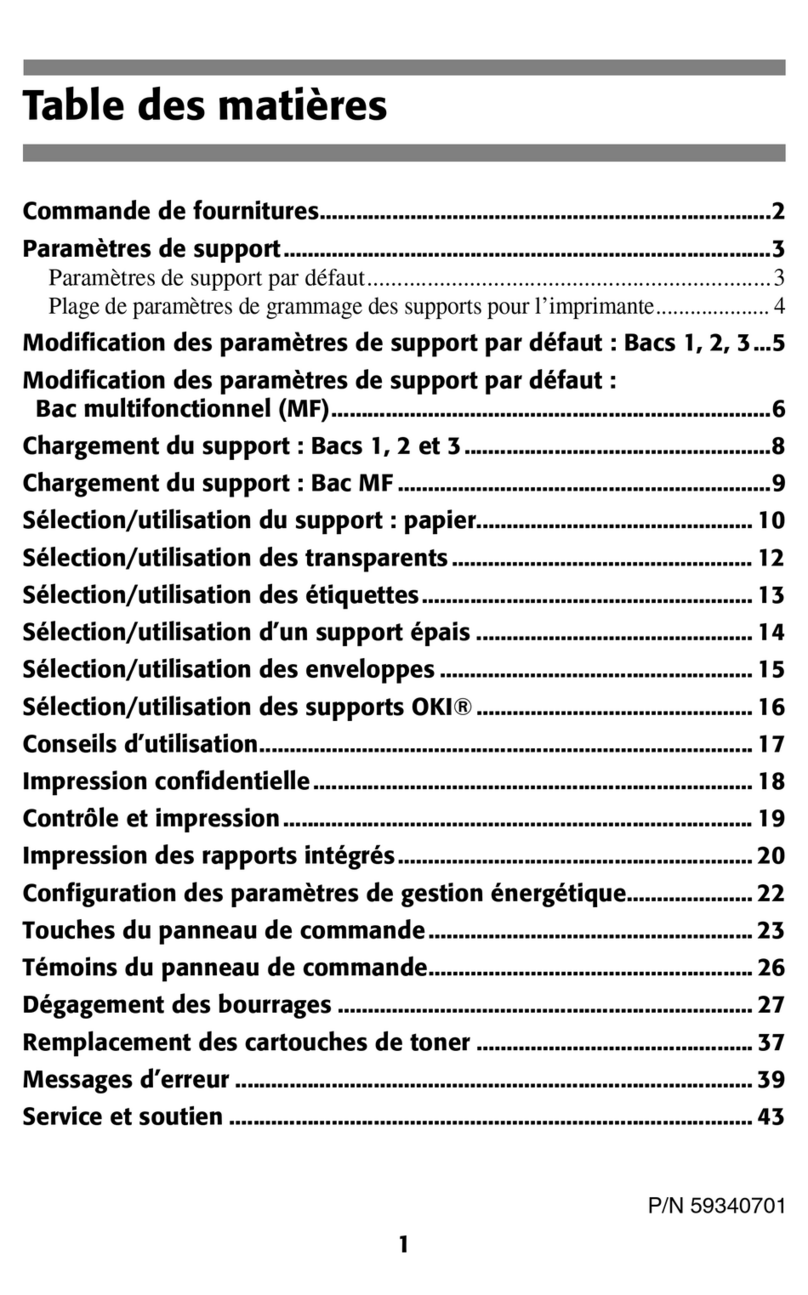

1. CONFIGURATION ......................................................................................... 6

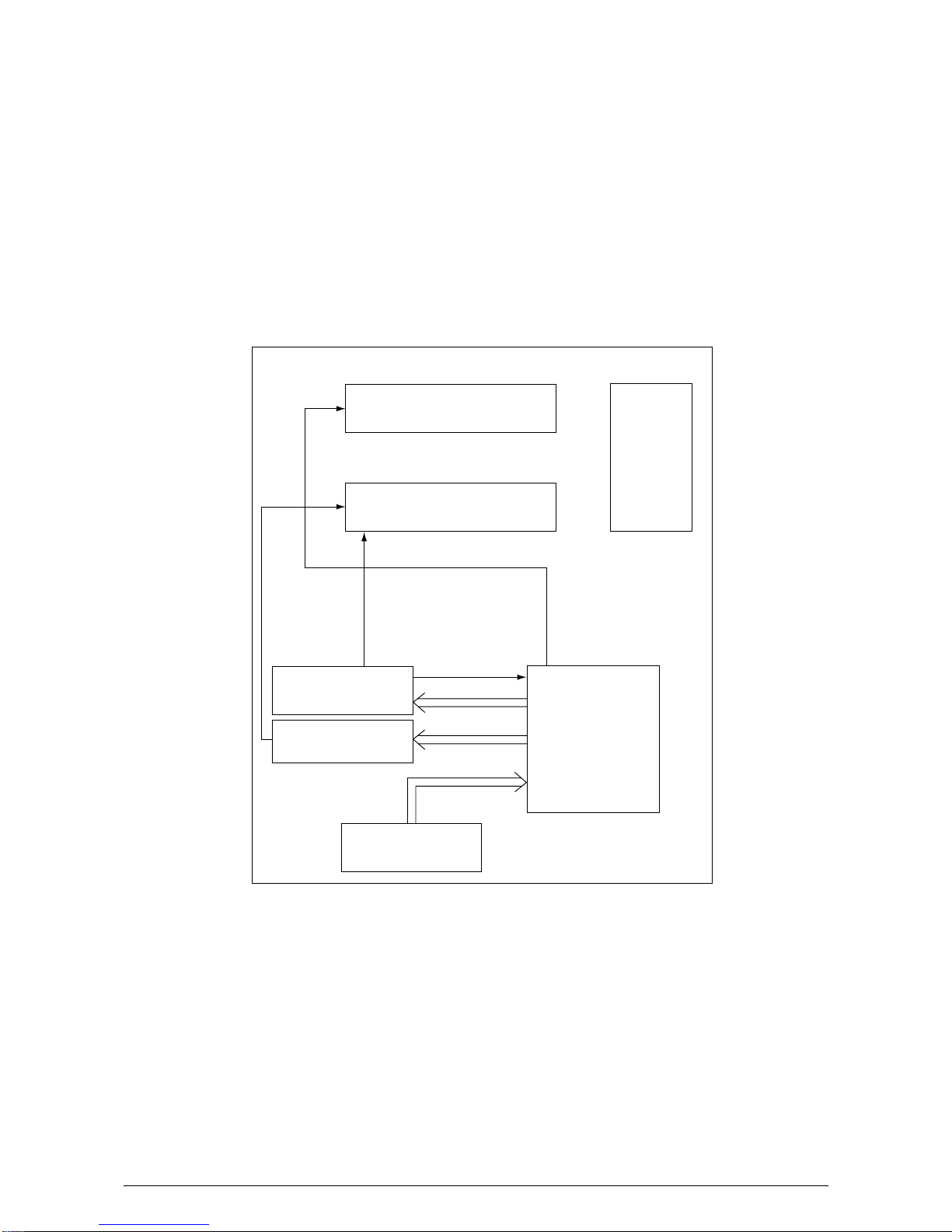

1.1 System Configuration ............................................................................... 6

1.2 Printer Configuration................................................................................. 7

1.3 Specification ............................................................................................. 8

1.4 Safety Standards ...................................................................................... 10

1.4.1 Certification Label............................................................................................ 10

1.4.2 Warning Label ................................................................................................. 10

2. OPERATION DESCRIPTION......................................................................... 11

2.1 Main Control Board................................................................................... 13

2.2 Power Supply Unit .................................................................................... 14

2.3 High-Voltage Power Supply Board ........................................................... 14

2.4 Electro-Photographic Processor............................................................... 16

2.5 Electro-Photographic Process .................................................................. 20

2.5.1 Explanation of Each Process Operation.......................................................... 22

2.6 Paper Jam Detection ................................................................................ 27

2.7 Toner Low Detection................................................................................. 29

2.8 Cover Open .............................................................................................. 31

2.9 Detecting I/D Unit existence ..................................................................... 31

3. PARTS REPLACEMENT ............................................................................... 34

3.1 Precautions for Parts Replacement.......................................................... 34

3.2 Parts Layout.............................................................................................. 36

3.3 Replacing Parts ........................................................................................ 39

3.3.1 Hopper Plate ................................................................................................... 39

3.3.2 LED Head and Head Spring............................................................................ 40

3.3.3 Transfer Roller................................................................................................. 41

3.3.4 How to remove Cover Upper Assy .................................................................. 42

3.3.5 Upper Cover Assy ........................................................................................... 43

3.3.6 High-Voltage Power Supply Board (P2H) ....................................................... 44

3.3.7 Top Cover Assy and Flat Cable Assy.............................................................. 45

3.3.8 Paper Holder ................................................................................................... 46

3.3.9 Side Plate M and Idle Gear ............................................................................. 47

3.3.10 Heat Assy ........................................................................................................ 48

3.3.11 Drive Shaft E (Eject) and Eject Roller ............................................................. 49

3.3.12 Pressure Roller B (Back Up Roller)................................................................. 50

3.3.13 Separator Guide .............................................................................................. 51

3.3.14 Pulse Motor (Main) .......................................................................................... 53

3.3.15 Hopping Shaft Assy......................................................................................... 54

3.3.16 Regist Roller.................................................................................................... 55

3.3.17 Paper Sensor E, Paper Sensor Exit and Toner Sensor Assy ......................... 56

3.3.18 Base Plate ....................................................................................................... 57

4. ADJUSTMENT ............................................................................................... 58

4.1 Adjustment Types and Functions ............................................................. 58

4.1.1 Printer Driver ................................................................................................... 58

4.1.2 Engine Maintenance Utility.............................................................................. 58