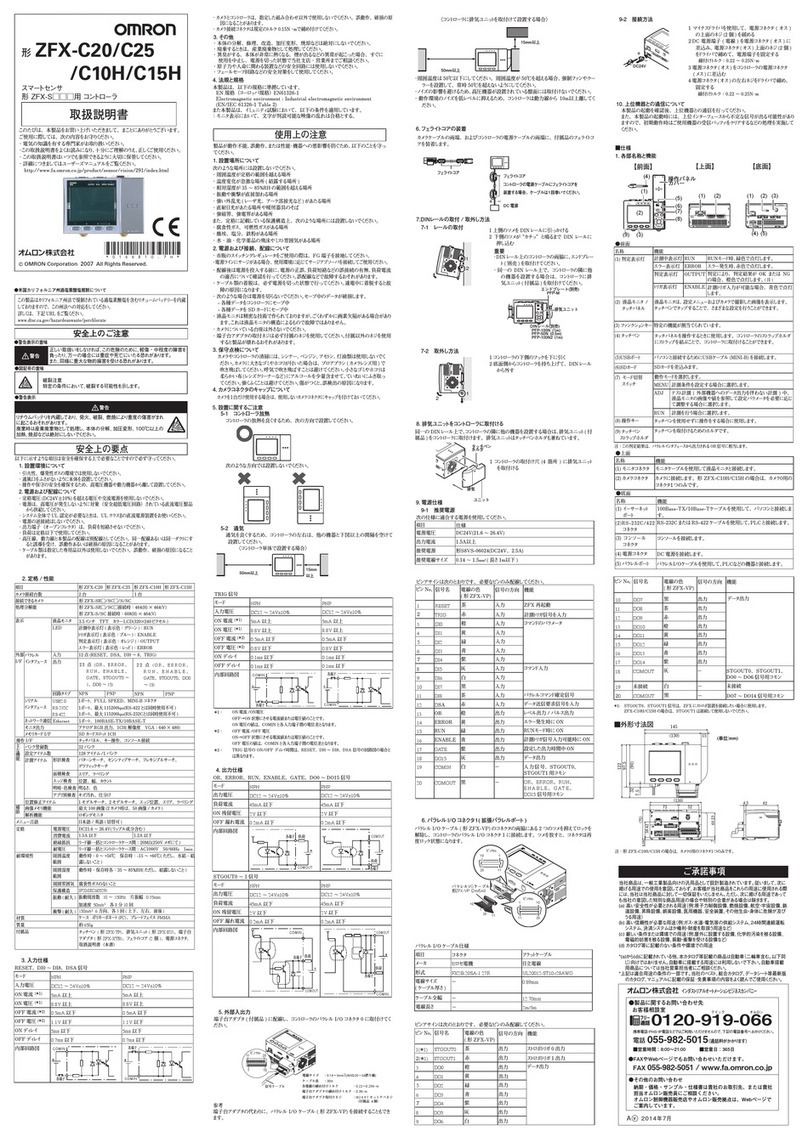

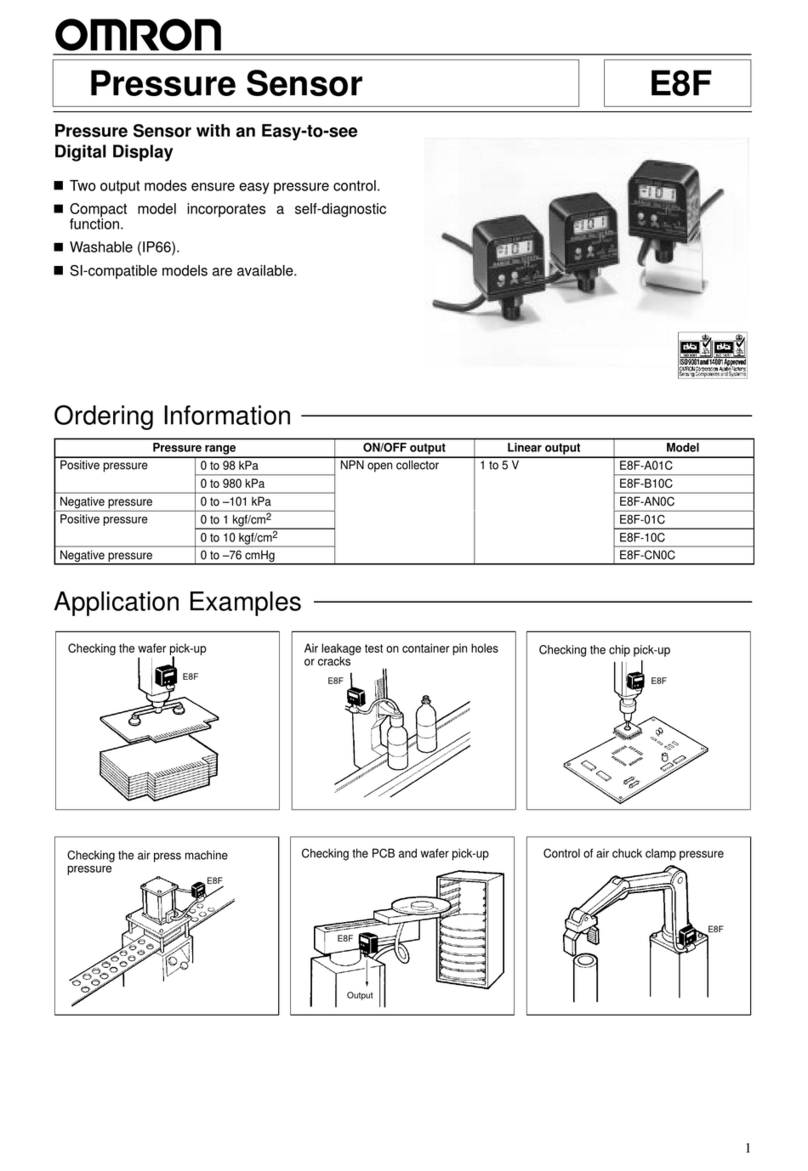

Classification Functions

Span adjuster

(Amplifier) The output is adjusted to approximately 8 V FS before shipping.

The span adjustment changes the ratio of the output current (displacement) to the distance. By using the

span adjustment, the actual current-distance relationship can be changed to either a higher output current at

the same distance or to a lower output current. When there are changes in material or color in the target

object, and a 1:1 ratio is not obtained, span adjustment is used to modify the current output level.

With the span adjuster, it is possible to adjust the full scale of the voltage (±30%) that is output when the

object is within the measurement range.

For the step-by step Operating/Adjusting procedure refer to

-- Span Adjustment

(in a subsequent section).

+30%

-30% +30%

-30%

Sensing

distance

(mm)

Sensing

distance

(mm)

Linear

output

(V)

Linear

output

(V)

Z4M-W40 Z4M-W100

Enable output

(Amplifier) The enable output is ON when the Sensor is performing a displacement measuring operation.

The enable output is OFF when there is no object in front of the Sensor or if the light reflected from the object

is insufficient or too intense.

An open collector output of 50 mA at 40 VDC maximum can be obtained.

In the case of measuring an metal or glossy object, the enable output may be ON even if the object is outside

the measurement range.

Linear output

(Amplifier) An analog voltage signal according to the measuring distance will be output from the output line (black shield

wire).

Voltage output: -4 to 4 V/30 to 50 mm (Z4M-W40), -4 to 4 V/60 to 140 mm (Z4M-W100)

Output impedance: 100 Ω(typical)

The linear output will be locked between 6 and 8 V when the enable output is OFF.

Laser OFF input

(Amplifier) The laser OFF input controls laser emission.

Laser emission is turned on when there is no laser OFF input (with a current leakage of 0.1 mA max.) and it is

turned off when the laser OFF input is short-circuited to the 0-V terminal (with a residual voltage of 2 V max.).

When laser emission is turned Off, the linear output, indicators, and the enable output of the Sensor are on

hold.

There will be a drift of 0.1% FS/s when the analog output of the Sensor is on hold.

The response time required to turn laser emission ON or OFF is 3 ms max.

Laser emission

delaying function

(Sensor and Amplifier)

When the Sensor is turned ON, the range indicators (green) will blink for 3 to 10 s, alerting the user to laser

emission; during this time the linear output is locked between 6 and 8 V. After this time, the laser beam will be

turned ON.

OPERATIONAL EXAMPLES: Z4M SENSOR AND K3TS INTELLIGENT DIGITAL PANEL METER

Measurement distance (set to 40 mm)

Timing input

Deflection value = maximum value - minimum value

K3TS

Note: Use a pushbutton switch to turn ON the timing

input while measuring eccentricity.

Measuring Eccentricity

Using the scaling function, it is possible to convert the

Sensor’s output (±4 V) into the actual measured dimension

of the object for display.

By selecting the appropriate measurement mode that corre-

sponds to the application, necessary data can be easily ob-

tained. In the following application, the peak-to-peak hold

mode is used to measure the eccentricity of an object by

measuring the difference between the maximum and

minimum values while the timing input is ON.

Z4M Z4M