6ZX2 User’s Manual

INTRODUCTION

MAIN

APPLICATIONS

& SETTING

METHODS

SPECIFI-

CATIONS

INDEX

SETTING

TRANSITION

CHARTS

DETAILED

SETTINGS

FLOW OF

OPERATION

CONTENTS

PREPARATION

FOR

MEASUREMENT

BASIC

SETUP

TROUBLE-

SHOOTING

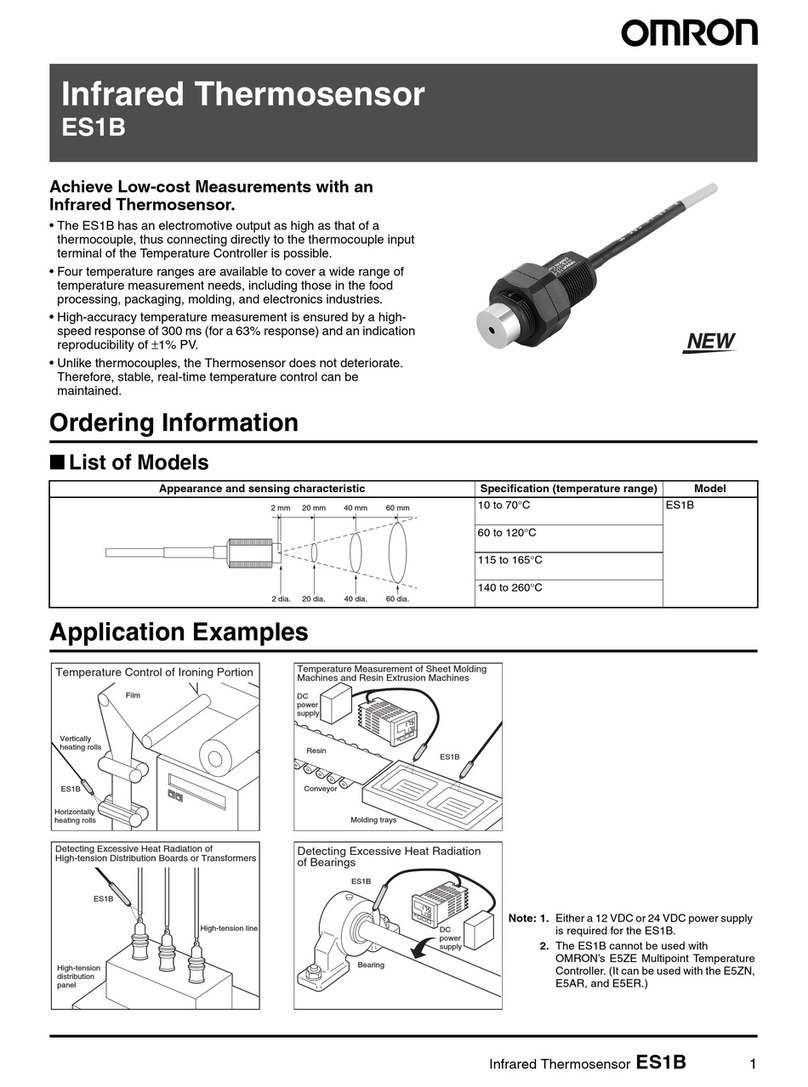

Height

Double

Sheet

Detection

Positioning

Eccentricity

and Surface

Deflection

Steps

and

Warpage

Thickness

At the customer’s request, OMRON will provide applicable third party certification

documents identifying ratings and limitations of use that apply to the products. This

information by itself is not sufficient for a complete determination of the suitability of the

products in combination with the end product, machine, system, or other application or

use.

The following are some examples of applications for which particular attention must be

given. This is not intended to be an exhaustive list of all possible uses of the products, nor

is it intended to imply that the uses listed may be suitable for the products:

Outdoor use, uses involving potential chemical contamination or electrical interference, or

conditions or uses not described in this document.

Nuclear energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment, and

installations subject to separate industry or government regulations.

Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO

LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS

BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in

determining suitability and does not constitute a warranty. It may represent the result of

OMRON’s test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of

Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on

improvements and other reasons.

It is our practice to change model numbers when published ratings or features are

changed, or when significant construction changes are made. However, some

specifications of the product may be changed without any notice. When in doubt, special

model numbers may be assigned to fix or establish key specifications for your application

on your request. Please consult with your OMRON representative at any time to confirm

actual specifications of purchased products.