K3GN

K3GN

2

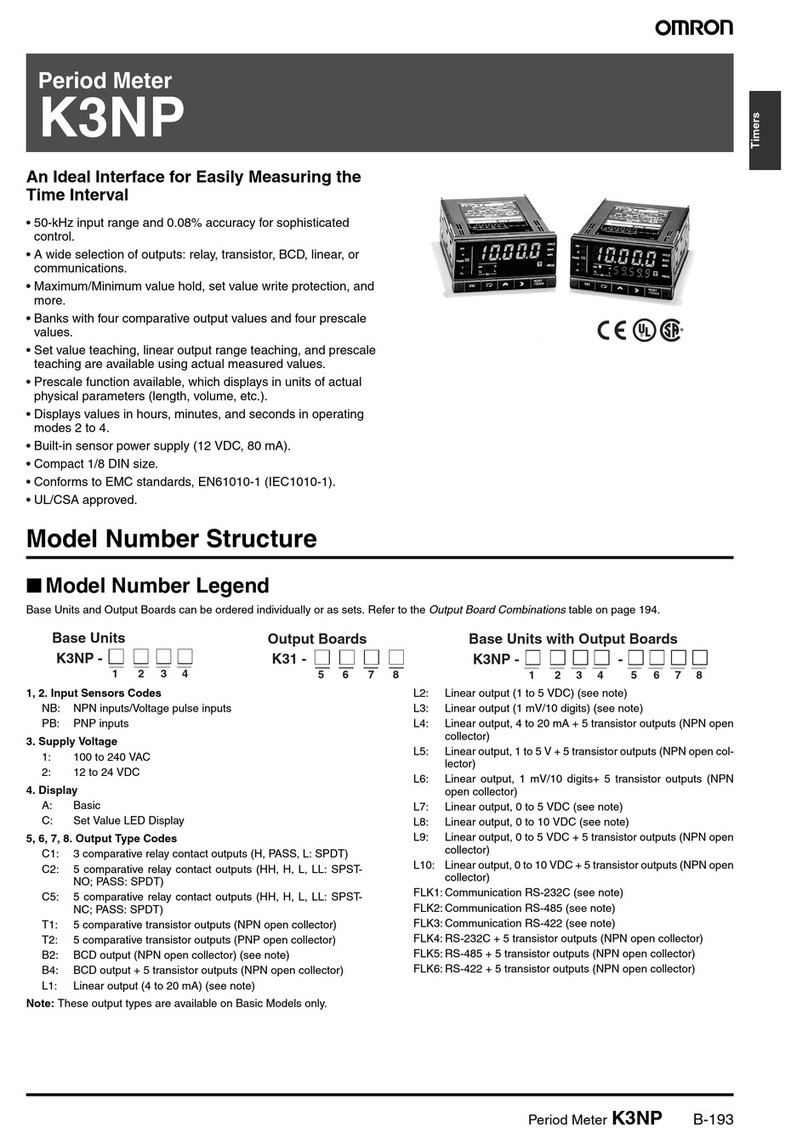

3MODEL NUMBER LEGEND

K3GN - - 24 VDC

12 3

1. Input Type

ND: DC voltage/current, NPN

PD: DC voltage/current, PNP

2. Output Type

C: 2 relay contact outputs (SPST-NO)

T1: 3 transistor outputs (NPN open collector)

T2: 3 transistor outputs (PNP open collector)

3. Communications Output Type

None: Communications not supported

FLK: RS-485

Specifications

3RATINGS

Supply voltage 24 VDC

Operating voltage range 85% to 110% of the rated supply voltage

Power consumption (See Note) 2.5 W max. (at max. DC load with all indicators lit)

Insulation resistance 20 MΩmin. at 500 VDC between external terminal and case.

Insulation provided between inputs, outputs, and power supply.

Dielectric withstand voltage 1,000 VAC for 1 min between external terminal and case.

Insulation provided between inputs, outputs, and power supply.

Noise immunity ±480 V on power supply terminals in normal mode, ±1,500 V in common mode,

±1µs, or 100 ns for square-wave noise with 1 ns

Vibration resistance Malfunction 10 to 55 Hz, 10 min each in X, Y, and Z directions; acceleration: 9.8 m/s2

Destruction 10 to 55 Hz, 30 min each in X, Y, and Z directions; acceleration: 19.6 m/s2

Shock resistance Malfunction Models with transistor outputs: 196 m/s2for 3 times each in X, Y, and Z directions

Models with relay contact outputs: 98 m/s2for 3 times each in X, Y, and Z directions

Destruction 294 m/s2for 3 times each in X, Y, and Z directions

Ambient temperature Operating -- 1 0°Cto55

°C(14

°F to 131°F) with no condensation or icing

Storage -- 2 5°Cto65

°C(--13

°F to 149°F) with no condensation or icing

Ambient humidity Operating 25% to 85% with no condensation

Ambient atmosphere Must be free of corrosive gas

EMC Emission Enclosure EN55011 Group 1 class A

Emission AC Mains EN55011 Group 1 class A

Immunity ESD EN61000-4-2: 4-kV contact discharge (level 2)

8-kV air discharge (level 3)

Immunity-RF-interference ENV50140: 10 V/m (amplitude modulated, 80 MHz to 1 GHz) (level 3)

10 V/m (pulse modulated, 900 MHz)

Immunity Conducted Disturbance ENV50141: 10 V (0.15 to 80 MHz) (level 3)

Immunity Burst EN61000-4-4: 2-kV power-line (level 3)

2-kV I/O signal-line (level 4)

Approved standards UL Listed, File No. E41515 to UL508 standard

CSA Certified, File No. LR67027 to CSA22.2 No. 142--M1987 standard

Conforms to EN50081-2, EN50082-2, EN61010-1 (IEC1010-1); conforms to

VDE106/part 100 (finger protection) when the terminal cover is mounted.

Weight Approx. 100 g

Note: A control power supply capacity greater than the rated capacity is required when the Digital Panel Meter is turned ON. Do not for-

get to take this into consideration when using several Digital Panel Meters. When power is supplied, all indicators will light and

outputs will be OFF. When using startup compensation time operation, the display will read “ööööö” and all outputs will be OFF.