Omron SYSMAC Series Use and care manual

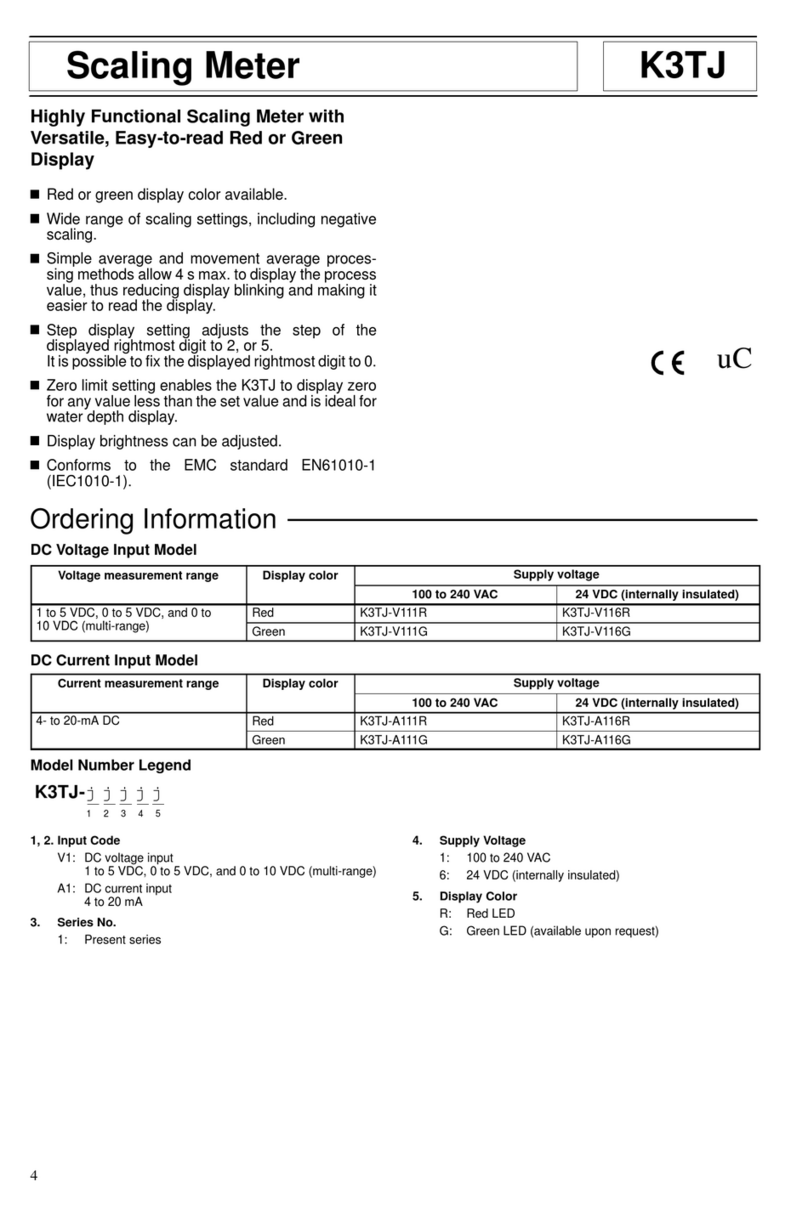

Other Omron Measuring Instrument manuals

Omron

Omron K6PM-TH User guide

Omron

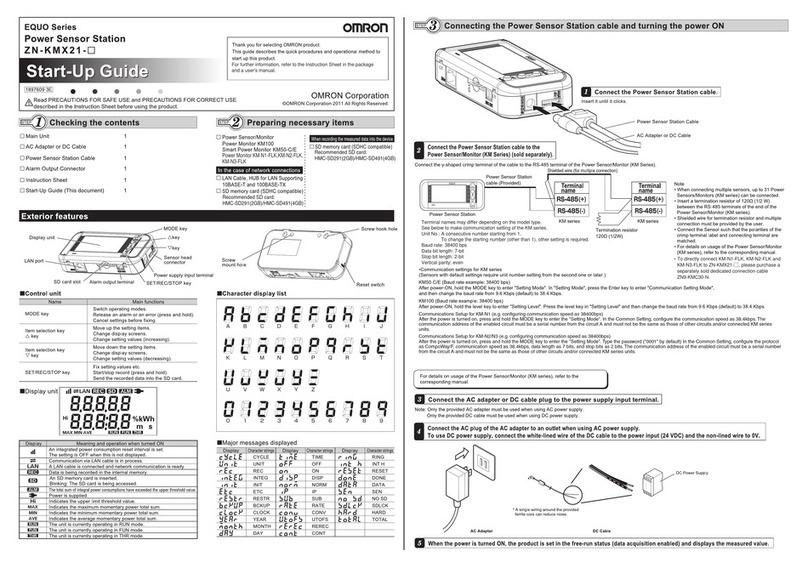

Omron EQUO Series User guide

Omron

Omron H7CX-N - User manual

Omron

Omron K3MA-J Series User manual

Omron

Omron K3NR User manual

Omron

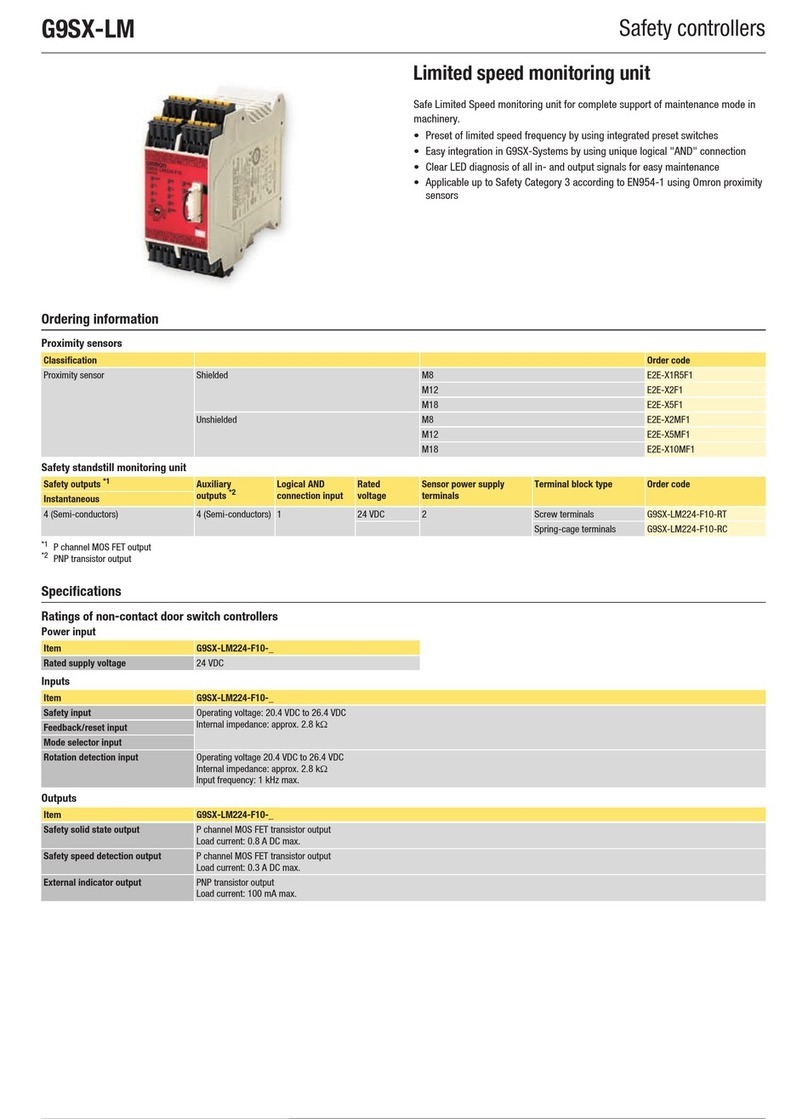

Omron G9SX-LM User manual

Omron

Omron STC-FDR-SW01 User manual

Omron

Omron K3HB-X User manual

Omron

Omron Sti G9SX-SM032 Series User manual

Omron

Omron H7CC-A Series User manual

Omron

Omron G9SX Series User manual

Omron

Omron K7DD User manual

Omron

Omron K3NC User manual

Omron

Omron K7DD User manual

Omron

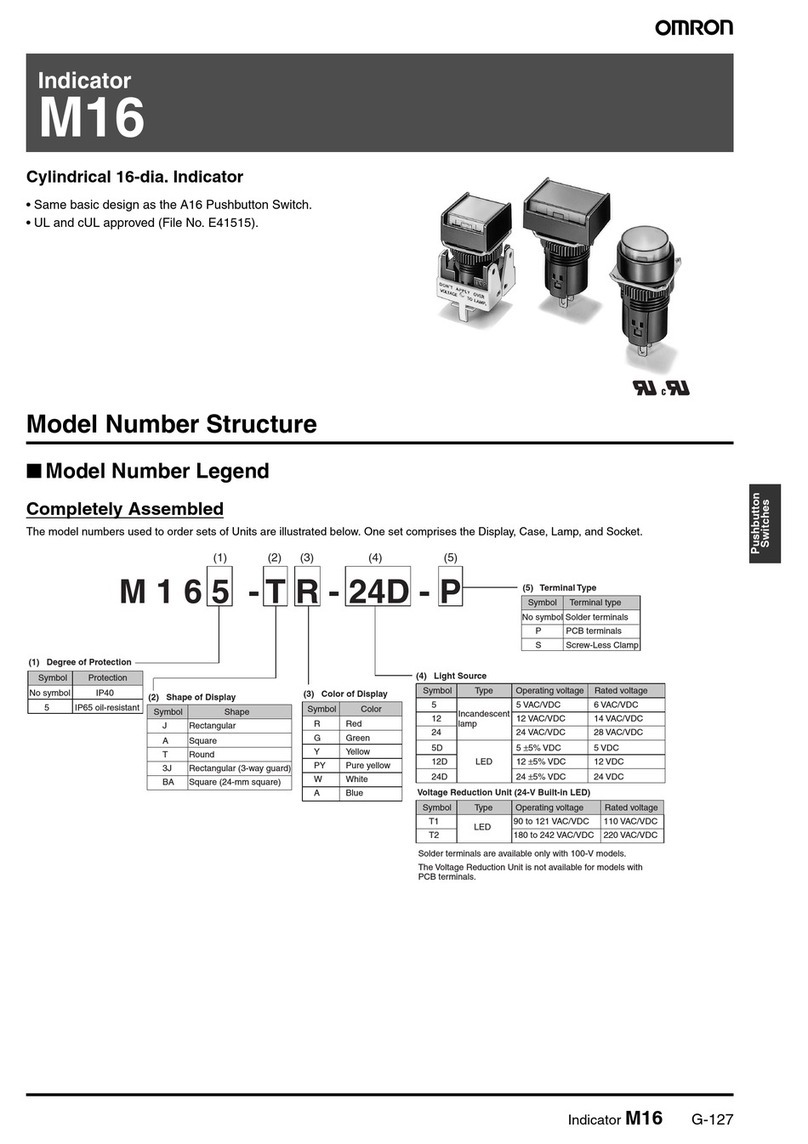

Omron M16 - User manual

Omron

Omron H7E User manual

Omron

Omron EQUO Series User manual

Omron

Omron Z500 Series User manual

Omron

Omron H7CX-R11-N User manual

Omron

Omron K6PM-TH User manual