ix

About this Manual:

This manual describes the installation and operation of the E5ZN-DRT DeviceNet Communications

Unit for E5ZN Temperature Controllers and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the E5ZN-DRT DeviceNet Communications Unit. Be sure to read the

precautions provided in the following section.

Precautions provides general precautions for using the E5ZN-DRT DeviceNet Communications Unit,

Programmable Controller, and related devices.

Section 1 introduces the features and system configuration of the E5ZN-DRT DeviceNet Communica-

tions Unit, the types of E5ZN Temperature Controller that can be used, and other basic information.

Section 2 outlines the basic operating procedures of the E5ZN-DRT DeviceNet Communications Unit.

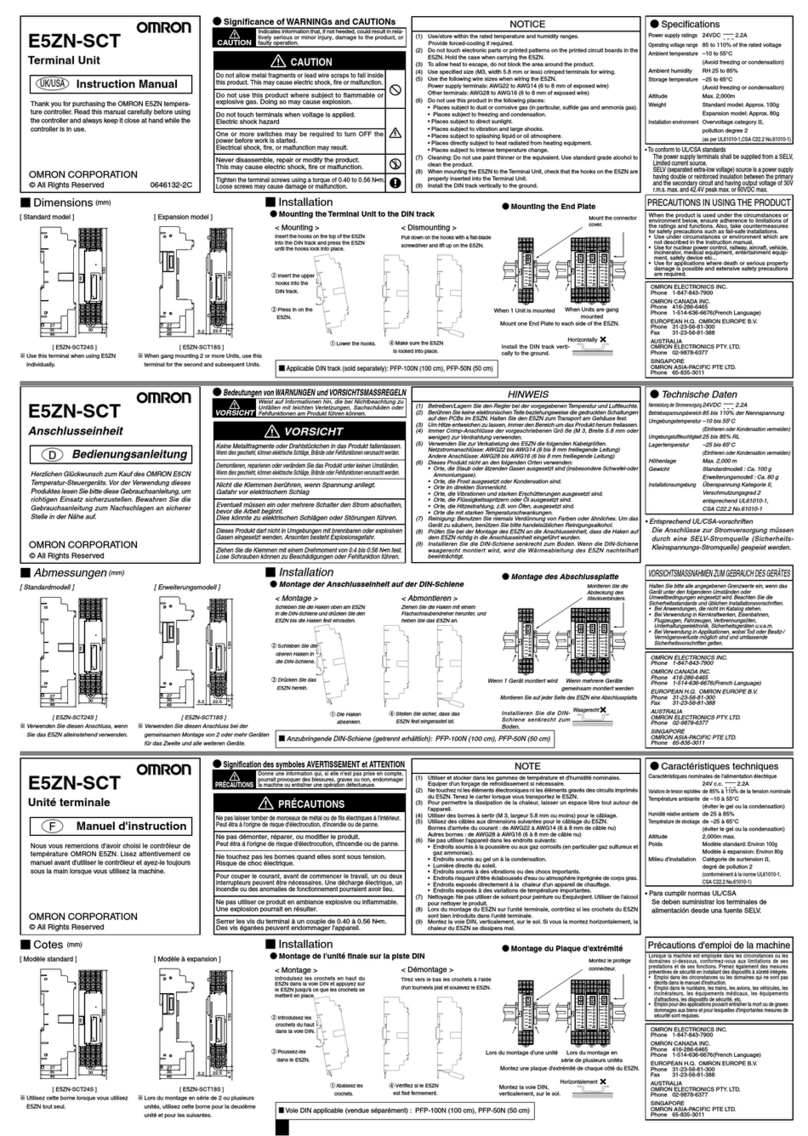

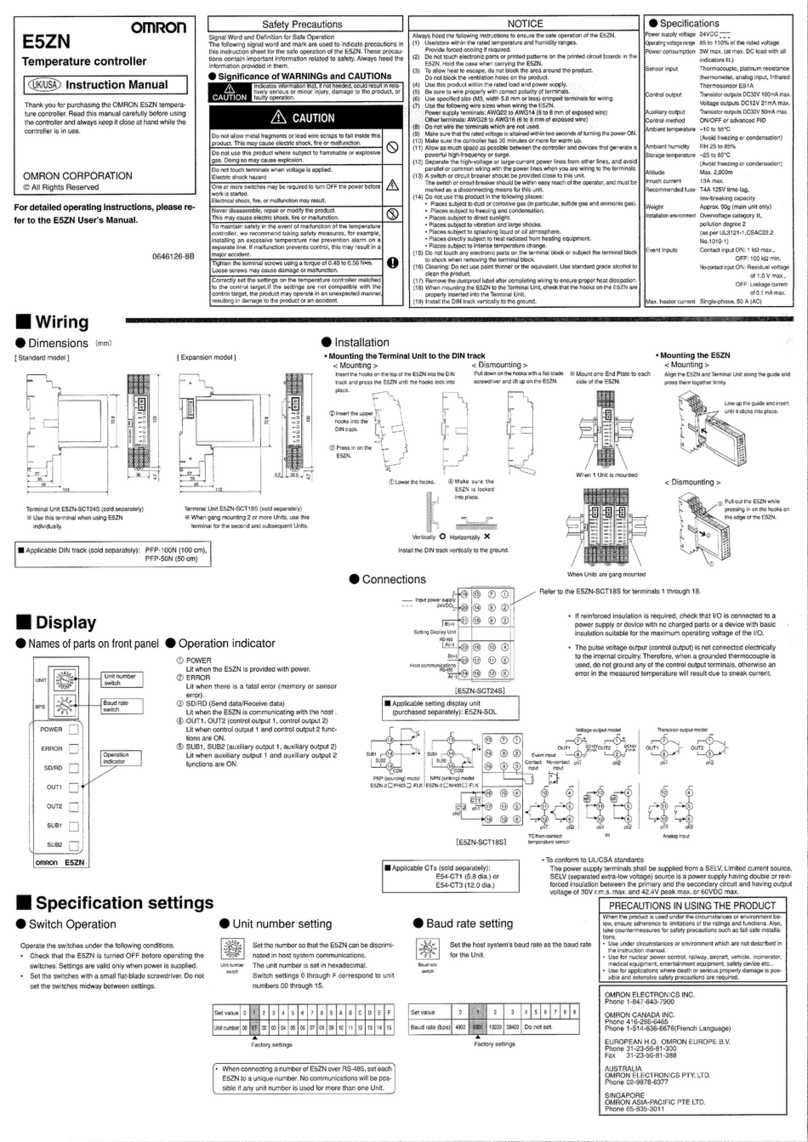

Section 3 describes the methods used to install and wire the E5ZN-DRT DeviceNet Communications

Unit and the E5ZN Temperature Controller. The settings of DeviceNet Communications Unit switches

are also described.

Section 4 describes the input (IN) areas and output (OUT) areas that E5ZN-DRT DeviceNet Commu-

nications Units can use for remote I/O communications. The methods to allocate data for master com-

munications are also described.

Section 5 describes the DeviceNet Configurator operations that can be used for the E5ZN-DRT

DeviceNet Communications Unit except for allocation procedures, which are described in SECTION 4

Remote I/O Communications.

Section 6 describes how to send explicit messages to the E5ZN-DRT DeviceNet Communications

Unit, including how to send CompoWay/F commands using explicit messages. CompoWay/F com-

mands are supported by the E5ZN Temperature Controller.

Section 7 provides information on the time required for a complete communications cycle, for an out-

put response to be made to an input, to start the system, and to send messages.

Section 8 describes error processing, periodic maintenance operations, and troubleshooting proce-

dures needed to keep the DeviceNet Network operating properly. Details on resetting replaced Units

are also provided. Read through the error processing procedures in both this manual and the operation

manual for the DeviceNet master being used before operation so that operating errors can be identified

and corrected more quickly.

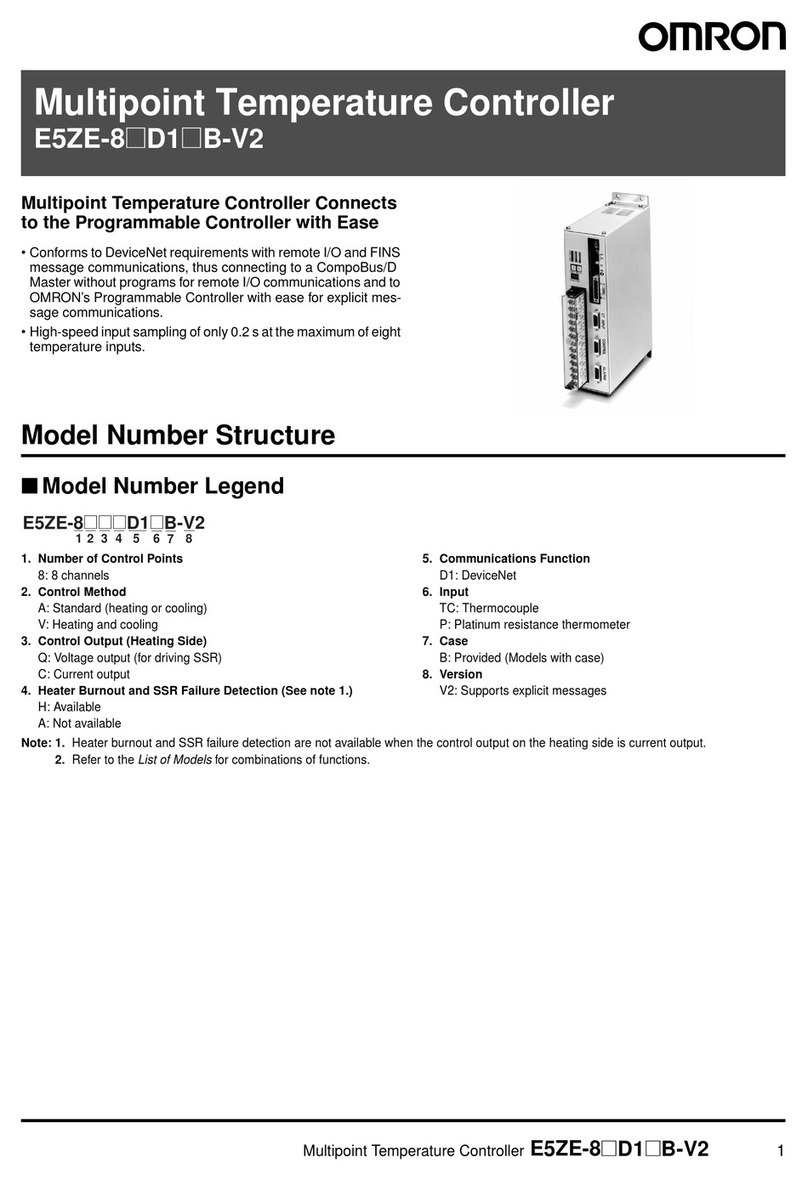

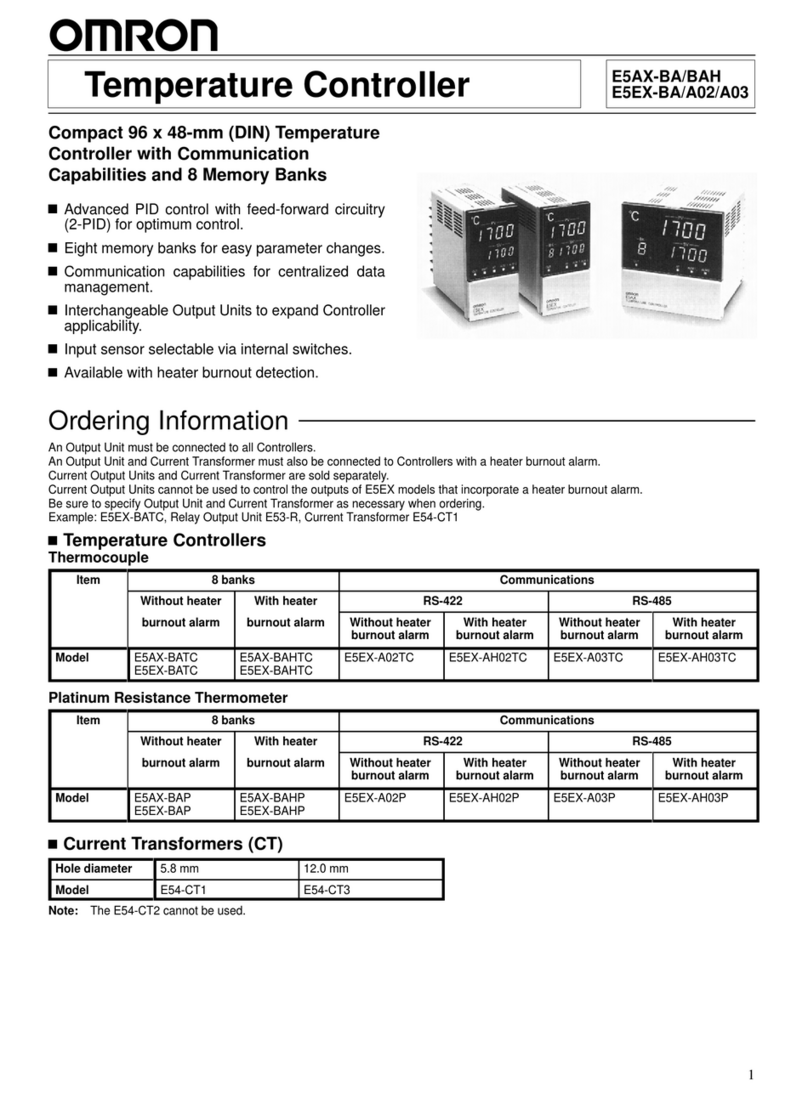

The Appendices provide the handling methods for EDS setting files required for multivender environ-

ments, the device profile of the E5ZN-DRT DeviceNet Communications Unit, and information on

related products.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.