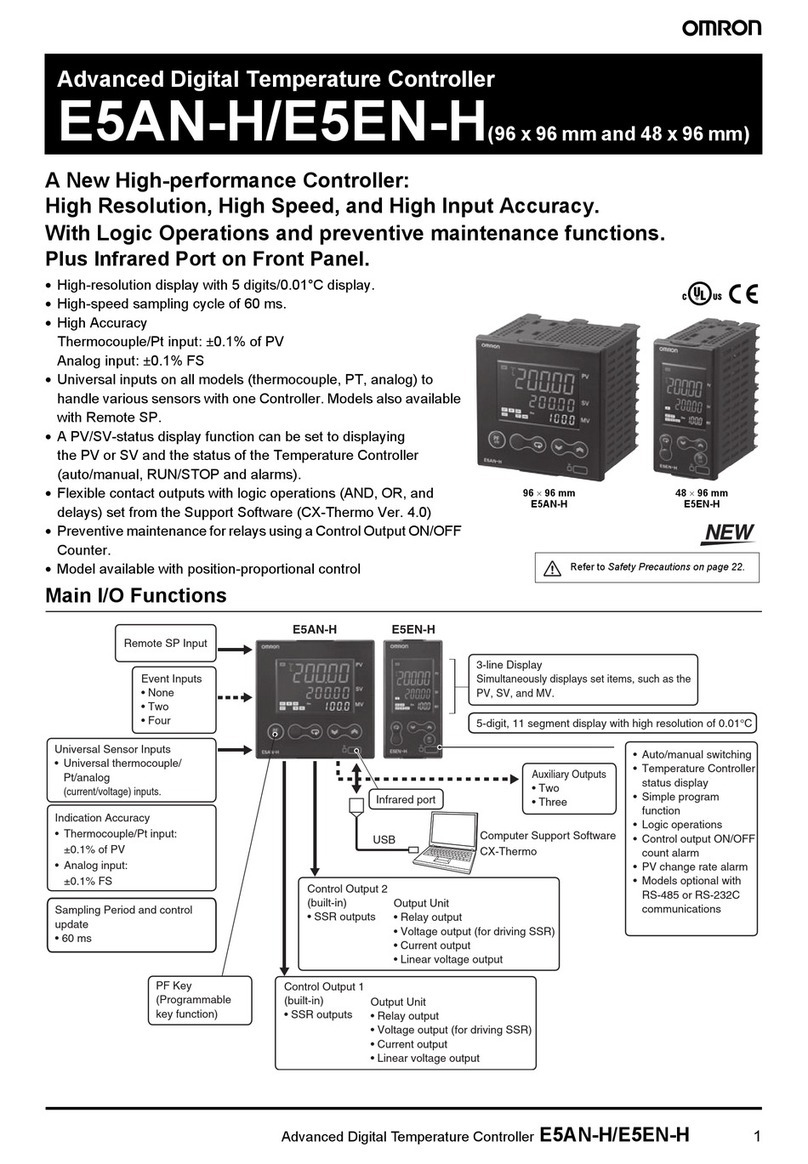

Omron E5*N Series Installation guide

Other Omron Temperature Controllers manuals

Omron

Omron E5EX-H User manual

Omron

Omron E5CC-800 User manual

Omron

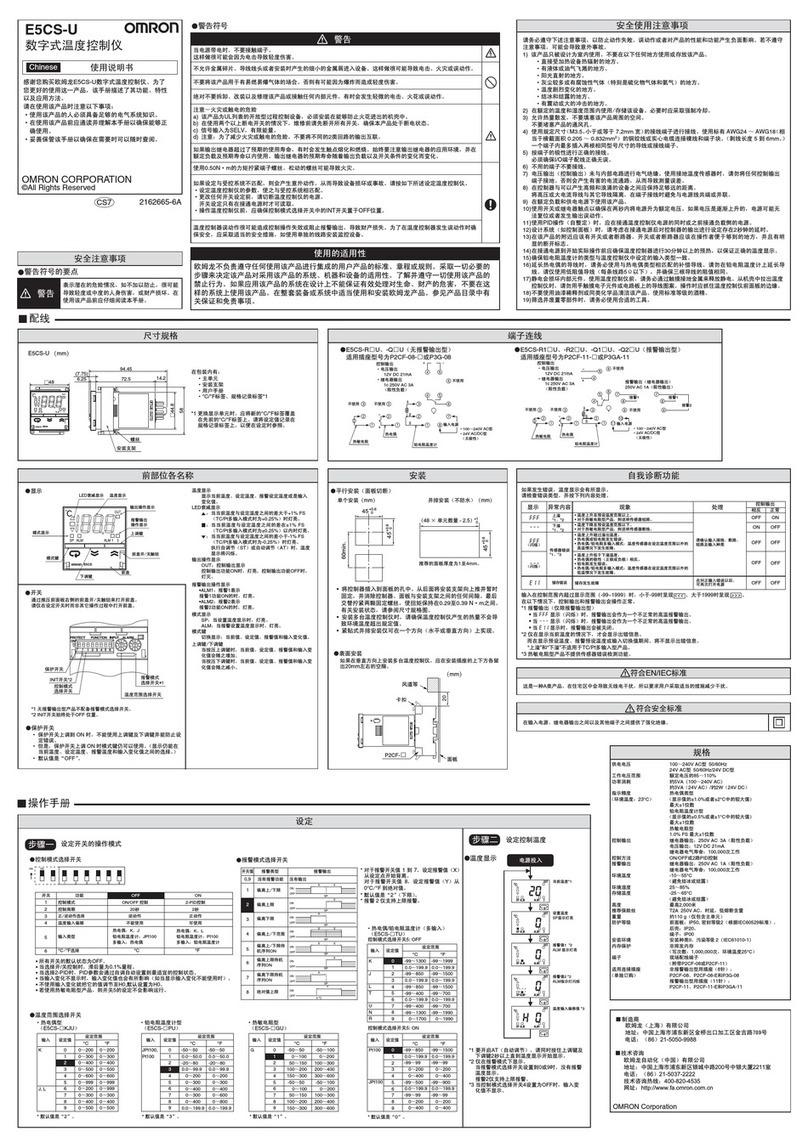

Omron E5CS-U User manual

Omron

Omron E5CS-X - User manual

Omron

Omron E5ZN Series User manual

Omron

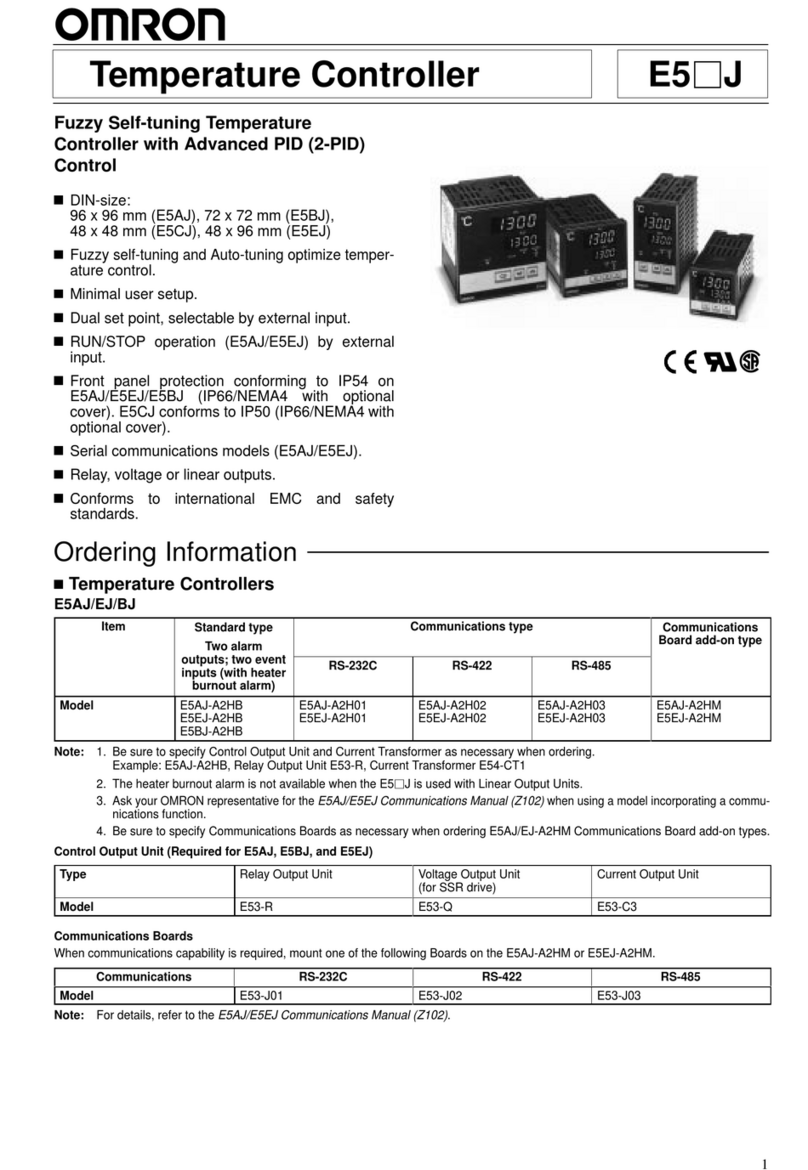

Omron E5 J Series User manual

Omron

Omron EJ1 EtherCAT User manual

Omron

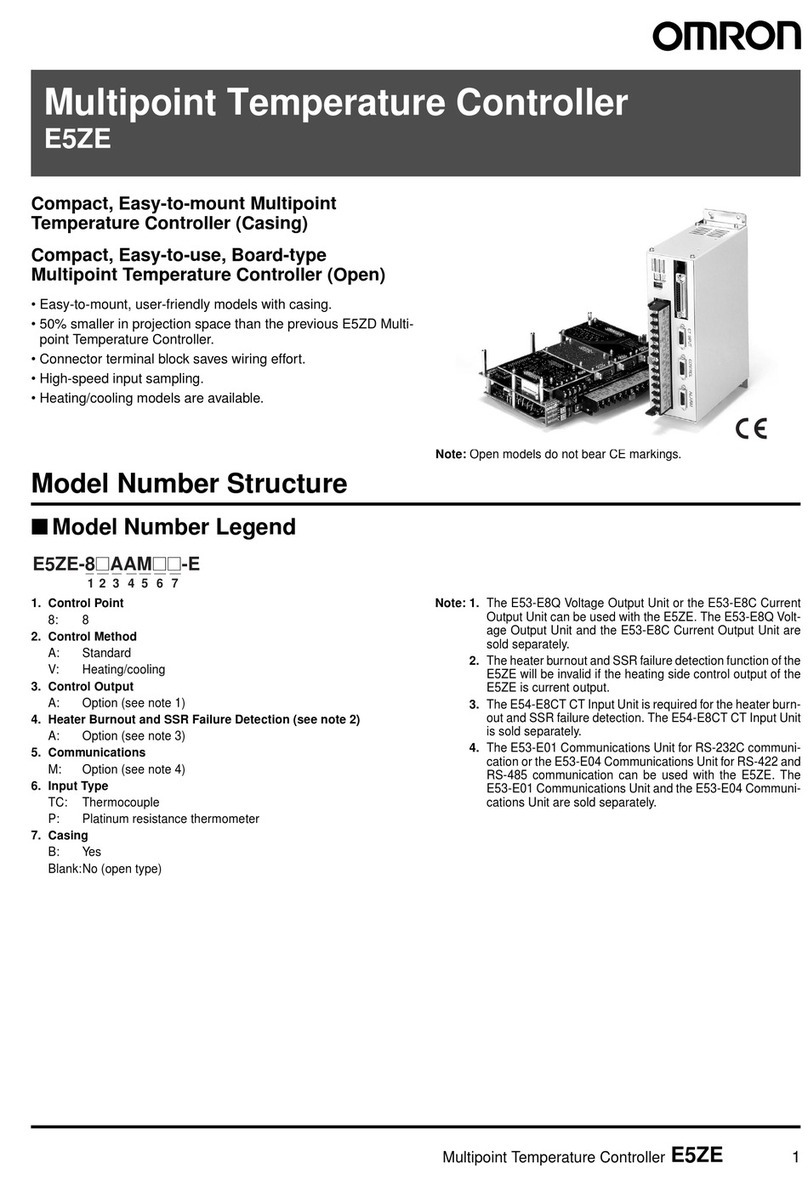

Omron E5ZE User manual

Omron

Omron E5ZE User manual

Omron

Omron EJ1 EtherCAT User manual

Omron

Omron E5EWL User manual

Omron

Omron E5CN User manual

Omron

Omron E5GN User manual

Omron

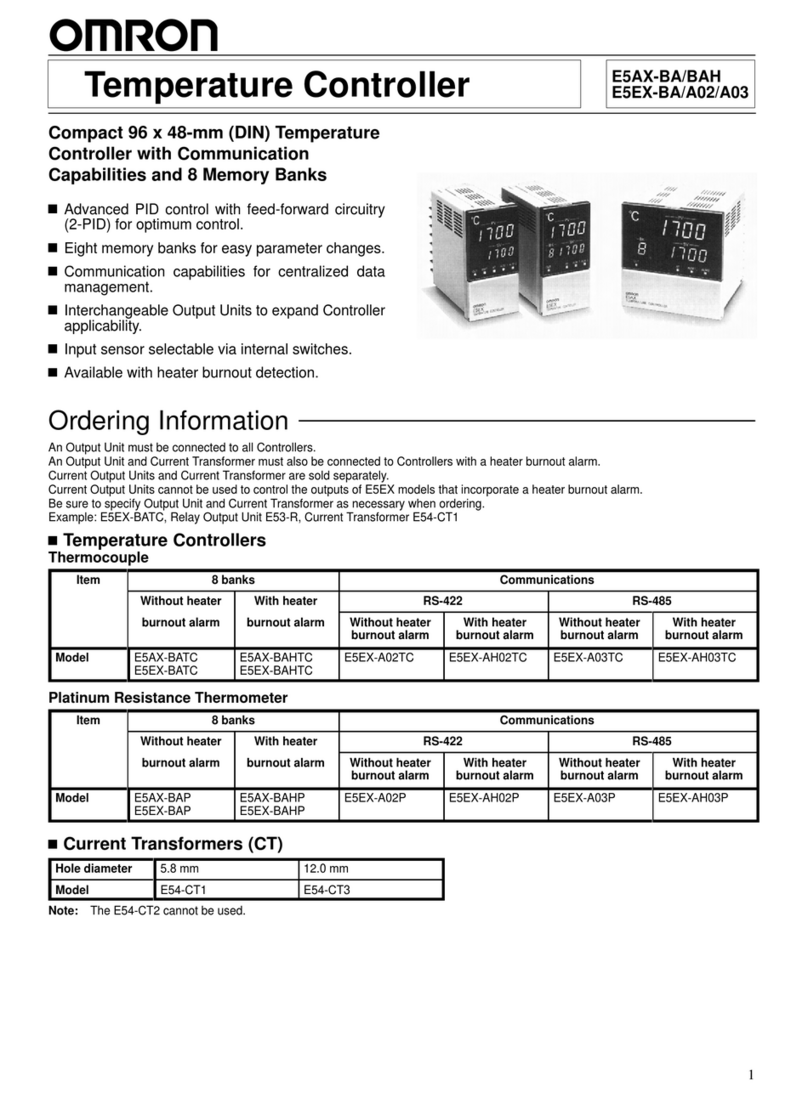

Omron E5AX-BA Series User manual

Omron

Omron E5ZE-8 E Series User manual

Omron

Omron C200H-TV Series User manual

Omron

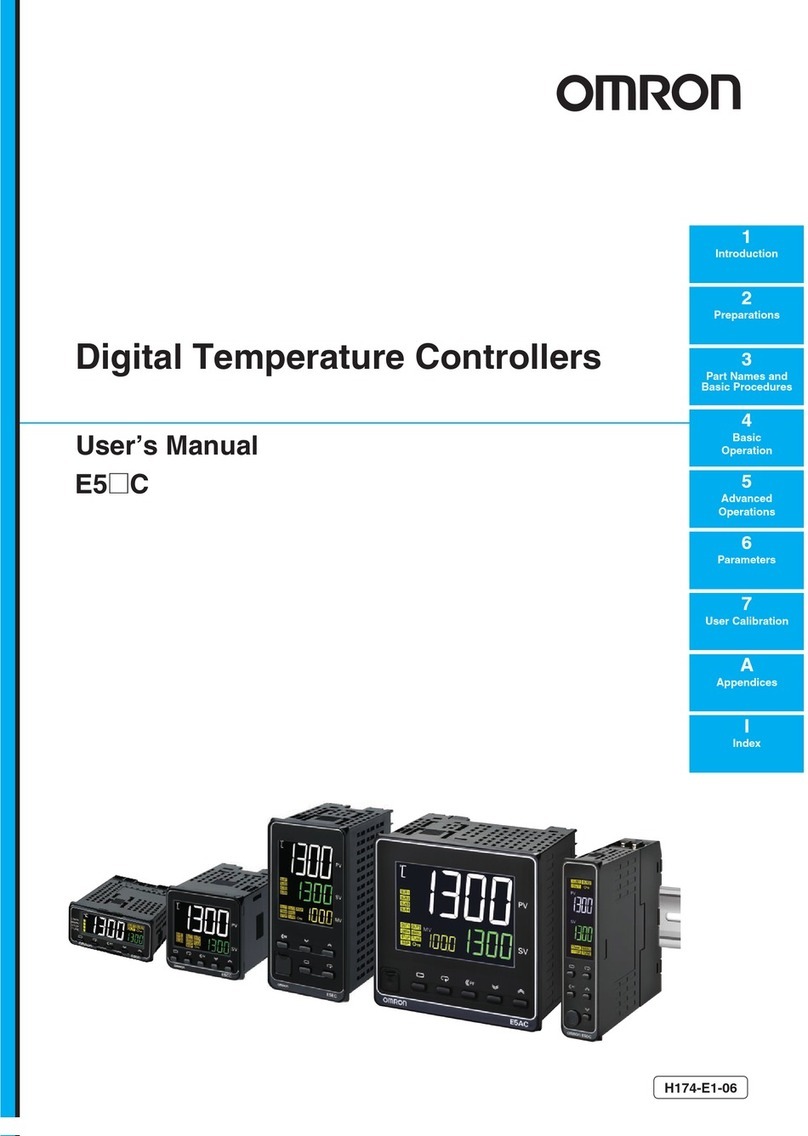

Omron E5C series User manual

Omron

Omron EJ1 EtherCAT User manual

Omron

Omron EJ1 EtherCAT User manual

Omron

Omron E5AC-T User manual

Popular Temperature Controllers manuals by other brands

P.W. KEY

P.W. KEY rt-208gt operating manual

BH Thermal

BH Thermal BriskONE owner's manual

West Control Solutions

West Control Solutions KS 45 Operation Notes

MCS

MCS RITC-15B Operator's manual

SMC Networks

SMC Networks Thermo-con INR-244-639 Operation manual

eltherm

eltherm Ex-TC It Series operating instructions