Contents

1. Introduction.................................................................................................................................... 4

1.1. Important Safety Notice....................................................................................................................4

1.2. Scope of the Manual........................................................................................................................ 4

1.2.1. Gecko SP1/3/5.........................................................................................................................4

1.3. Copyright............................................................................................................................................. 4

2. Safety..............................................................................................................................................5

2.1. Intended Use......................................................................................................................................5

2.2. General Safety Instructions........................................................................................................... 5

2.3. Risk Assessment.............................................................................................................................. 6

2.4. Environmental Safety.......................................................................................................................7

3. HW Installation.............................................................................................................................. 8

3.1. Overview..............................................................................................................................................8

3.2. Robot Mount...................................................................................................................................... 8

3.2.1. Optional - Angle Bracket.....................................................................................................8

3.2.2. Quick Changer Mounting...................................................................................................9

3.2.2.1. Quick Changer - Robot Side.................................................................................. 9

3.2.2.2. Gecko SP1/3/5.......................................................................................................... 9

3.2.3. Tools........................................................................................................................................ 9

3.2.3.1. Gecko SP1/3/5............................................................................................................9

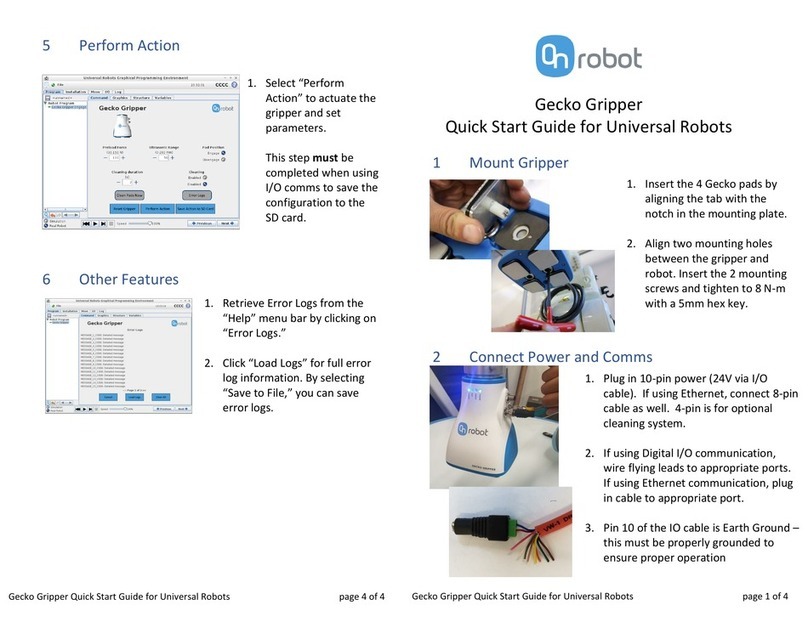

4. SW Installation..............................................................................................................................11

4.1. Gecko SP1/3/5 SW Installation.......................................................................................................11

5. Operation......................................................................................................................................12

5.1. Gecko SP Operation....................................................................................................................... 12

5.1.1. How the Gecko SP Works.................................................................................................. 12

5.1.2. TCP Setup..............................................................................................................................14

5.2. URScript Commands......................................................................................................................15

5.2.1. Gecko SP1/3/5...................................................................................................................... 15

5.2.1.1. Grip and Release...................................................................................................... 15

6. Hardware Specification.............................................................................................................. 16

6.1. Technical Sheets..............................................................................................................................16

6.1.1. Gecko SP1/3/5....................................................................................................................... 16

6.2. Mechanical Drawings................................................................................................................... 20

6.2.1. Adapter Plate.......................................................................................................................20

6.2.2. Angle Bracket......................................................................................................................21

6.2.3. Mountings............................................................................................................................22

6.2.3.1. Quick Changer - Robot Side................................................................................22

6.2.3.2. Quick Changer for I/O - Robot Side..................................................................23

6.2.4. Tools......................................................................................................................................23

2