RG2 User Manual –version 1.44

Specifications is periodically reviewed and may change without notice Copyright © 2015 –2016 by On Robot ApS. All rights reserved

Content

1Preface....................................................................................................... 1

1.1 Scope of delivery.................................................................................................. 1

1.2 Important safety notice......................................................................................... 1

2Introduction ................................................................................................ 2

3Safety instructions...................................................................................... 2

3.1 Validity and responsibility..................................................................................... 2

3.2 Limitations of liability............................................................................................ 2

3.3 Warning symbols in this manual........................................................................... 3

3.4 General warnings and cautions............................................................................ 4

3.5 Intended use ........................................................................................................ 5

3.6 Risk assessment.................................................................................................. 5

4Mechanical interface .................................................................................. 6

4.1 Mounting the gripper ............................................................................................ 6

4.2 Mechanical dimensions........................................................................................ 7

4.3 Load capacity....................................................................................................... 8

4.4 Fingers................................................................................................................. 8

4.5 Gripper Work Range............................................................................................ 9

4.5.1 Finger thickness ....................................................................................................................9

4.5.2 Gripping speed .....................................................................................................................9

5Electrical interface.................................................................................... 10

5.1 Tool connections................................................................................................ 10

5.1.1 Power supply..................................................................................................................... 10

6Technical.................................................................................................. 11

6.1 Technical Specifications..................................................................................... 11

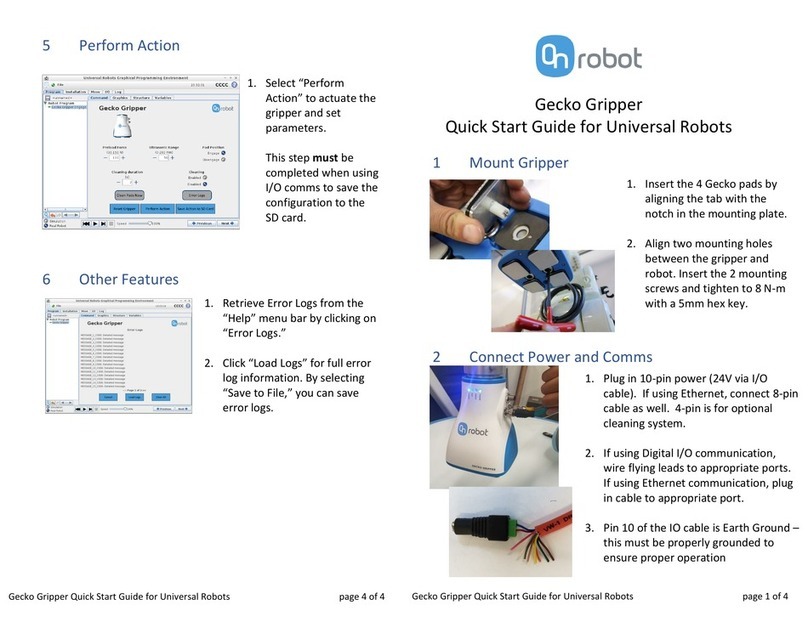

7Gripper programming............................................................................... 12