Introduction

3

6.2 Mounting........................................................................................................................ 49

6.2.1 Adapter(s).............................................................................................................. 49

6.2.2 Quick Changer options............................................................................................ 51

6.2.3 Tools......................................................................................................................53

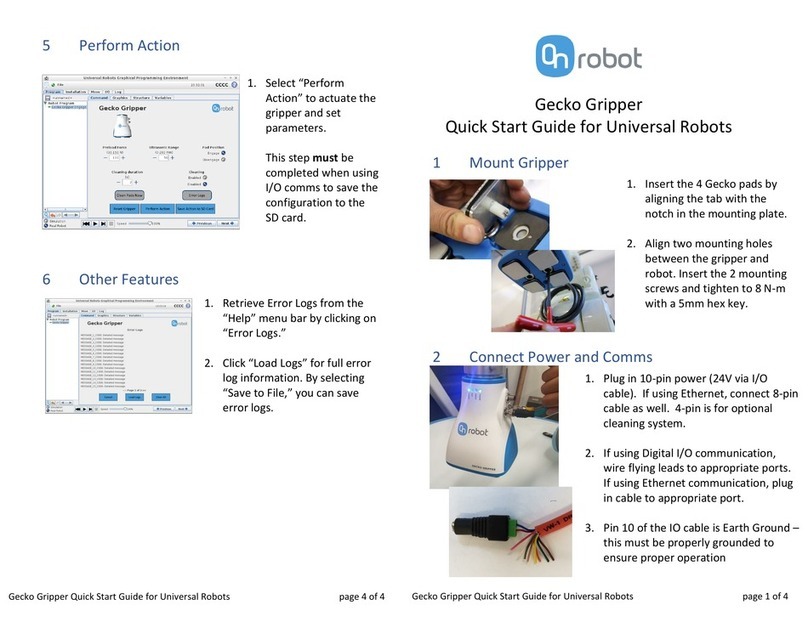

6.3 Wiring ............................................................................................................................. 59

6.3.1 Tool data................................................................................................................ 59

6.3.2 Digital I/O wires......................................................................................................59

6.3.3 Ethernet cable........................................................................................................ 63

6.3.4 Power supply..........................................................................................................63

7 Operation...............................................................................................................................65

7.1 Overview.........................................................................................................................65

7.2 Ethernet Interface setup................................................................................................... 66

7.3 Web Client....................................................................................................................... 68

7.4 OnRobot WebLogic menu................................................................................................. 70

7.4.1 Browser.................................................................................................................70

7.4.2 Program Editor....................................................................................................... 71

8 Additional Software Options................................................................................................... 77

8.1 Compute Box...................................................................................................................77

8.1.1 Interfaces............................................................................................................... 77

8.1.2 Web Client............................................................................................................. 77

8.2 EtherNet/IP .....................................................................................................................96

8.2.1 Available connections and assembly instances .........................................................96

9 Hardware Specification......................................................................................................... 124

9.1 Technical sheets............................................................................................................. 124

9.2 Mechanical Drawings ..................................................................................................... 162

9.2.1 Adapter plate(s) ................................................................................................... 162

9.2.2 Mountings............................................................................................................ 165

9.2.3 Tools.................................................................................................................... 169

9.3 Center of Gravity............................................................................................................ 179

10 Maintenance........................................................................................................................ 181

11 Warranties........................................................................................................................... 184

11.1 Patents.......................................................................................................................... 184

11.2 Product Warranty .......................................................................................................... 184

11.3 Disclaimer...................................................................................................................... 184

12 Certifications........................................................................................................................ 185

1.2 Declaration of Incorporation........................................................................................... 191