8.1.8. Screwdriver.........................................................................................................................189

8.1.9. SG.........................................................................................................................................203

8.1.10. VG10...................................................................................................................................207

8.1.11. VGC10..................................................................................................................................216

8.1.12. Compute Box...................................................................................................................228

8.1.12.1. With 1.5A Wall Adapter (36W).......................................................................... 228

8.1.12.2. With 5A Wall Adapter (120W).......................................................................... 228

8.1.12.3. Compute Box I/O interface.............................................................................. 229

8.2. Mechanical Drawings.................................................................................................................229

8.2.1. Adapter Plate.................................................................................................................... 229

8.2.2. Angle Bracket.................................................................................................................. 230

8.2.3. Mountings.......................................................................................................................... 231

8.2.3.1. Quick Changer - Robot Side.............................................................................. 231

8.2.3.2. Quick Changer for I/O - Robot Side...............................................................232

8.2.3.3. Dual Quick Changer...........................................................................................233

8.2.3.4. HEX-E/H QC..........................................................................................................234

8.2.4. Tools................................................................................................................................... 235

8.2.4.1. 3FG15...................................................................................................................... 235

8.2.4.2. RG2-FT...................................................................................................................237

8.2.4.3. RG2.........................................................................................................................238

8.2.4.4. RG6.........................................................................................................................239

8.2.4.5. Screwdriver.......................................................................................................... 240

8.2.4.6. SG............................................................................................................................ 241

8.2.4.7. VG10........................................................................................................................242

8.2.4.8. VGC10.................................................................................................................... 244

8.2.4.9. Quick Changer - Tool Side............................................................................... 246

8.2.4.10. Compute Box......................................................................................................246

8.3. COG, TCP...................................................................................................................................... 246

8.3.1. 3FG15...................................................................................................................................247

8.3.2. HEX-E/H QC......................................................................................................................247

8.3.3. RG2-FT............................................................................................................................... 247

8.3.4. RG2..................................................................................................................................... 248

8.3.5. RG6.....................................................................................................................................248

8.3.6. Screwdriver.......................................................................................................................248

8.3.7. SG........................................................................................................................................ 248

8.3.8. VG10................................................................................................................................... 250

8.3.9. VGC10................................................................................................................................ 250

8.3.10. Angle Bracket.................................................................................................................250

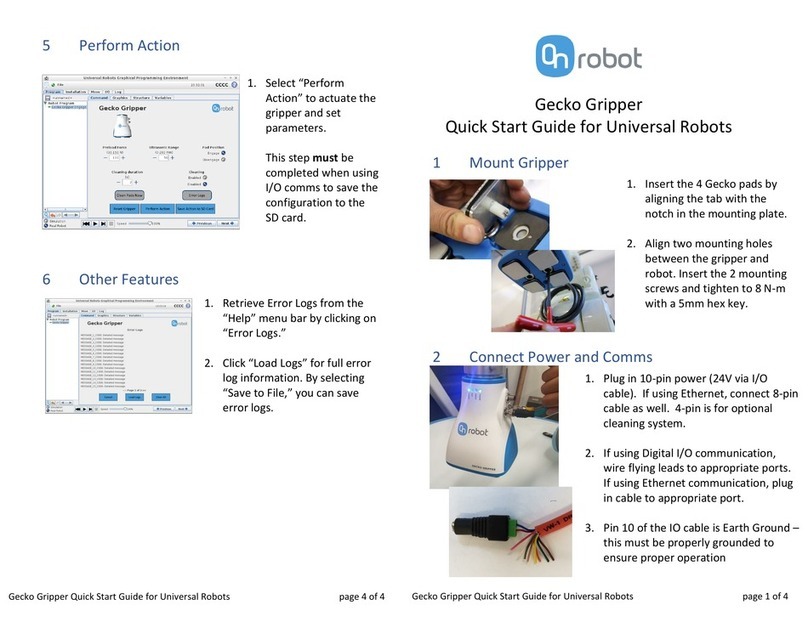

9. Maintenance..............................................................................................................................253

9.1. 3FG15...............................................................................................................................................253

9.2. RG2/6............................................................................................................................................. 253

9.3. RG2-FT........................................................................................................................................... 253

5