VG10 User Manual 1.1.0

Page 6 of 40

Table of contents

Technical sheet.............................................................................................................4

Features.......................................................................................................................4

Typical applications .....................................................................................................5

Operating conditions...................................................................................................5

What’s in the box? ........................................................................................................5

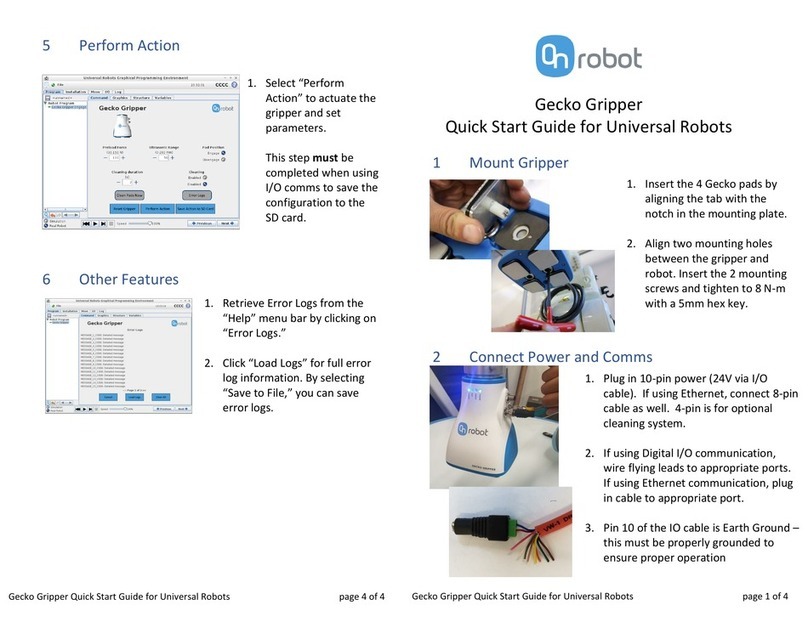

1 Quick guides...............................................................................................................8

Installation...................................................................................................................8

Troubleshooting ..........................................................................................................9

Updating software.......................................................................................................9

Uninstalling............................................................................................................... 10

2 Software specification .......................................................................................... 10

URCap ....................................................................................................................... 10

The Installation Screen ......................................................................................... 11

Structures ............................................................................................................. 12

VG10 Grip ............................................................................................................. 12

VG10 Release........................................................................................................ 14

Script commands...................................................................................................... 15

VG10_grip (channel, vacuum, timeout, alert)...................................................... 15

VG10_release(channel, timeout, autoidle) .......................................................... 15

VG10_get_vacuum(channel)................................................................................ 16

VG10_calibrate_ain()............................................................................................ 16

VG10_idle(channel).............................................................................................. 16

MODBUS RTU ........................................................................................................... 17

Settings................................................................................................................. 17

Function codes...................................................................................................... 17

Registers ............................................................................................................... 18

Manual control......................................................................................................... 20

3 Hardware specification ......................................................................................... 21

Vacuum cups and fittings ......................................................................................... 22