2

• Saving data to the non-volatile memory

Do not turn off the power supply while writing the data to the

non-volatile memory, and also do not turn off at least for 5 seconds

after writing the data. Doing so may abort writing the data and cause

an EEPROM error alarm to generate. The non-volatile memory can

be rewritten approximately 100,000 times.

• Overvoltage alarm by regeneration energy

The overvoltage alarm will generate depending on the operating

condition. When an alarm is generated, review the operating

conditions.

• Do not perform push-motion operation with the DGⅡ

Series.

Doing so may result in damage to the motor or gear part.

• When performing sensorless return-to-home operation

upward in a vertical direction with the EAS4 type (ball screw

lead 12 mm), keep the load mass to be less than 4 kg.

If the load mass is 4 kg or more, the actuator cannot push up to the

position of the mechanical stopper, causing irregularity in the

stopping accuracy of return-to-home.

Preparation

Checking the product

Verify that the items listed below are included. Report any missing or

damaged items to the branch or sales office from which you

purchased the product.

• Driver.............................................................................. 1 unit

• CN1 connector

(for power supply input terminals; 5 pins)...................... 1 pc.

• CN5 connector (for sensor signals; 5 pins) ..................... 1 pc.

• CN8 connector (for input signals; 9 pins) ....................... 1 pc.

• CN9 connector (for output signals; 7 pins) ..................... 1 pc.

• Motorized Actuator Driver

OPERATING MANUAL (this document)...................... 1 copy

Combinations of actuators and drivers

• indicates A(single shaft) or B(double shaft).

• indicates the table type (Xor Y).

• indicates D(ball screw lead: 12 mm) or E(ball screw lead:

6 mm).

• indicates the stroke (If the stroke is 50 mm, enter 005).

• indicates the supplied cable length.

• DGⅡSeries

Model Actuator model Driver model

DG60-ARKD-DGM60-ARK LSD-KD

• EAS Series

Model Actuator model Driver model

EAS4--KD-EASM4K

EAS4-M-KD-EASM4MK

EAS6--KD-EASM6K

EAS6-M-KD-EASM6MK

LSD-KD

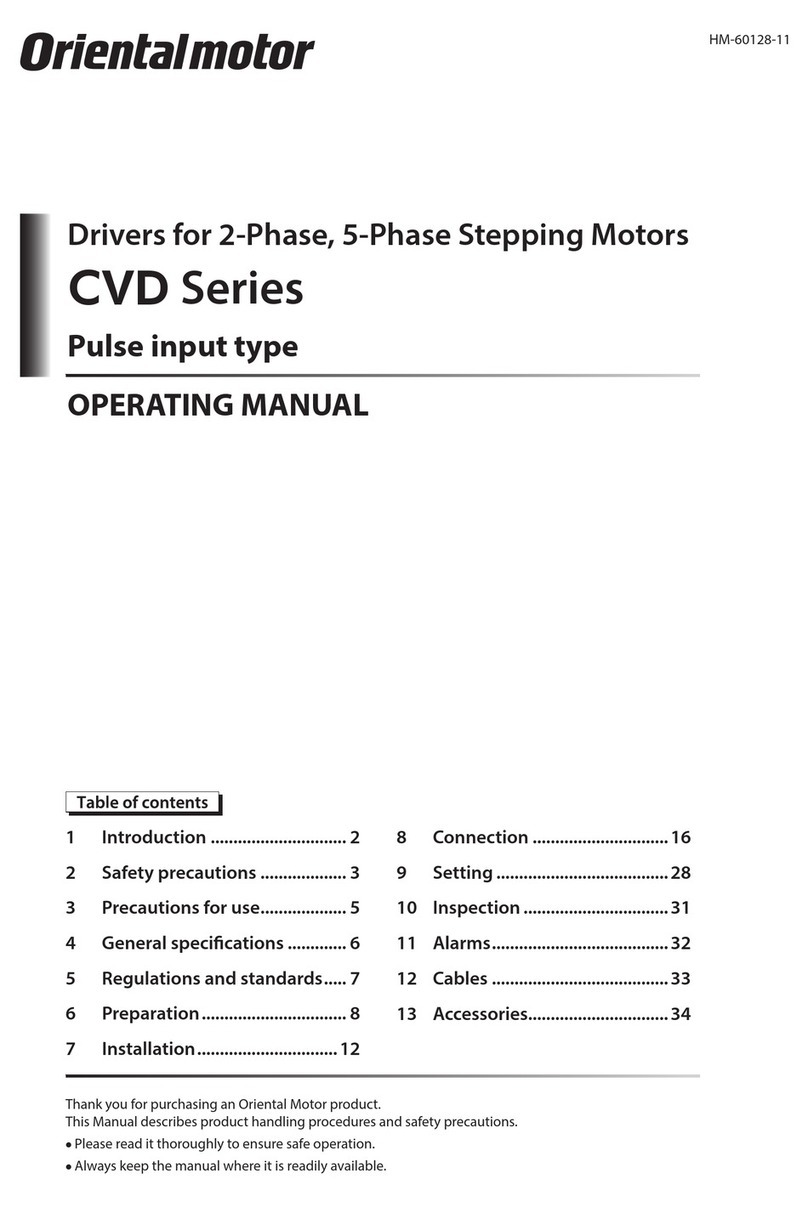

Names and functions of parts

Transmission rate setting

switch (SW2)

Address number setting

switch (SW1)

Data edit connector

(CN3)

Motor connector

(CN2)

CN1

Battery connector

(CN4)

POWER/ALARM LED C-DAT/C-ERR LED

Output signal connector

(CN9)

Input signal connector

(CN8)

Sensor signal connector

(CN5)

Power supply input

terminals

Electromagnetic

brake terminals

Frame Ground

Terminal

DIN lever

RS-485 communication

connectors (CN6/CN7)

Function setting switches (SW3)

Name Description

POWER/ ALARM LED

• POWER (Green): This LED is lit while

the main power is input.

• ALARM (Red): This LED will blink when

an alarm generates. It is possible to

check the generated alarm by counting

the number of times the LED blinks.

C-DAT/C-ERR LED

• C-DAT (Green): This LED will blink or

illuminate steadily when the driver is

communicating with the master station

properly via RS-485 communication.

• C-ERR (Red): This LED will illuminate

when a RS-485 communication error

occurs with the master station.

Address number

setting switch (SW1)

Use this switch when controlling the

system via RS-485 communication. Using

this switch in combination with the

SW3-No.1 of the function setting switch,

the address number (slave address) of

RS-485 communication can be set.

(Factory setting: 0)

Transmission rate

setting switch (SW2)

Use this switch when controlling the

system via RS-485 communication. Set

the transmission rate of RS-485

communication.

(Factory setting: 7)

Function setting

switches (SW3)

Use this switch when controlling the

system via RS-485 communication.

No.1: Using this switch in combination with

the address number setting switch

(SW1), the address number (slave

address) of RS-485 communication

can be set. (Factory setting: OFF)

No.2: The transmission rate of RS-485

communication can be set.

(Factory setting: OFF)

No.3: Not used.

No.4: Set the termination resistor (120 Ω)

of RS-485 communication.

(Factory setting: OFF)